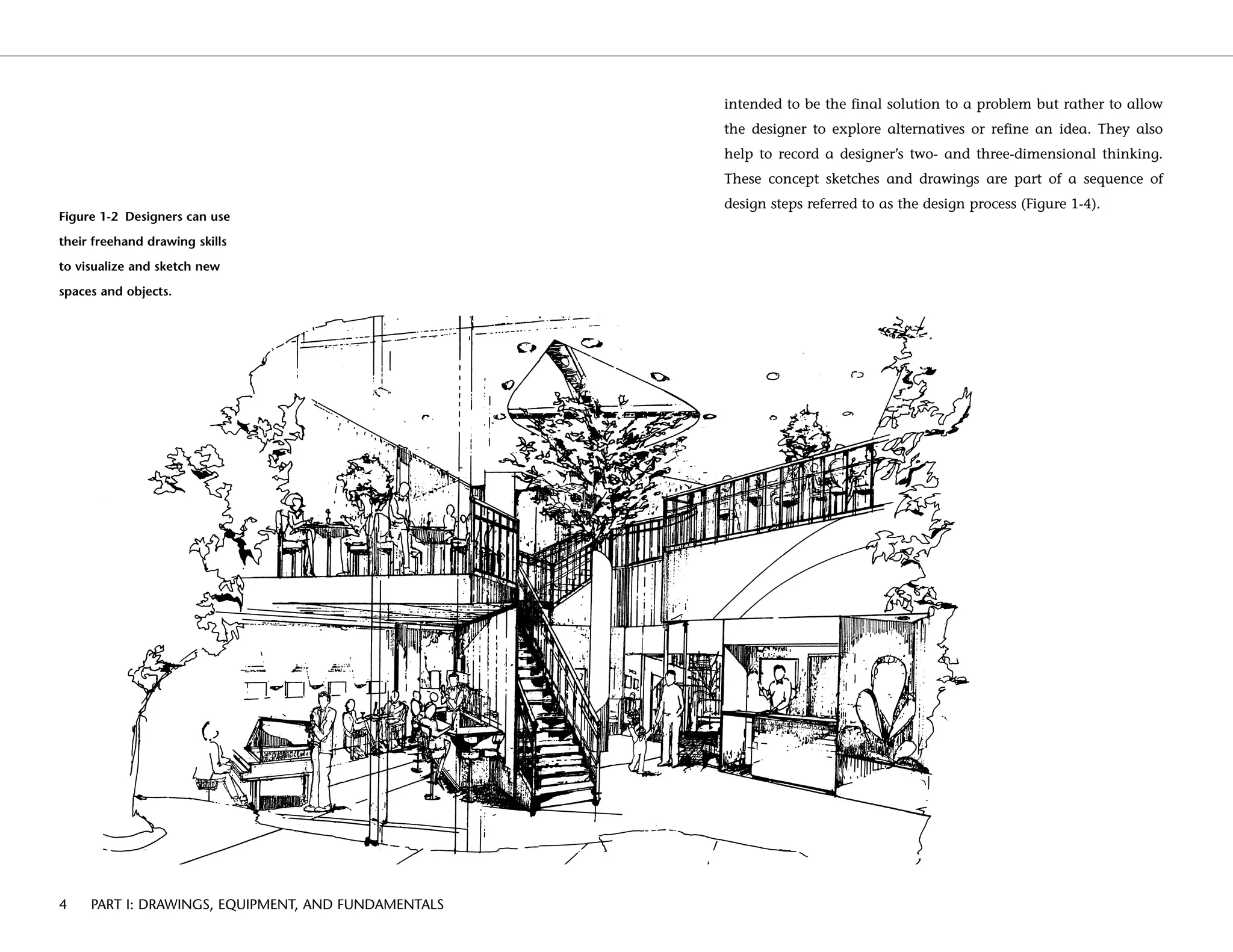

The document discusses construction drawings and details for interior design projects. It provides an overview of drawing as a communication tool in three main contexts: for idea generation, as a design and presentation medium, and as a guide for construction. For idea generation, designers use sketches and drawings to visualize and explore design solutions. Presentation drawings are used to convey a design concept to clients. Construction drawings precisely communicate how to build or install a project and include details, dimensions, and materials. The book is intended to provide guidance on preparing construction documents for interior design students and professionals.

![CHAPTER 9: SPECIALTY DRAWINGS AND DETAILS 137

wood fuel. In fact, there is now more of an emphasis on using gas

fireplaces instead of wood-burning units for both convenience and

reduction of air pollution.

