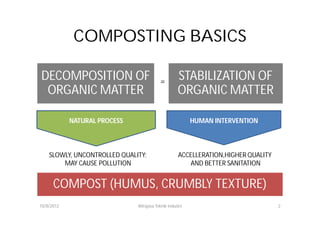

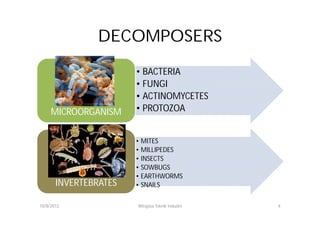

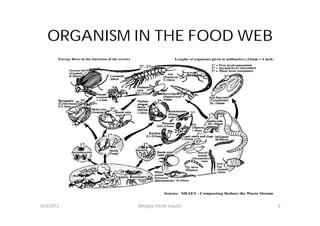

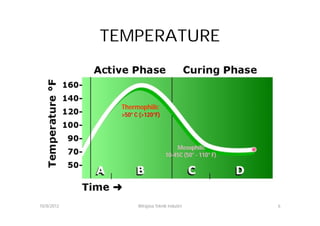

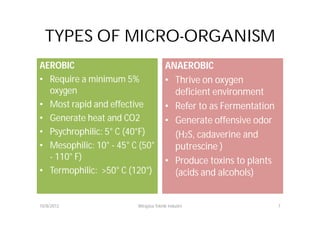

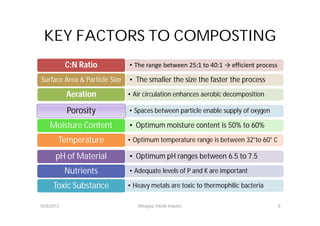

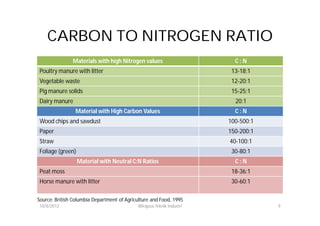

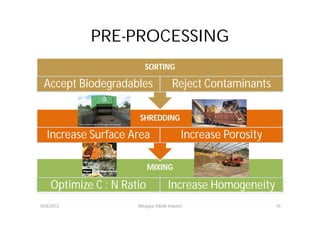

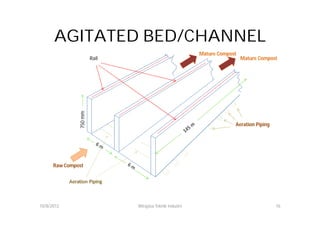

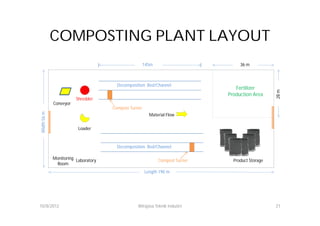

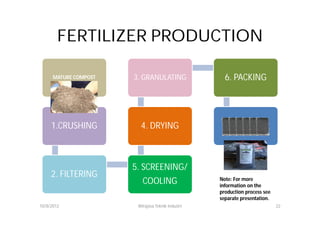

The document provides an overview of composting, detailing the decomposition process of organic matter and the role of microorganisms like bacteria and fungi in compost production. Key factors such as carbon to nitrogen ratio, moisture content, and aeration are discussed, along with different composting methods including passive and in-vessel composting. The document also outlines pre-processing steps, composting plant layout, and a marketing strategy for compost products.