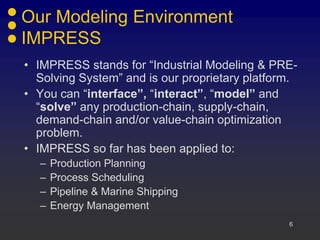

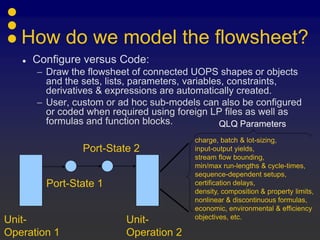

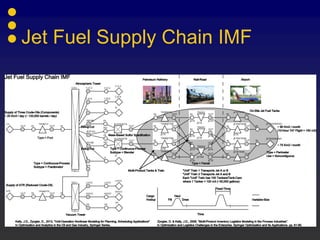

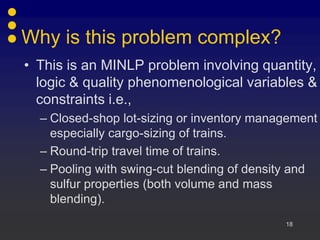

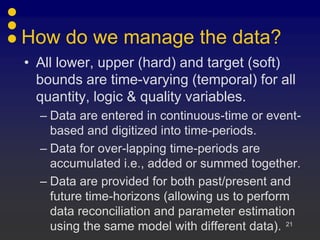

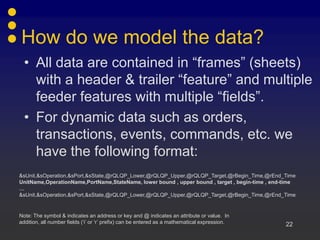

The document describes a jet fuel supply chain optimization problem modeled using IMPRESS, an industrial modeling and presolving system developed by Industrial Algorithms LLC. Key aspects include:

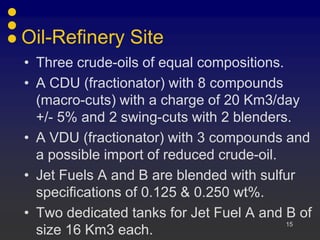

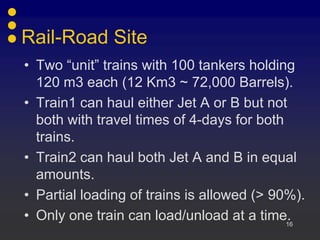

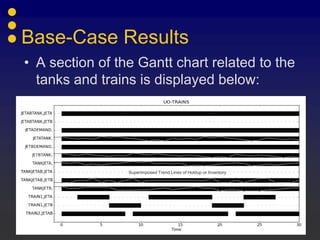

- The supply chain involves an oil refinery, rail transport, and an airport with complex logistical constraints around product blending, cargo loading, and demand variability.

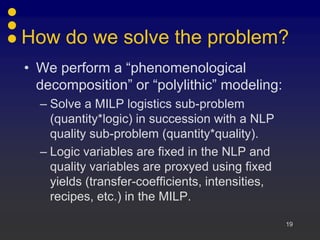

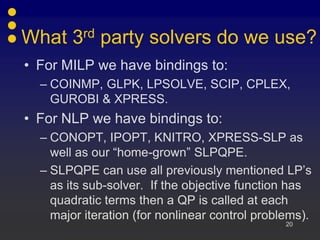

- IMPRESS uses a "phenomenological decomposition" approach to decompose the mixed-integer nonlinear problem into separate logistics and quality subproblems.

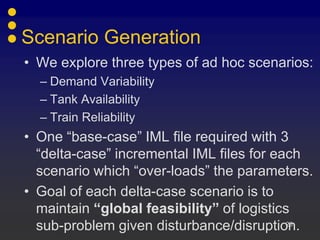

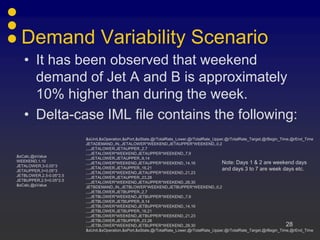

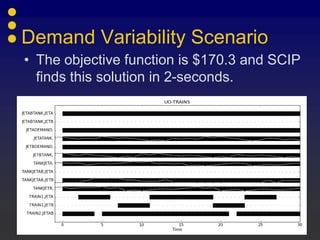

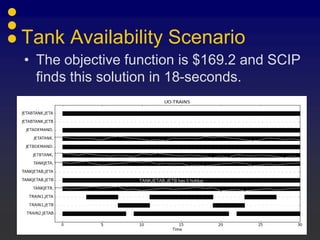

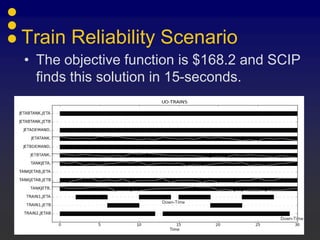

- Several scenarios are explored including demand variability, tank availability changes, and train reliability issues.

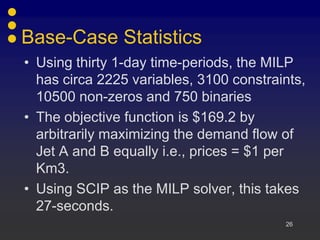

- The base case involves over 2,000 variables, 3,000 constraints, and takes 27 seconds to solve. Scenario