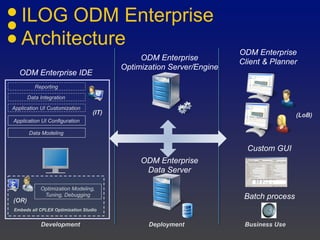

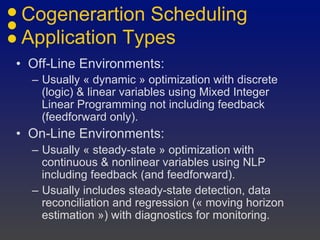

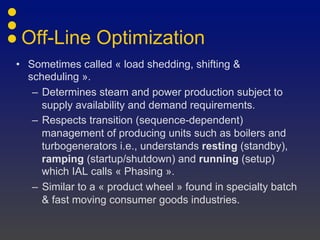

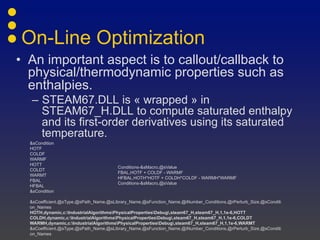

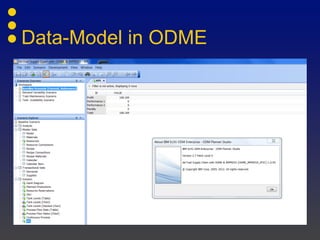

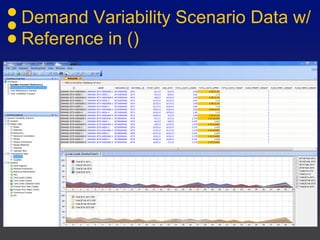

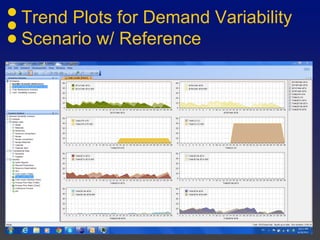

This document discusses using IBM's ODME and iMPress software for building cogeneration planning and scheduling applications. It provides an overview of ODME, iMPress, and how they can be implemented together. Key benefits include fitting business models/processes, sophisticated optimization, quick adaptation, and scenario analysis. A proof-of-concept is proposed to select a plant type, integrate data sources, solve models, and tune models for accuracy and tractability.