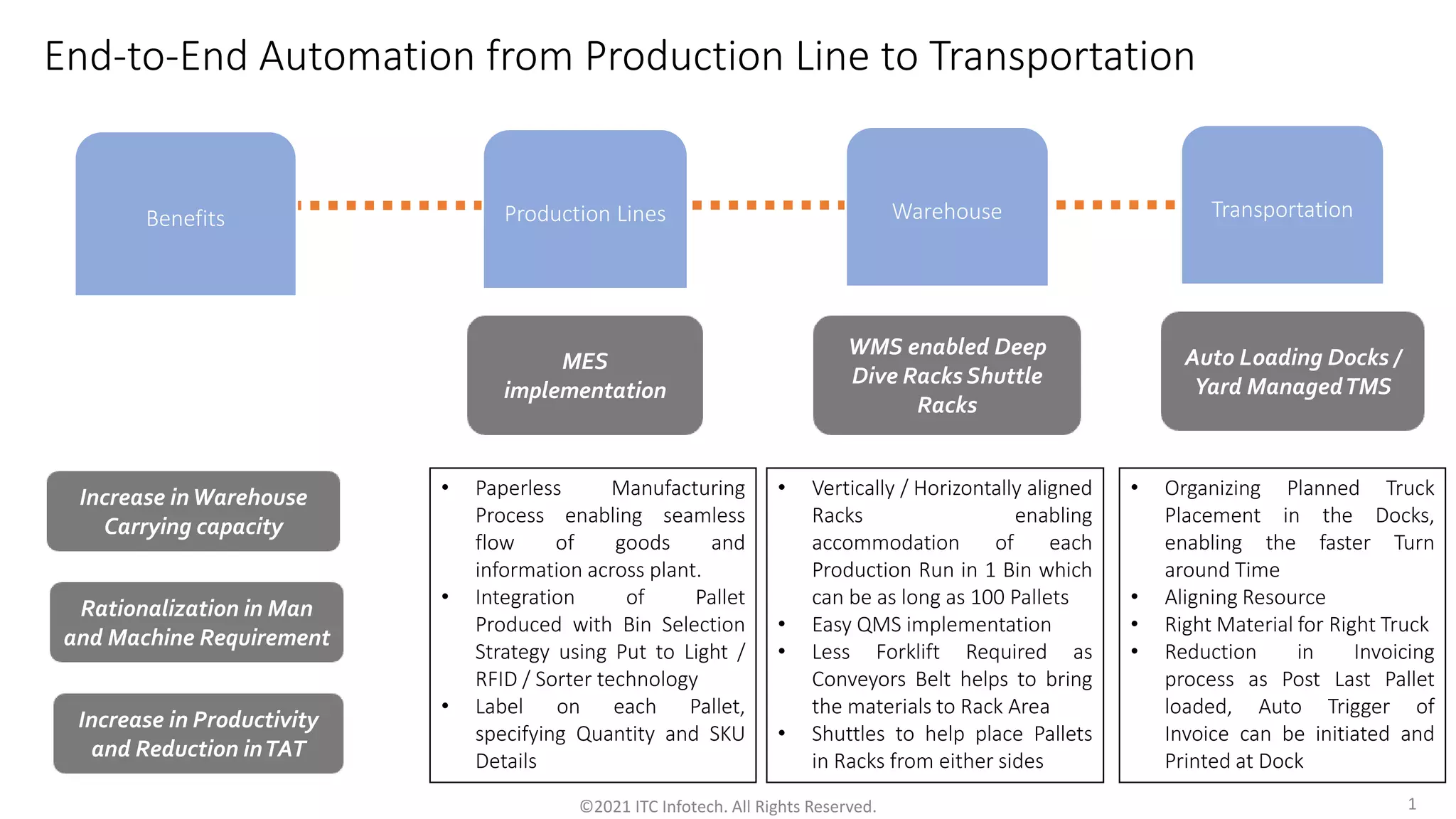

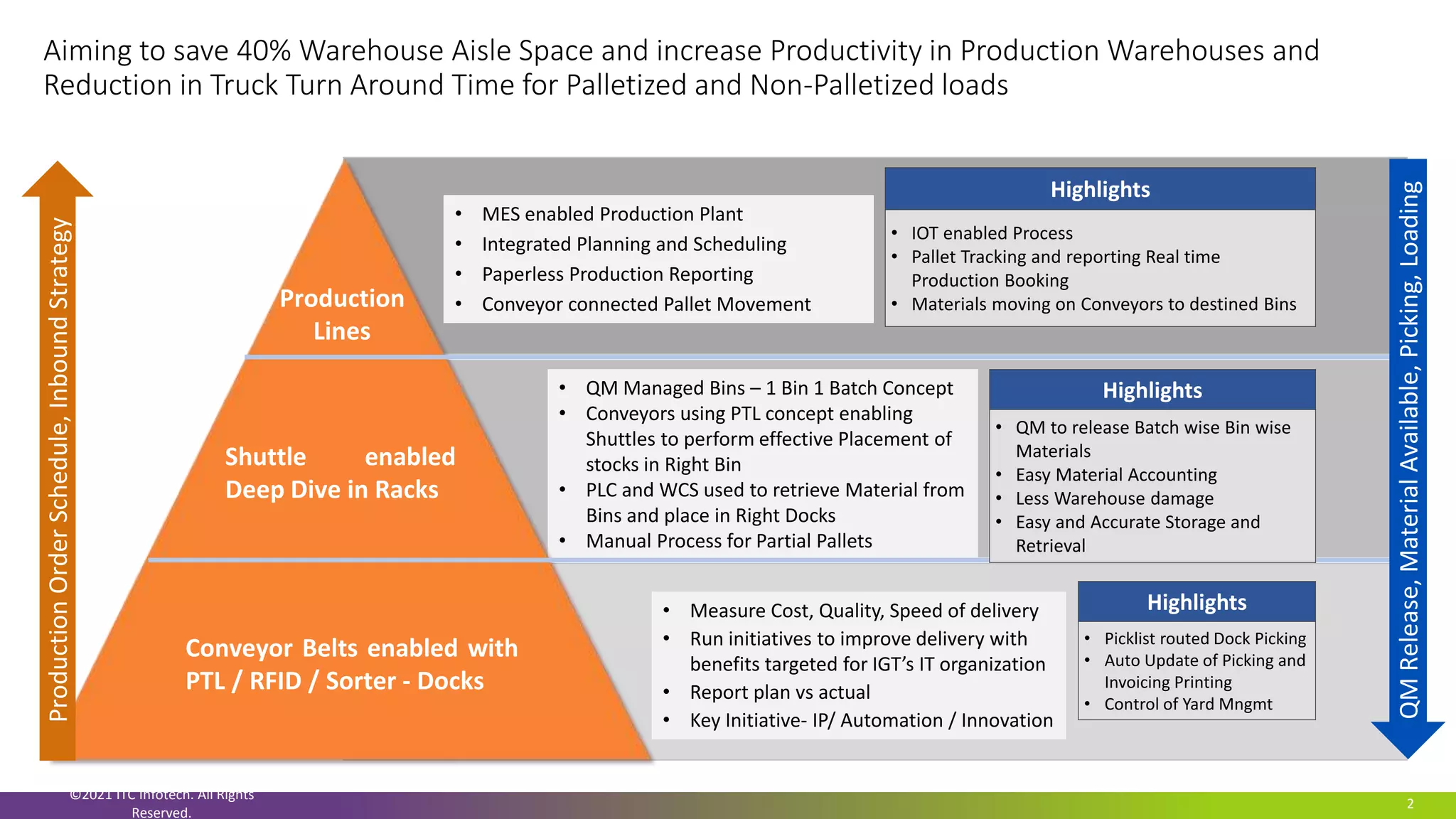

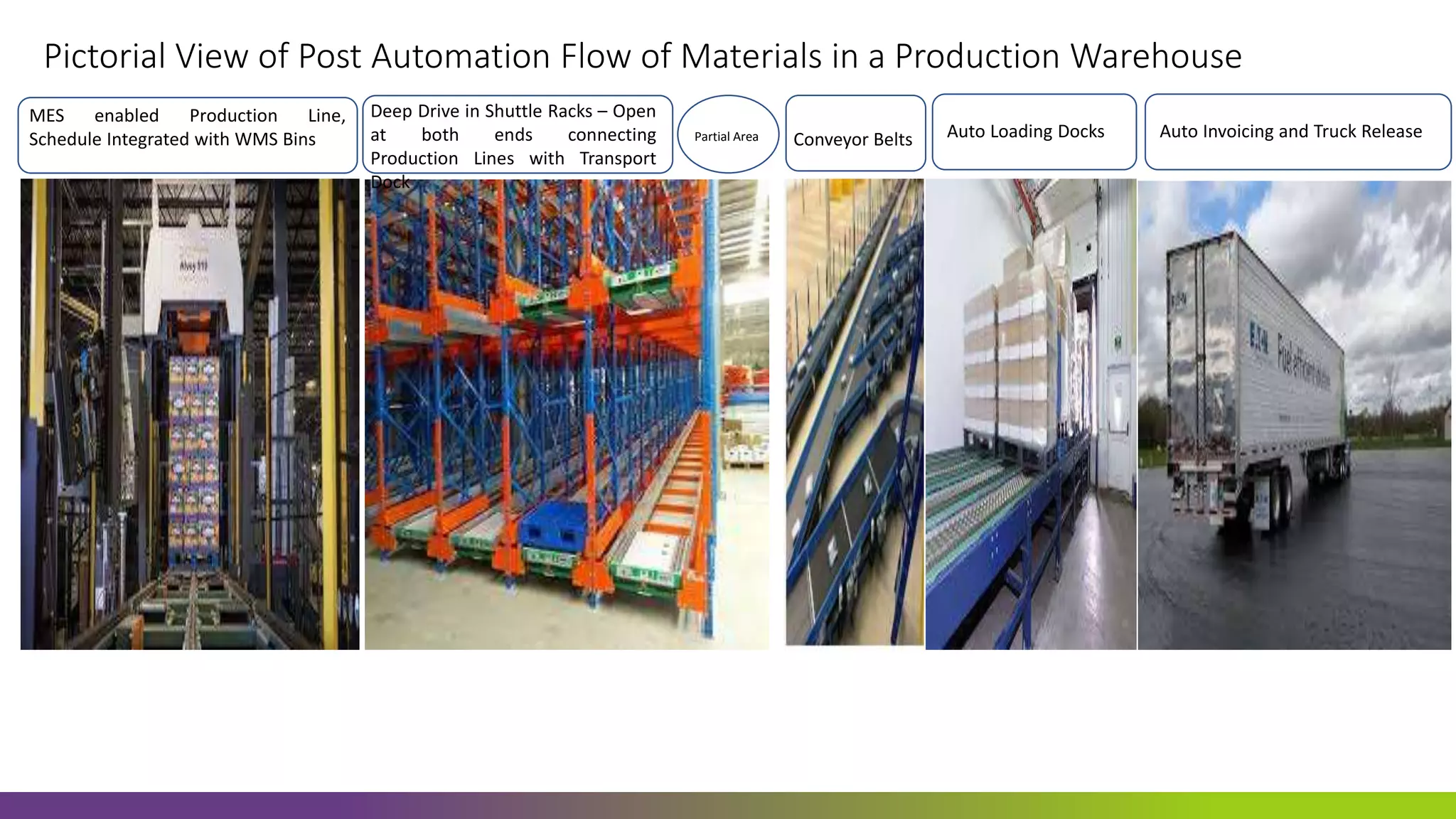

The document discusses end-to-end automation from production lines to transportation in a warehouse. Key benefits include increasing warehouse carrying capacity and productivity while reducing manpower requirements and turnaround time. The automation integrates production, warehouse management, and transportation management systems to enable paperless tracking of goods and information from production to shipping. Pallets are automatically loaded onto conveyor belts and sorted into bins, then retrieved and sent to docks for loading onto trucks, with invoices automatically generated.