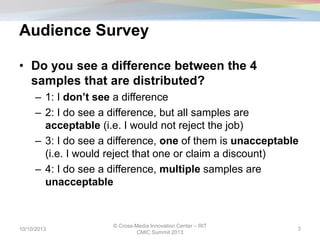

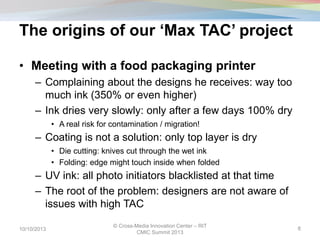

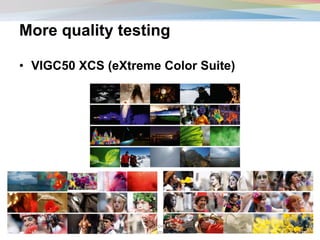

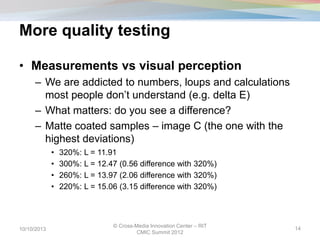

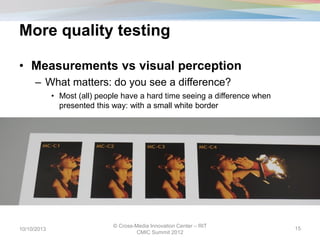

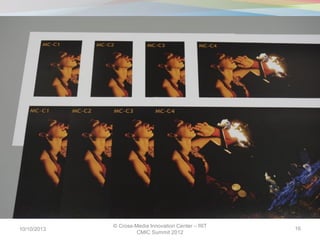

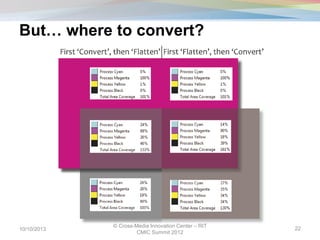

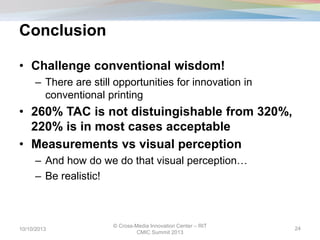

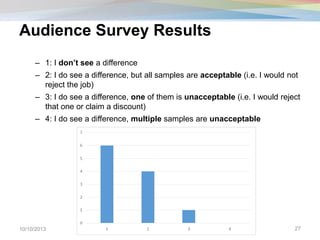

The document discusses challenges in food packaging printing, particularly regarding ink issues such as migration and drying times, and emphasizes the need for education among designers about these problems. It presents findings from a study about visual perception of print quality, revealing that reductions in total area coverage (tac) do not significantly affect print quality as perceived by experienced printers. The conclusion advocates for a holistic approach to printing that combines proper education and adherence to best practices to enhance quality and efficiency in the production process.