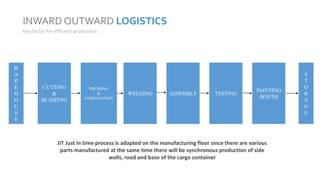

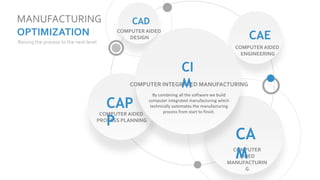

This document provides information on the computer integrated manufacturing of cargo containers. It describes the technological processes involved such as cutting, welding, pressing, assembly, painting, and testing. It also discusses topics like material consumption, customer requirements, logistics possibilities, and the benefits of flexible manufacturing systems and computerization for container production. Overall, the document outlines the end-to-end manufacturing process for cargo containers using computer integrated approaches.