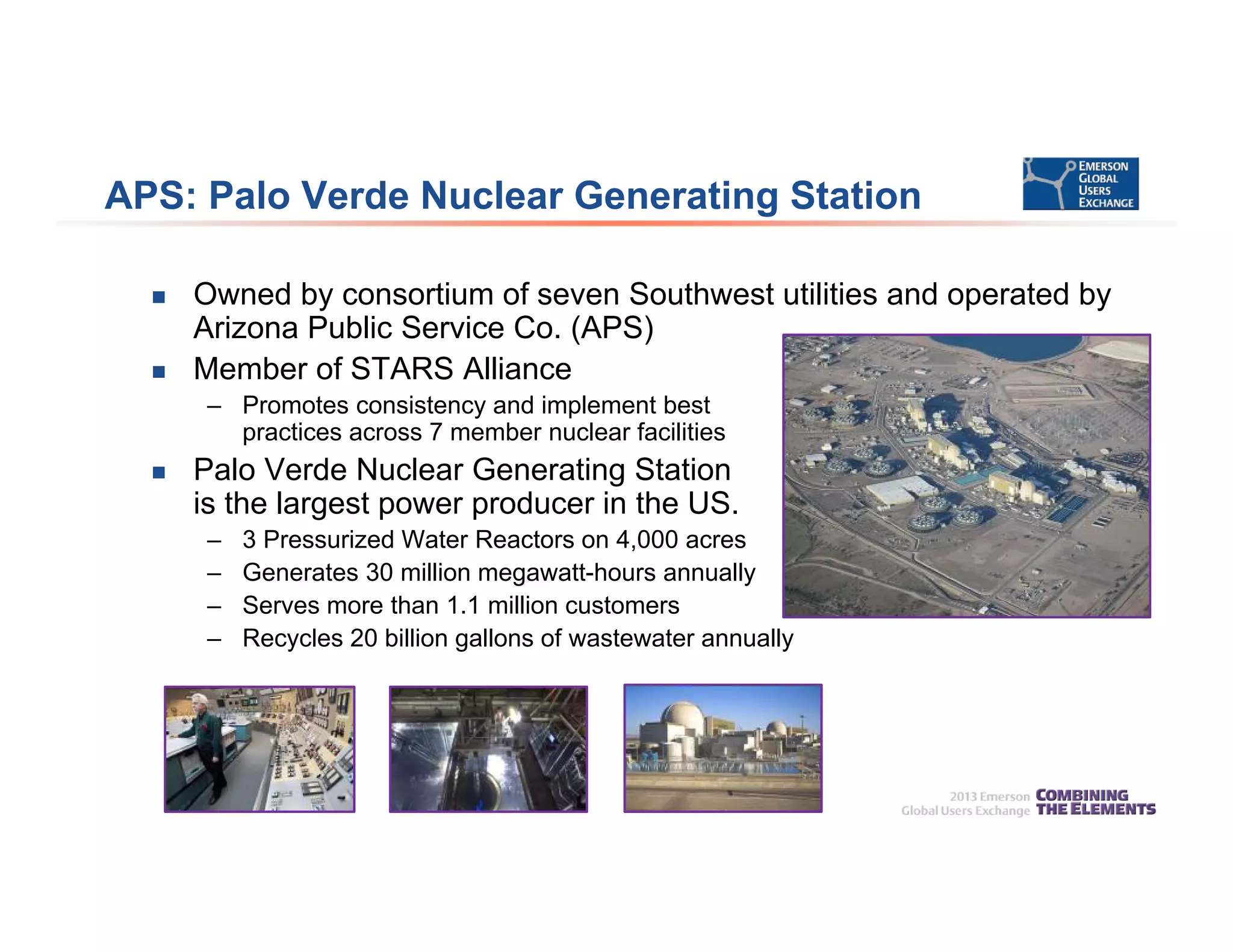

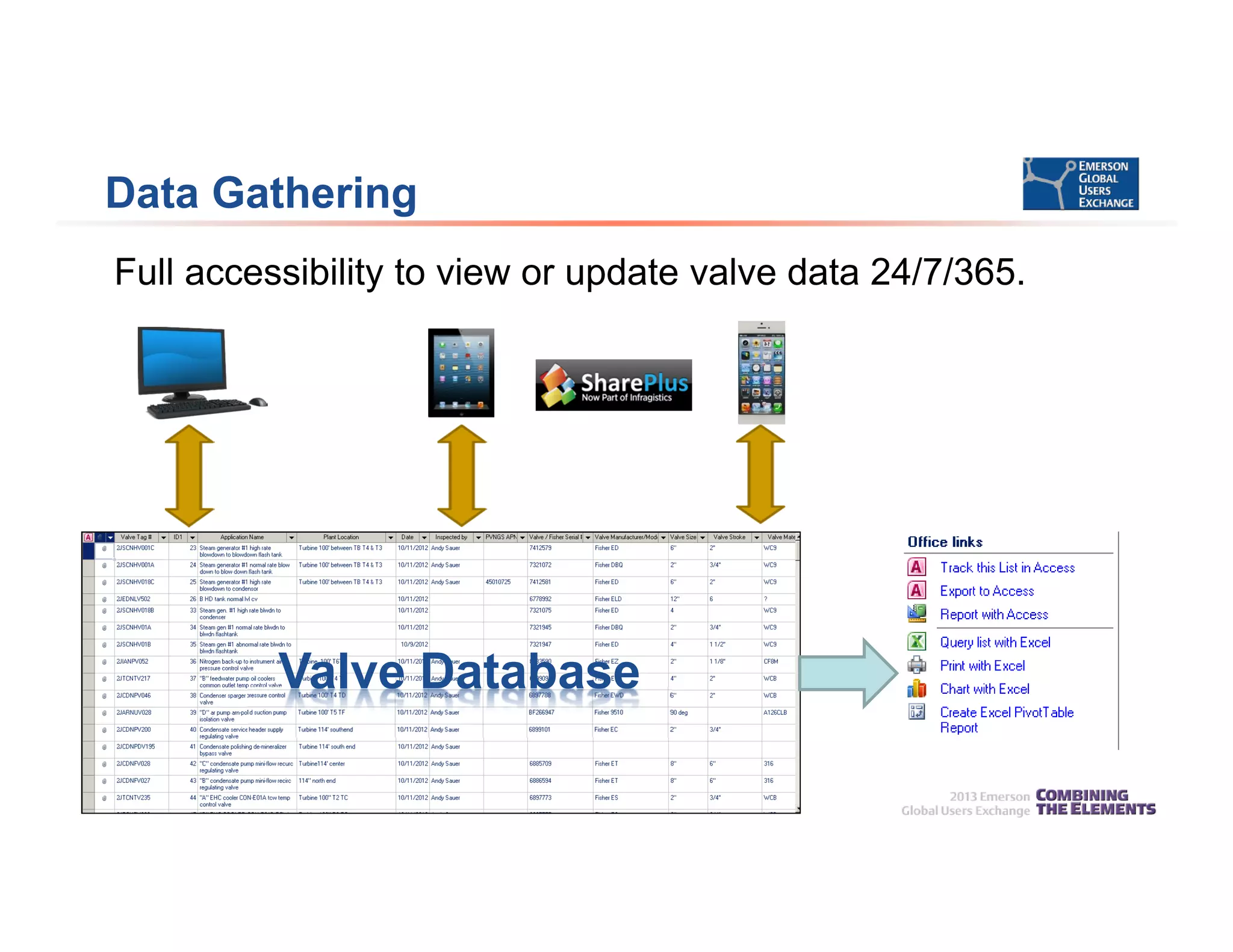

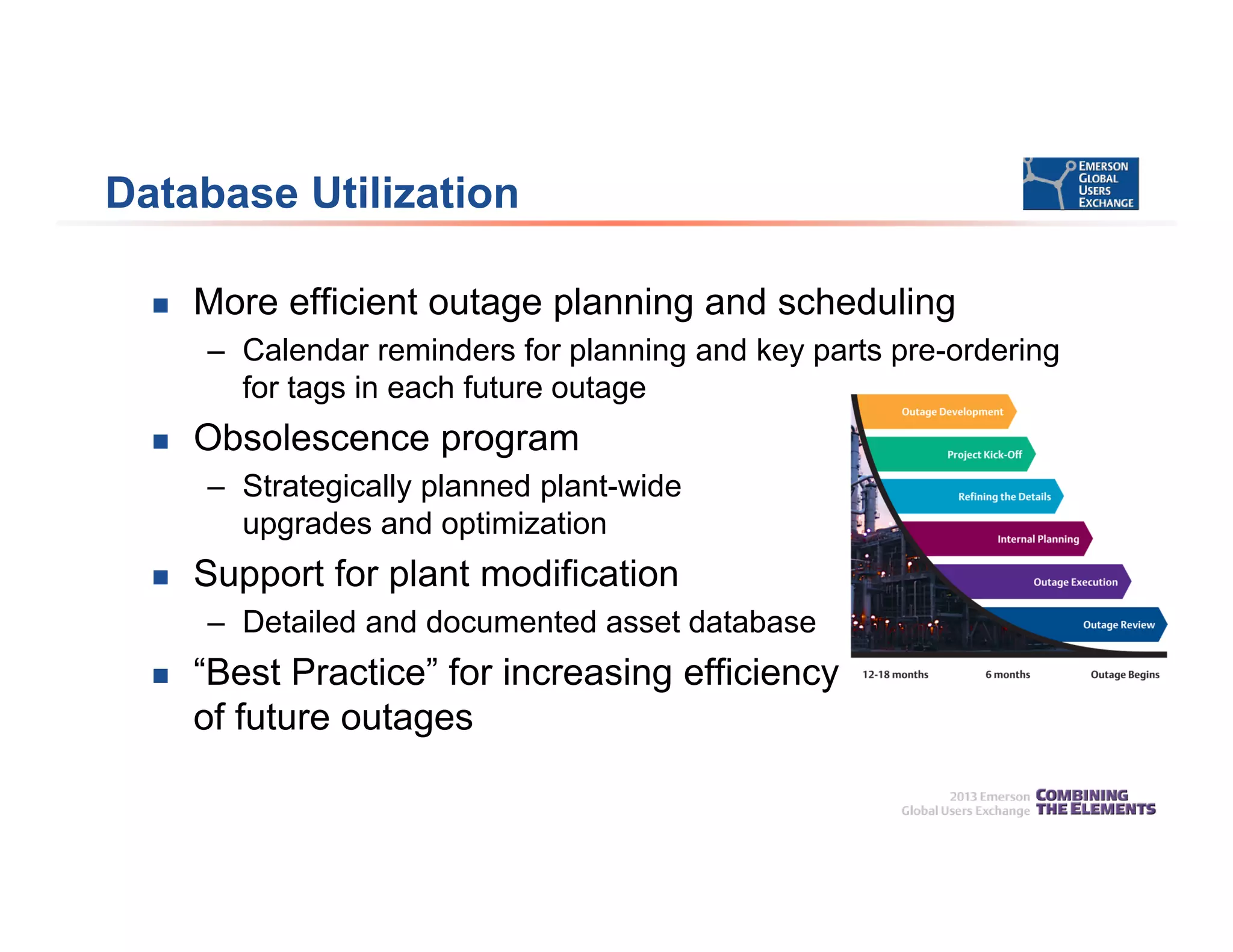

The document summarizes a presentation about a proactive asset management survey conducted by Caltrol and Emerson at the Palo Verde Nuclear Generating Station. The survey created a comprehensive database of process control assets to improve inventory management, outage planning, and identification of obsolete equipment. It addressed challenges like inconsistent asset data and extensive lead times. Using iPads and custom software, the survey gathered detailed asset information. The database allows more efficient outage scheduling, strategic replacement of obsolete products, and collaboration across plant teams. Expected benefits include reduced inventory costs, improved reliability, and savings of $4-6 million in inventory taxes.