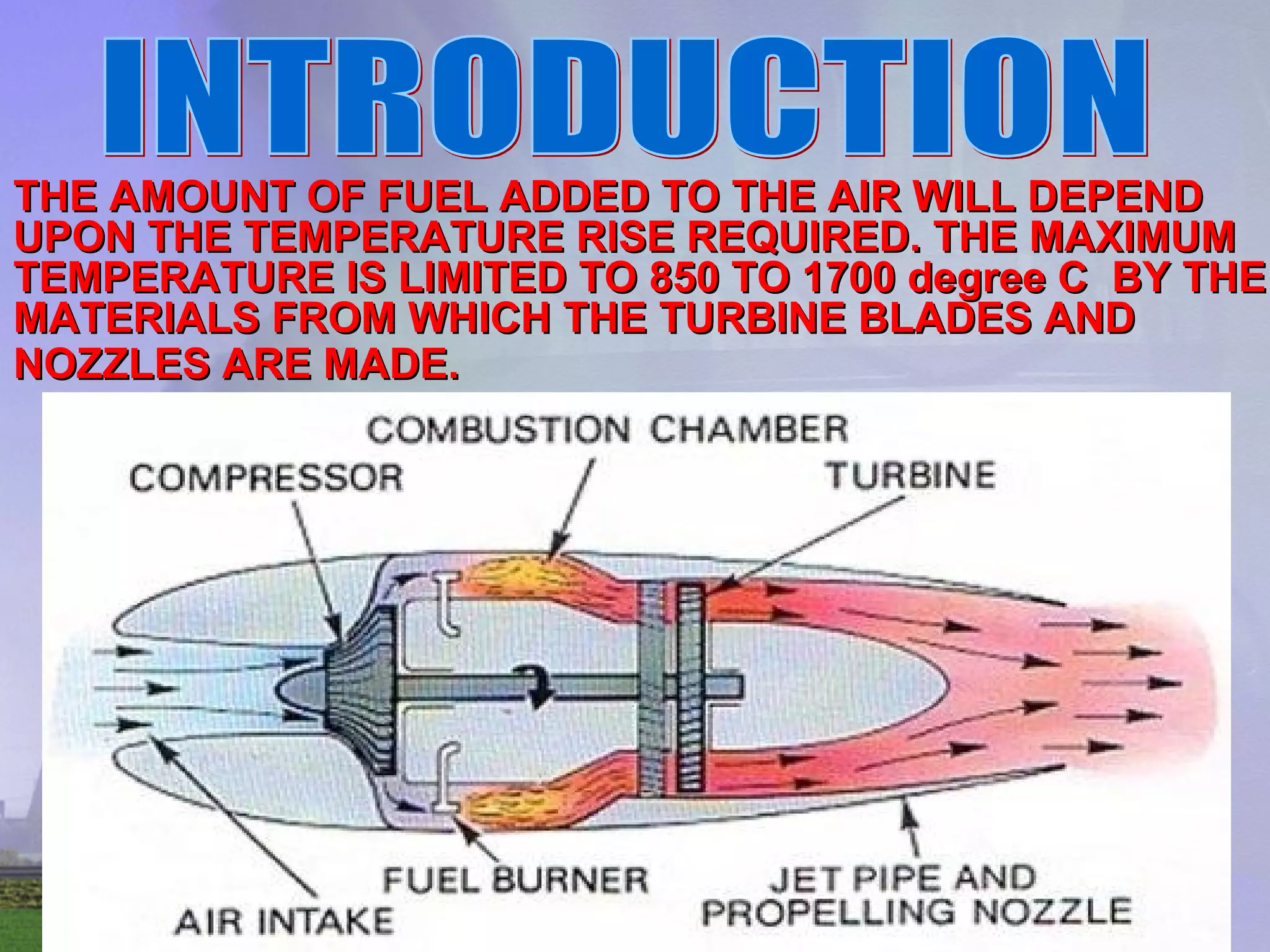

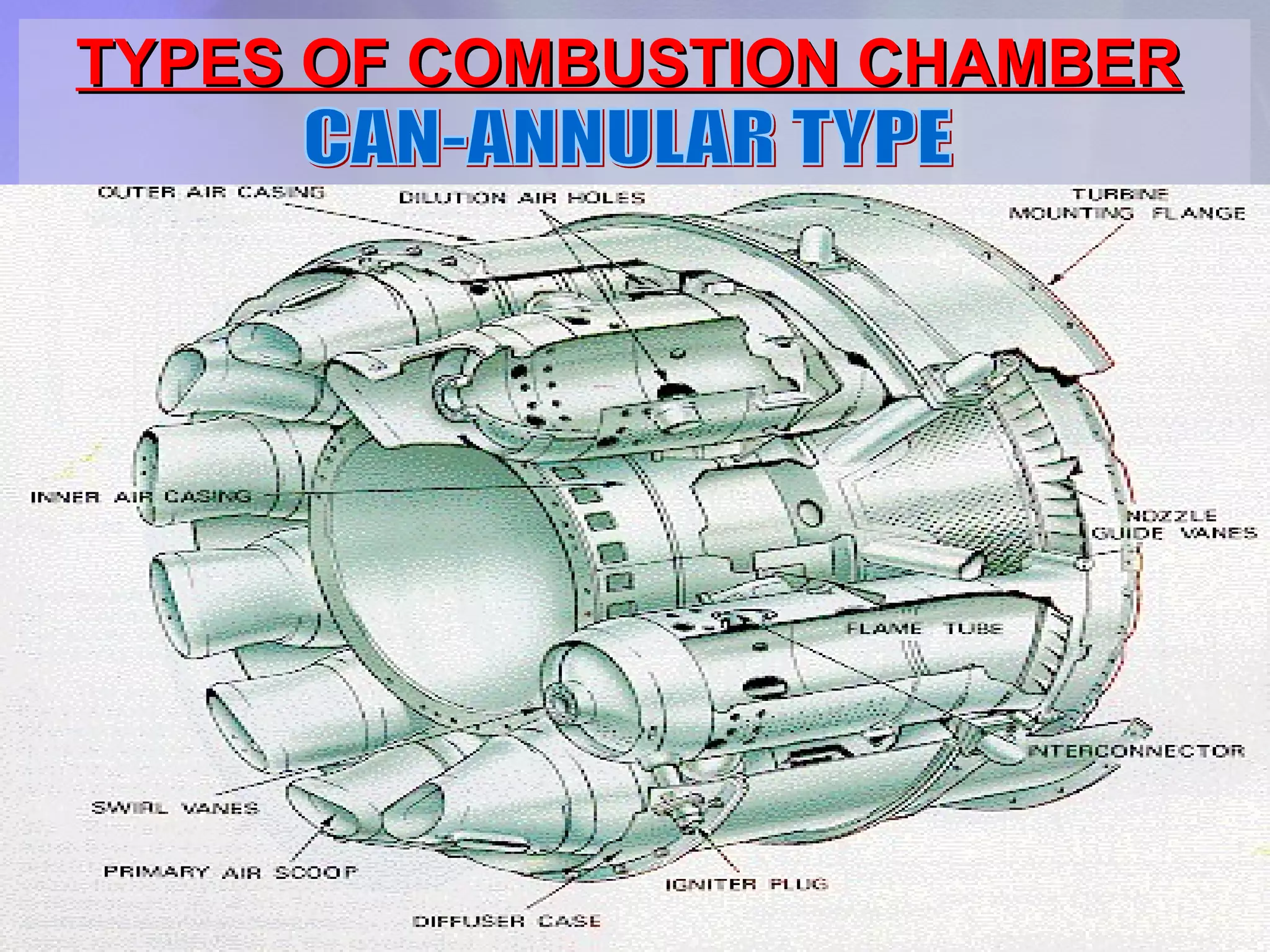

The document discusses the design and operational requirements of combustion chambers in jet engines. It notes that combustion chambers must burn large quantities of fuel and air at varying engine conditions while maintaining stable, efficient combustion and releasing heat in a way that expands and accelerates the air for the turbine. They accomplish this through designs that create recirculation zones for the flame, meter air distribution, and use most air for cooling rather than combustion to control temperatures before the turbine.