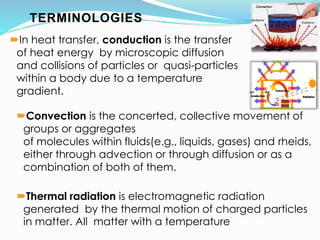

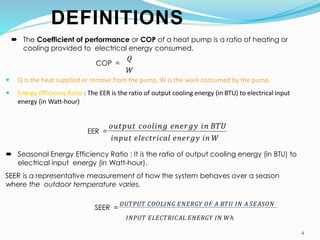

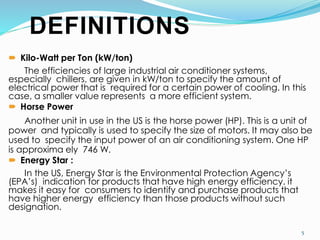

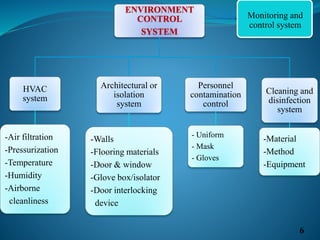

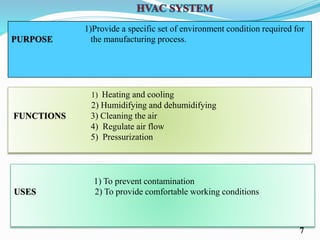

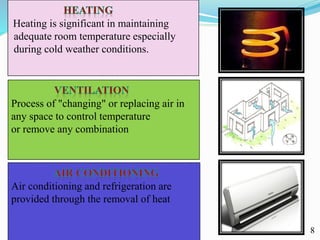

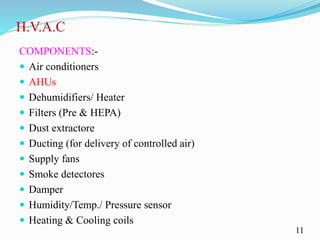

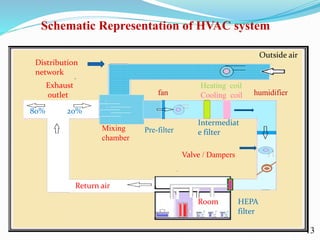

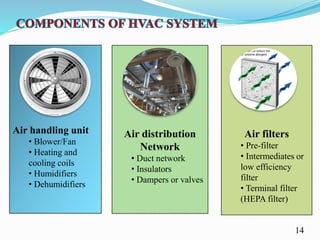

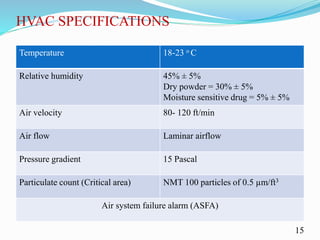

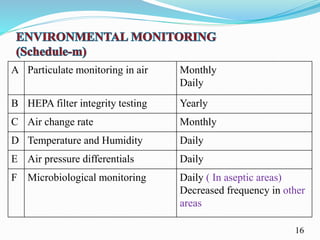

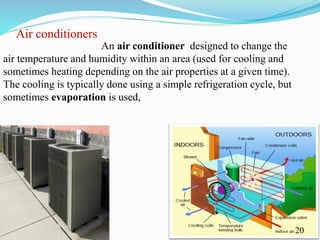

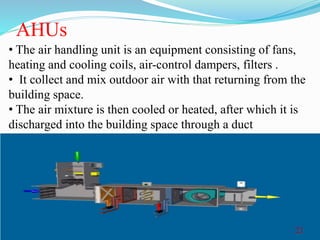

The document discusses key concepts related to HVAC systems. It defines thermodynamics, fluid mechanics, and heat transfer. It explains that thermodynamics deals with heat and its relation to energy and work. Fluid mechanics studies fluids and forces on them, divided into fluid statics, kinematics, and dynamics. Heat transfer involves mechanisms like conduction, convection, radiation, and phase changes. It also defines terms like COP, EER, SEER, kW/ton, and Energy Star ratings. Finally, it discusses HVAC system components like air conditioners, AHUs, filters, and ducting that control temperature, humidity, air quality, and airflow.