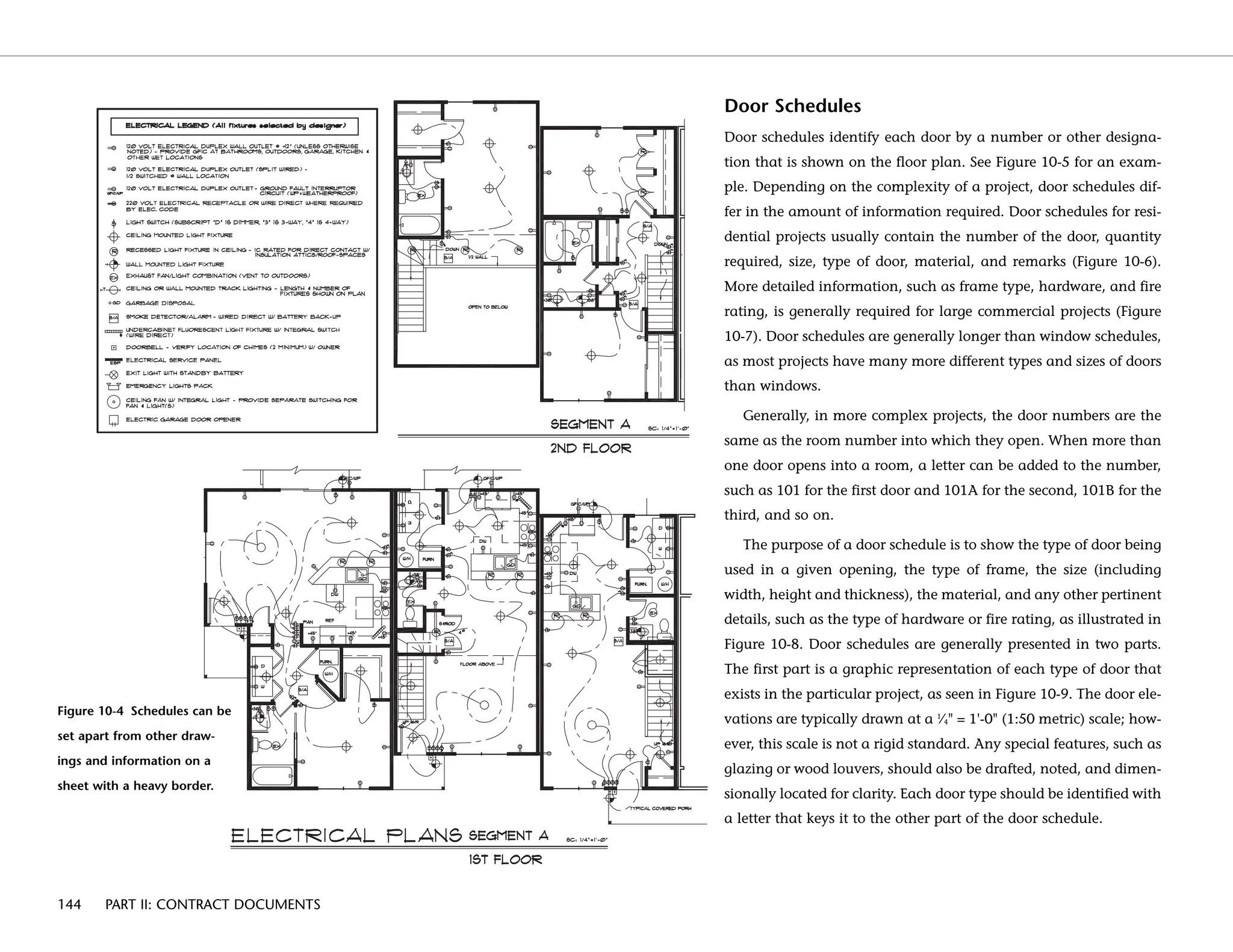

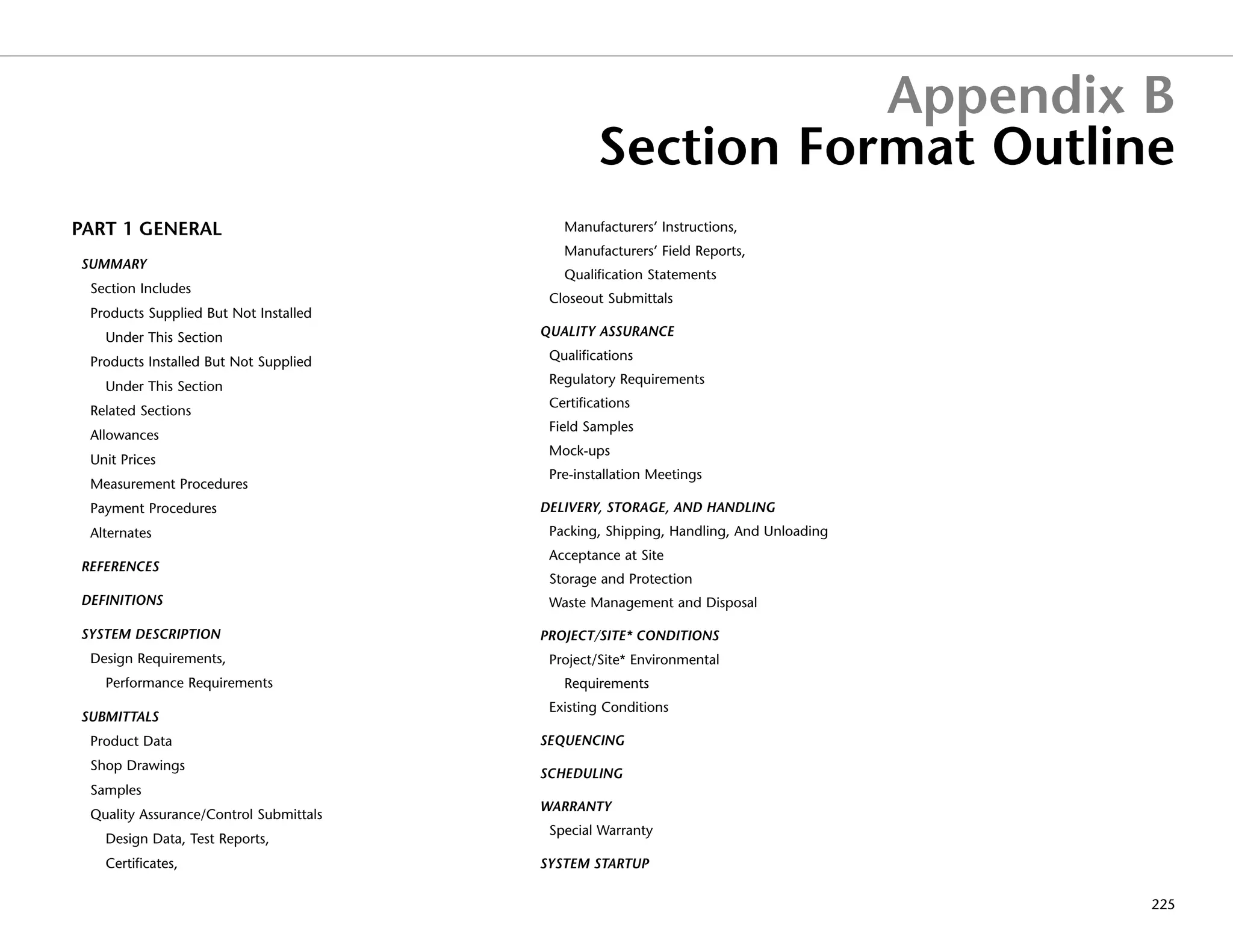

Wood-burning fireplaces have been constructed for centuries by

skilled masons and bricklayers. The proportions and dimensions of

such fireplaces and their various parts, such as the flue and open-

ings, are based upon the laws of heat transfer, and on the various

building codes. These dimensions and assemblies have developed

over the years. Their dimensions are tabulated by various building

codes and reference manuals for site-built units and provided by

manufacturers for factory-made units (Figure 9-21).

Today, wood-burning fireplaces are of four basic types: those

completely constructed on-site; those consisting of a manufactured

firebox that is covered with masonry on the jobsite; prebuilt metal

units (commonly called zero-clearance models); and freestanding

units (Figure 9-22), including both fireplaces and wood-burning

stoves. Site-constructed units and some of the heavier types require

a structural support or foundation to rest on. Most such founda-

tions are of concrete construction.

Gas fireplaces are manufactured as modular units and are

offered with a variety of openings, similar to the wood-burning

units. Vented units are sealed from the interior space and have a

small round pipe that vents the fumes to the exterior, either verti-

cally or horizontally through an exterior wall. Nonvented models

