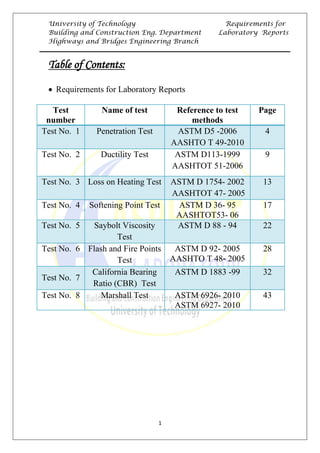

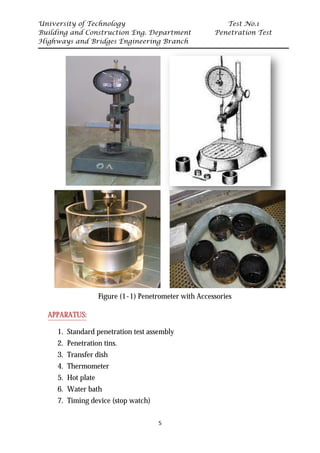

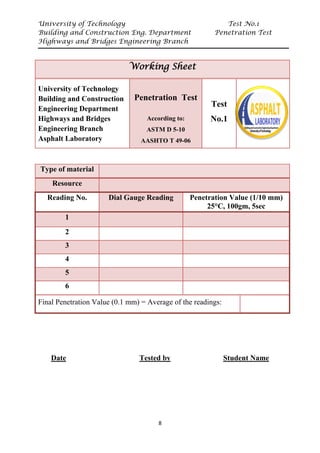

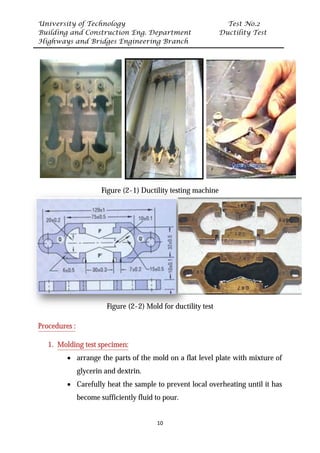

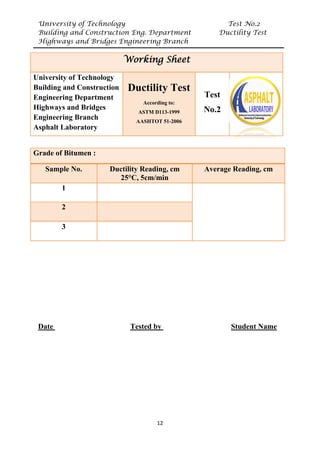

The document is a laboratory manual for asphalt testing prepared by Dr. Zaynab I. Qasim at the University of Technology, covering various tests such as penetration, ductility, loss on heating, and softening point. Each test includes objectives, principles, procedures, and grading criteria, providing technical details for students in the Building and Construction Engineering Department. The manual emphasizes the importance of proper report formatting and the analysis of results to ensure quality in engineering applications.

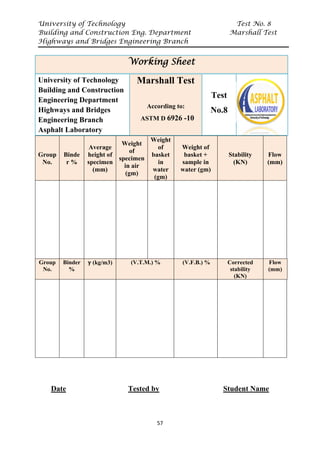

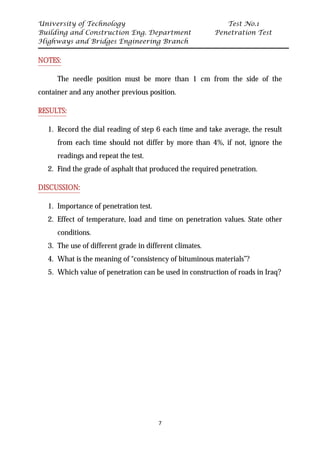

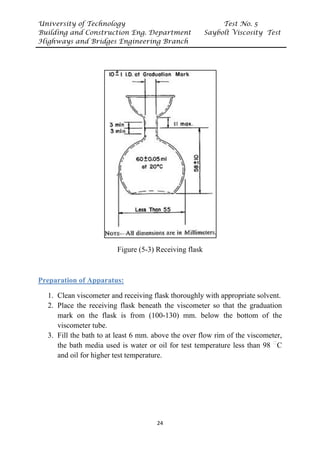

![University of Technology Test No. 5

Building and Construction Eng. Department Saybolt Viscosity Test

Highways and Bridges Engineering Branch

27

Date Tested by Student Name

Working Sheet

University of Technology

Building and Construction

Engineering Department

Highways and Bridges

Engineering Branch

Asphalt Laboratory

Saybolt

Viscosity Test

According to:

ASTM D 88- 99

Test

No.5

Grade of Bitumen :

Viscometer

No.

Testing

Temperature

Efflux Time [SUV,SFV] Kinematic Viscosity

"centistokes" (cSt)

(min) (sec)](https://image.slidesharecdn.com/1583661374288143-240324191004-a39f34ec/85/Asphalt-Experiments-Guide-Laboratory-34-320.jpg)