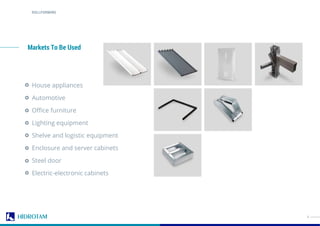

Hidrotam is a specialized manufacturer with over 21 years of experience, offering innovative solutions in sheet metal production across various sectors including automotive and house appliances. They focus on productivity, having completed over 200 R&D projects, and provide fully automated production lines with CE certification for multiple applications. Their technology includes advanced CAD/CAM/PLM systems, custom-designed lines, and efficient CNC bending and rolling systems to minimize waste and enhance operational efficiency.