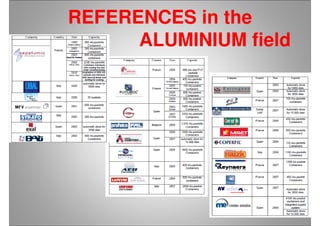

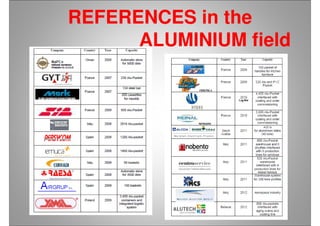

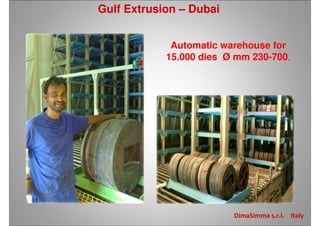

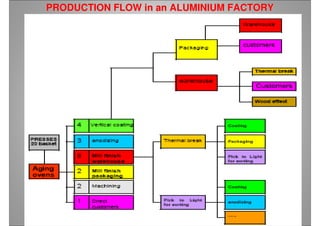

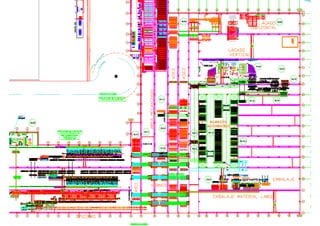

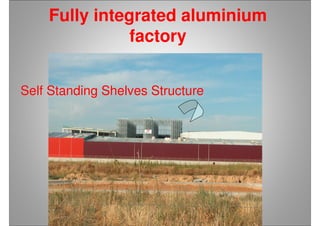

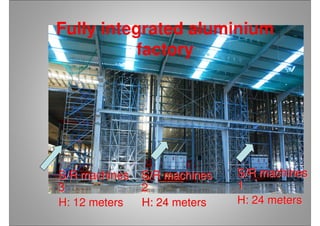

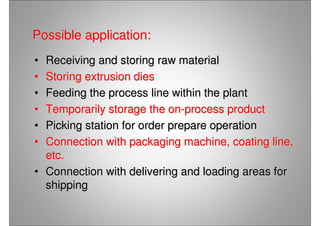

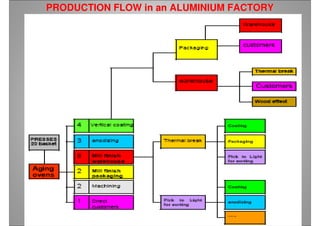

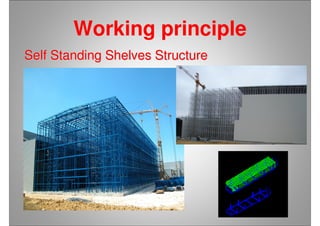

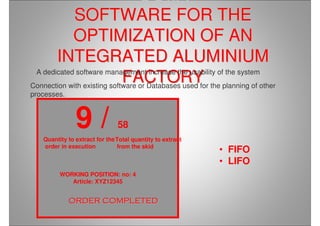

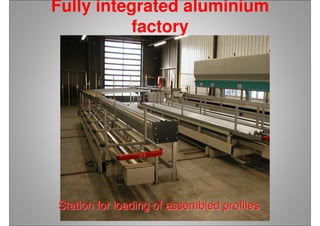

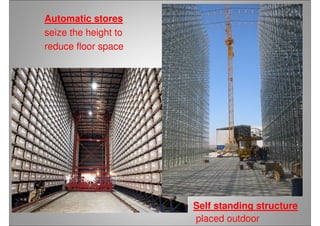

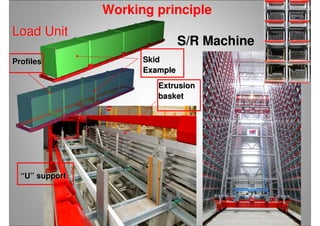

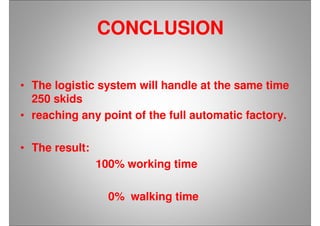

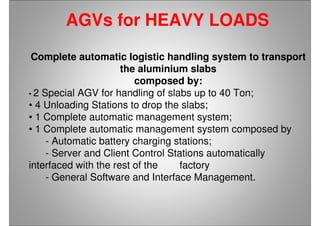

Dimasimma specializes in integrated logistics solutions and automation systems, particularly in the aluminium industry, to enhance production efficiency and competitiveness. The company has developed advanced technology for automatic warehouses and handling systems, strengthening collaboration among SMEs in Italy's Emilia-Romagna region, and has extensive references in various sectors. Their mission includes maximizing space and efficiency, reducing labor, and ensuring product safety through innovative systems and after-sale services.