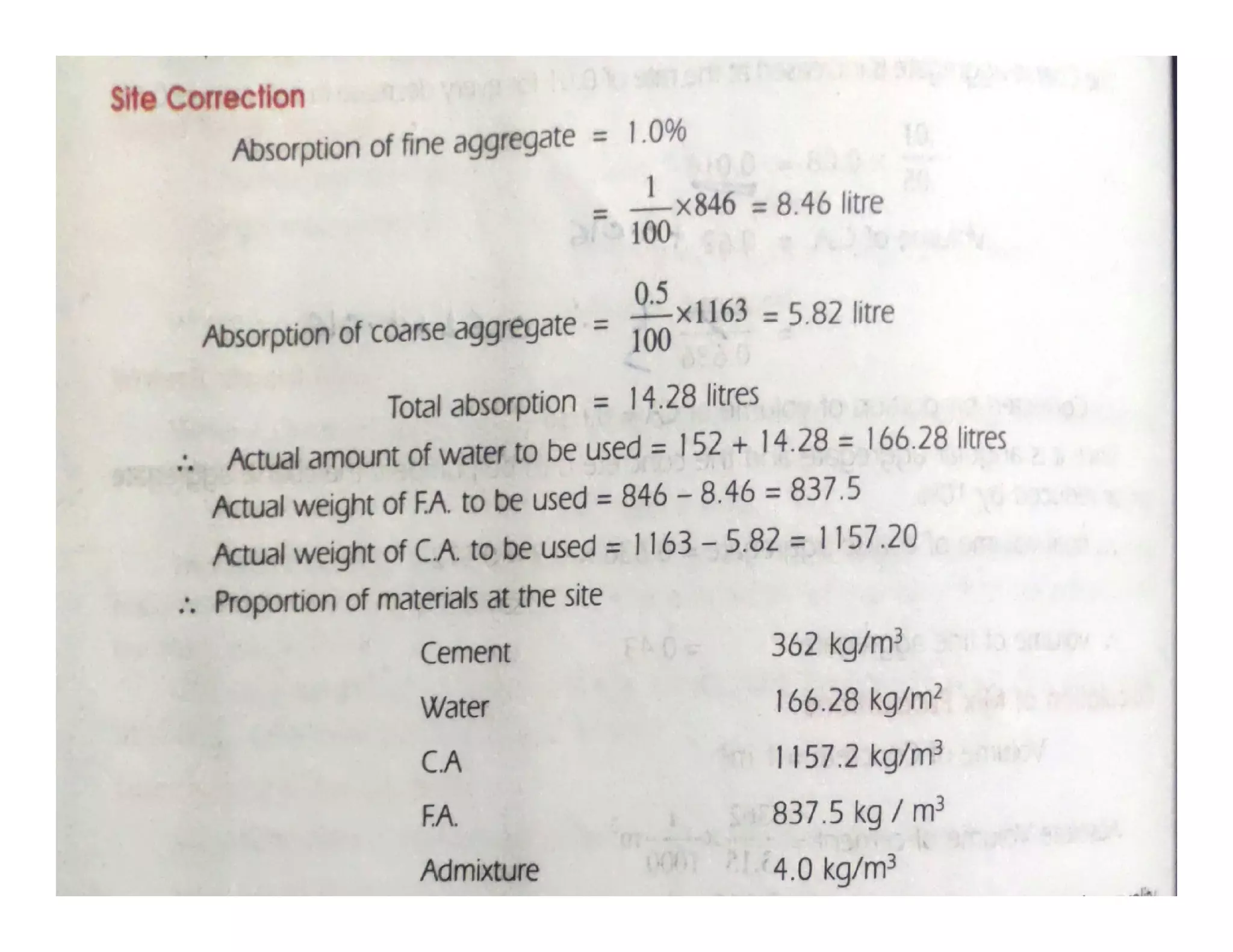

This document discusses mix design methods for concrete. It provides details on various factors that influence concrete mix design, including water-cement ratio, cement content, aggregate gradation and consistency. It describes different mix design methods such as the arbitrary method, fineness modulus method, maximum density method, and ACI and IRC recommended methods. The document also gives terminology and formulas used in statistical quality control for concrete mix design. It provides an example of designing a concrete mix for a reinforced concrete structure as per Indian standards.