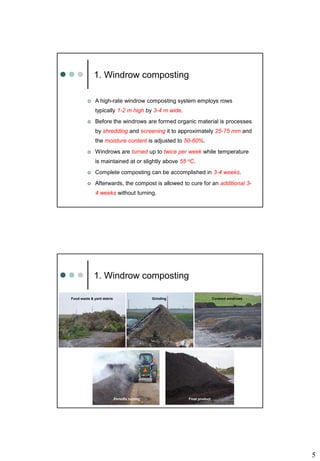

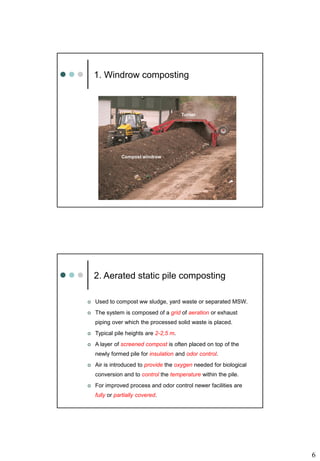

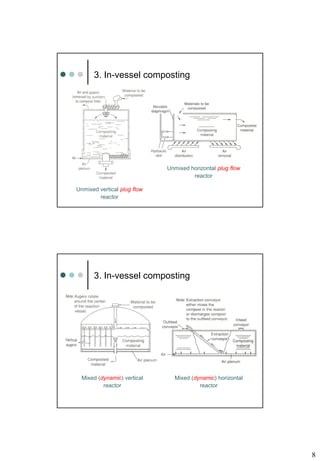

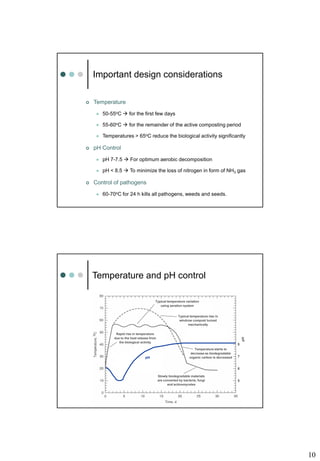

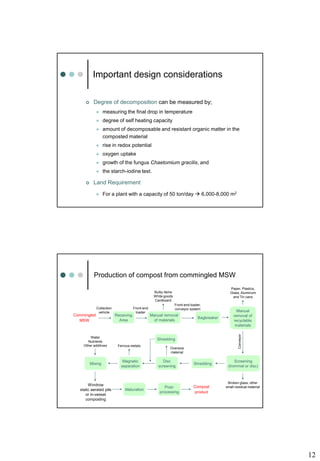

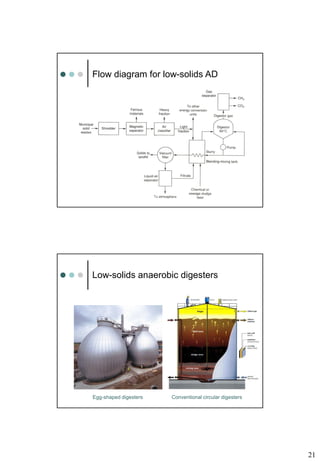

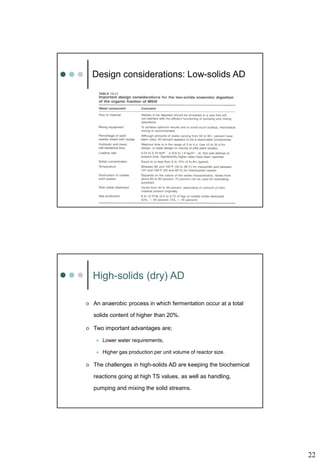

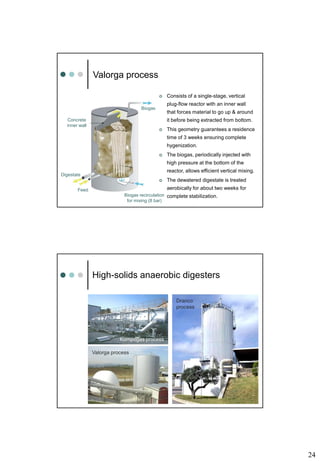

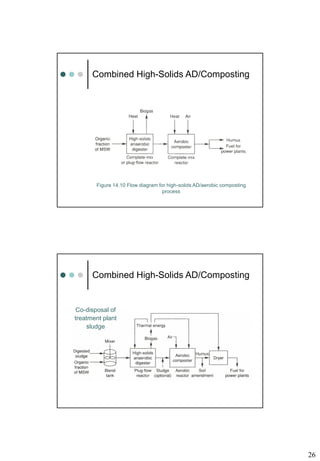

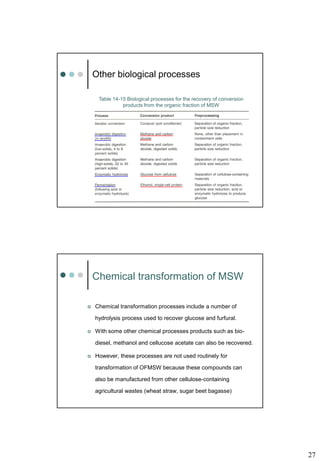

The document discusses biological and chemical conversion technologies for municipal solid waste (MSW), emphasizing biological conversion methods such as aerobic composting and anaerobic digestion (AD). It describes the processes, objectives, techniques, and important design considerations of composting, including steps like pre-processing, decomposition, and final product preparation. Anaerobic digestion is also analyzed, highlighting its three stages, design considerations, and various methods like low-solids and high-solids AD to optimize biogas production.