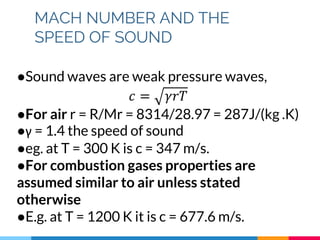

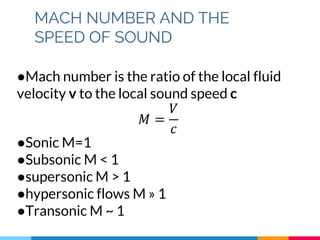

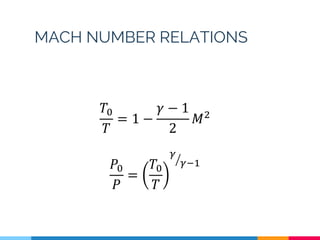

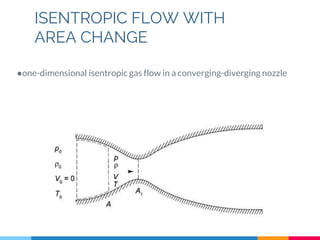

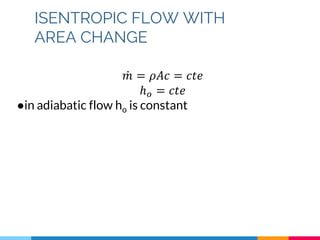

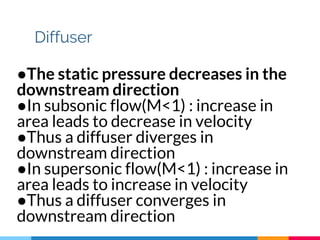

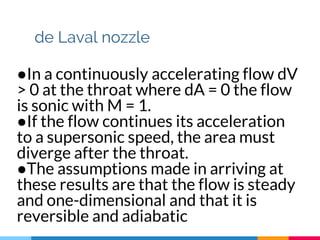

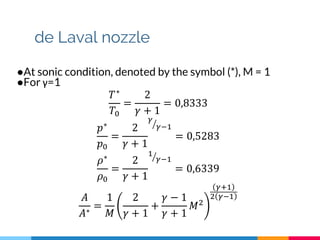

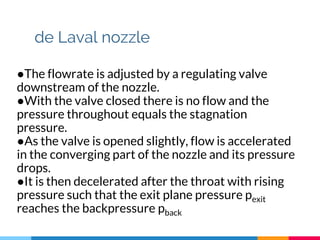

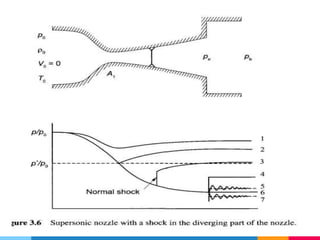

This lecture covers compressible fluid flow through nozzles. It defines key concepts like Mach number and how it relates to the speed of sound. It describes isentropic flow through converging-diverging nozzles and how properties vary with Mach number. It also discusses diffusers, De Laval nozzles, and how choking occurs when flow reaches Mach 1 at the throat. The lecture concludes with a brief discussion of supersaturation in nozzle flows.