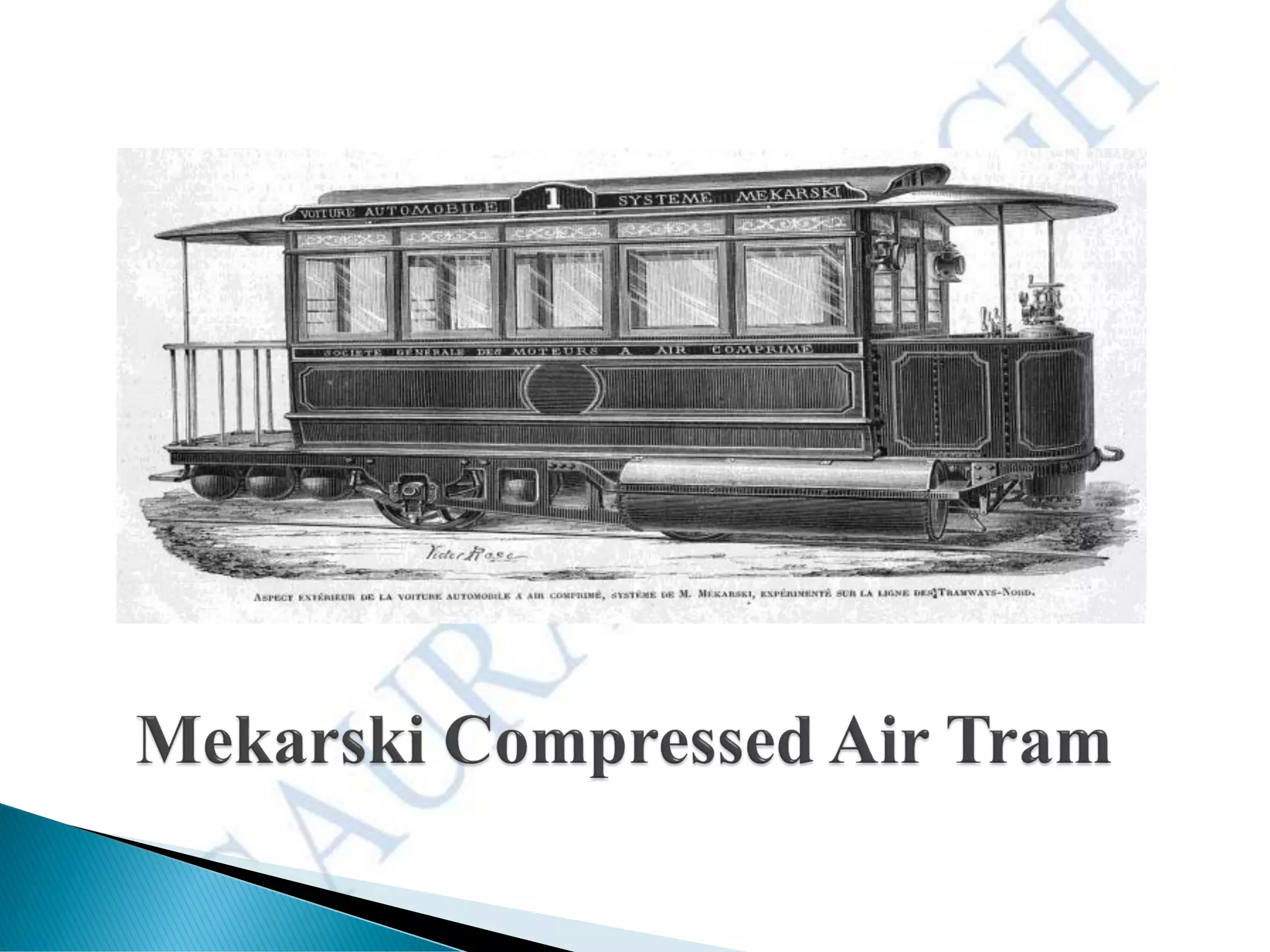

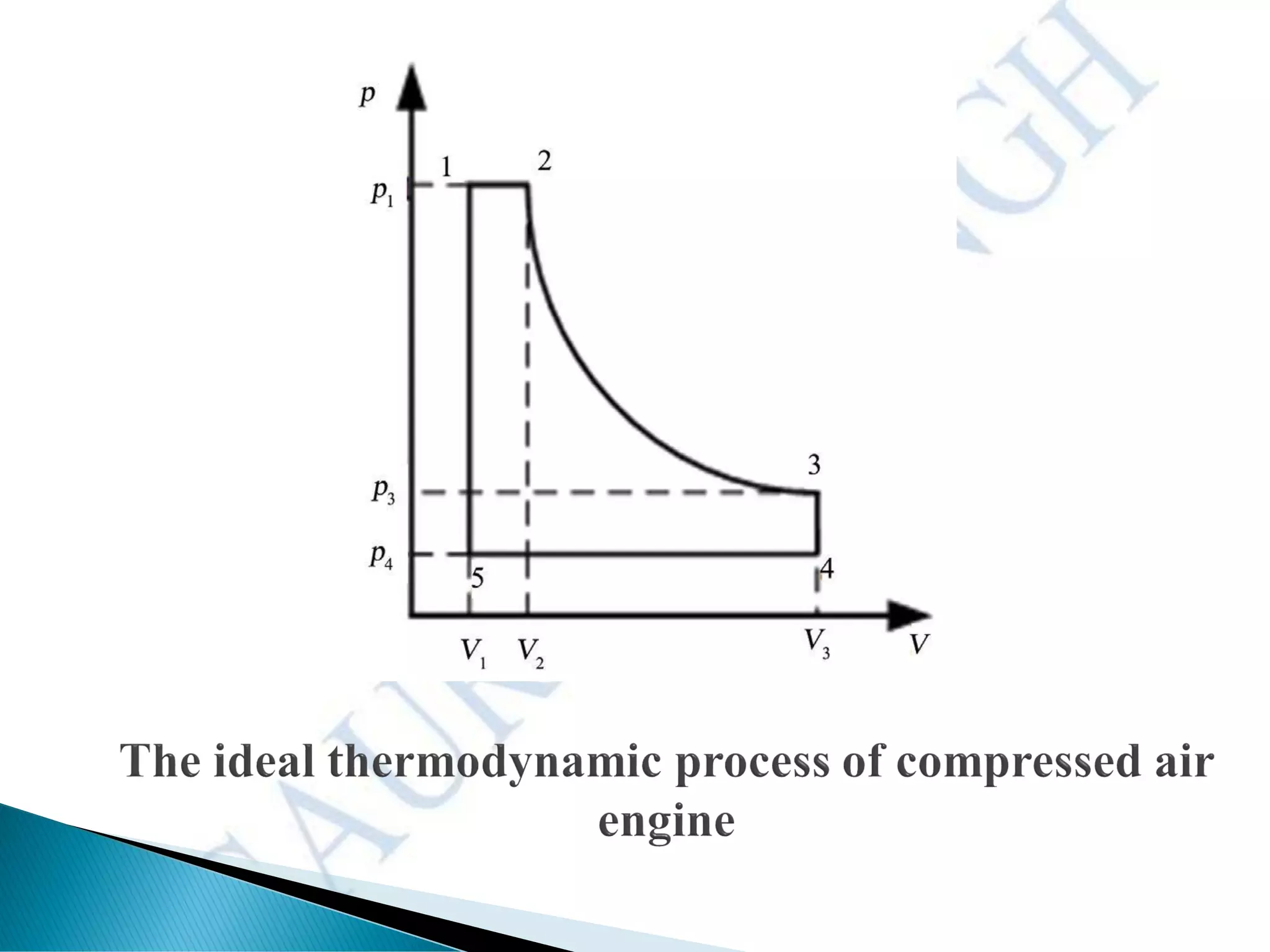

This document provides an overview of compressed air engines. It begins with an introduction describing how compressed air engines can help reduce environmental problems from fossil fuel usage. It then defines what an engine is and provides a brief history of compressed air engines dating back to the late 1600s. The document goes on to describe how a compressed air engine works, involving intake and exhaust valves and the conversion of compressed air into mechanical motion. It also discusses Tata Motor's plans to develop an Indian car powered by compressed air. Advantages include not requiring gasoline while disadvantages include limited refueling speed and capacity. The conclusion states compressed air technology could be a viable alternative fuel option.