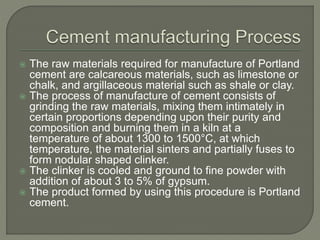

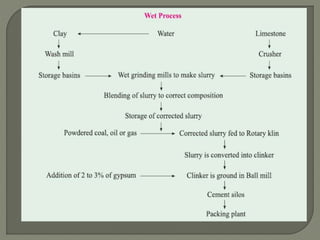

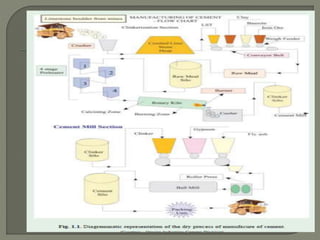

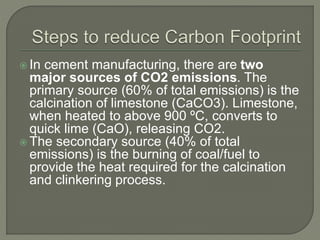

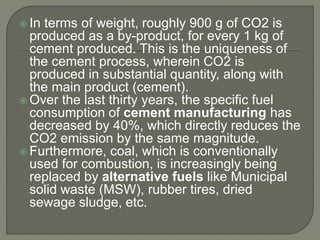

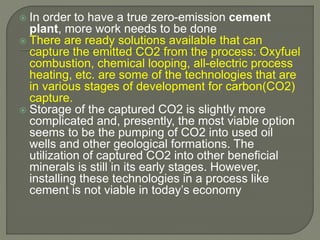

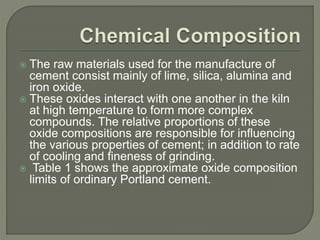

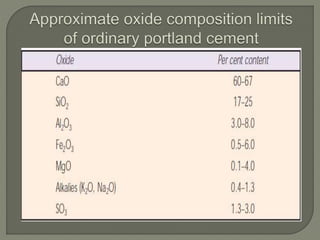

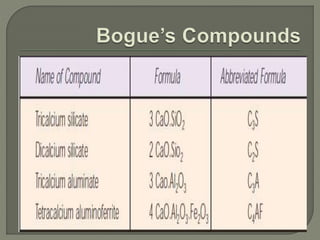

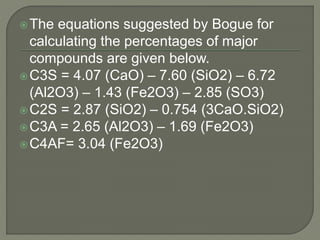

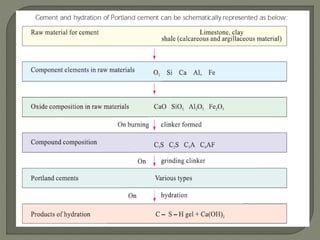

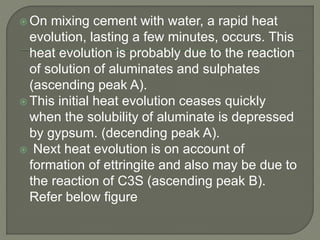

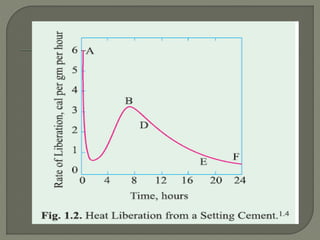

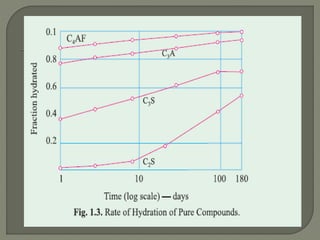

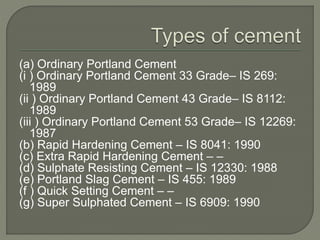

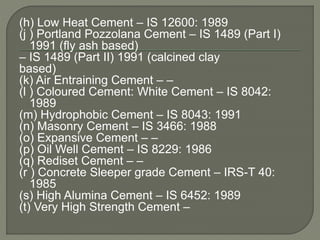

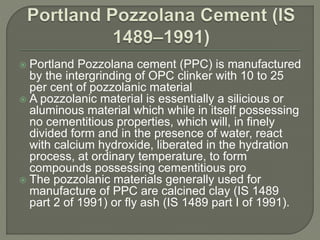

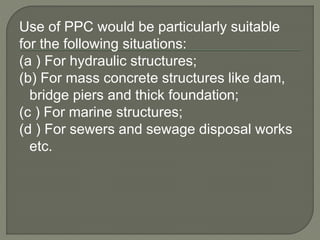

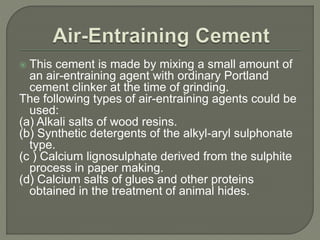

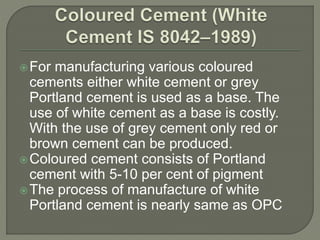

The document provides a comprehensive overview of cement manufacturing, including its chemical composition, hydration process, types of cement, and methods to reduce carbon emissions during production. It discusses the historical development of cement production techniques, emphasizes the importance of raw material composition, and describes the various types of cement and their properties. Additionally, it highlights the environmental challenges faced by the industry and suggests solutions for achieving sustainability in cement production.