are completely sealed, with no exhausting of fumes.

Scale of Drawings

The floor plans usually show the location of the fireplace, its

hearth, and basic dimensions at a scale of 1

⁄8" = 1'-0" (1:100 metric)

or 1

⁄4"=1'-0" (1:50 metric). These plan views are simplistic, and usu-

ally cross-referenced to more detailed drawings done at a larger 12/99 HEAT-N-GLO ï (612) 985-6000 ï www.heatnglo.com K-8

RHW-56

56" ROYAL HEARTH FIREPLACE

SPECIFICATIONS

Model

RHW-56

Height Front Width Back Width Depth

Glass

Size

Actual Framing Actual Framing Actual Framing Actual Framing

Inches 60 3/8 49 1/2 55 7/8 56 7/8 37 56 7/8 29 1/8 30 5/8 48 x 28

Refer to installation manual for detailed specifications on installing this product.

14 [356MM]

29 1/8 [740MM]

16 3/8 [416MM]

37 [940MM]

18 1/2 [470MM]

56 7/8 [1445MM] 30 5/8 [778MM]

49 1/2 [1257MM]

5 3/8 [137MM]

11 1/8 [283MM]

6 1/8 [156MM]

60 3/8 [1534MM]

80 7/8 [2054MM]

49 3/8 [1264MM]

55 7/8 [1419MM]

48 [1219MM]

7 1/4 [184MM]

42 1/2 [1080MM]

28 [711MM]

NOTE: Fireplace must be installed prior to nailing header in to place.

Figure 9-21 Wood-burning fire-

places are available in factory-made

units, in which the proportions,

dimensions, flue, openings, etc.

follow standard specifications.

09.kilmer 1/14/03 11:03 PM Page 137](https://image.slidesharecdn.com/constructiondrawingsanddetailsforinteriors-240228213636-c09b1408/75/Construction-Drawings-and-Details-for-Interiors-pdf-150-2048.jpg)