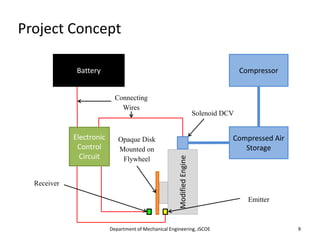

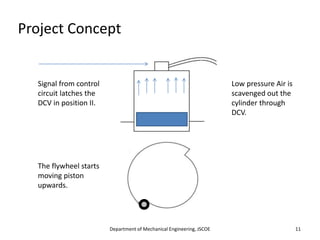

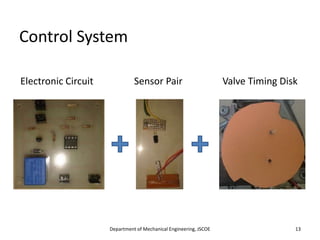

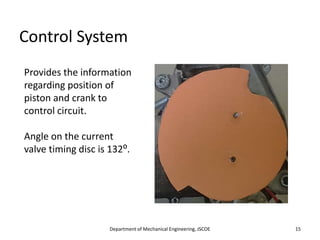

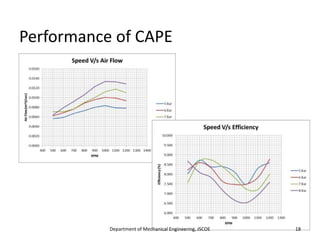

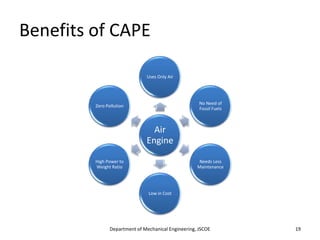

The document describes a project to convert a conventional two-stroke spark ignition engine to run on compressed air. The project aims to develop a zero-pollution compressed air powered engine (CAPE) as an alternative energy solution. A literature review found previous research and commercial examples of CAPE technology. The design features of the project include modifications to the cylinder head, an electronic control system, and pneumatic circuit to control compressed air flow. Testing showed the CAPE produces power while eliminating pollution, with benefits of using only air, lower maintenance needs, and no fossil fuels. Future work may include multi-cylinder versions with improved air recirculation and higher torque.