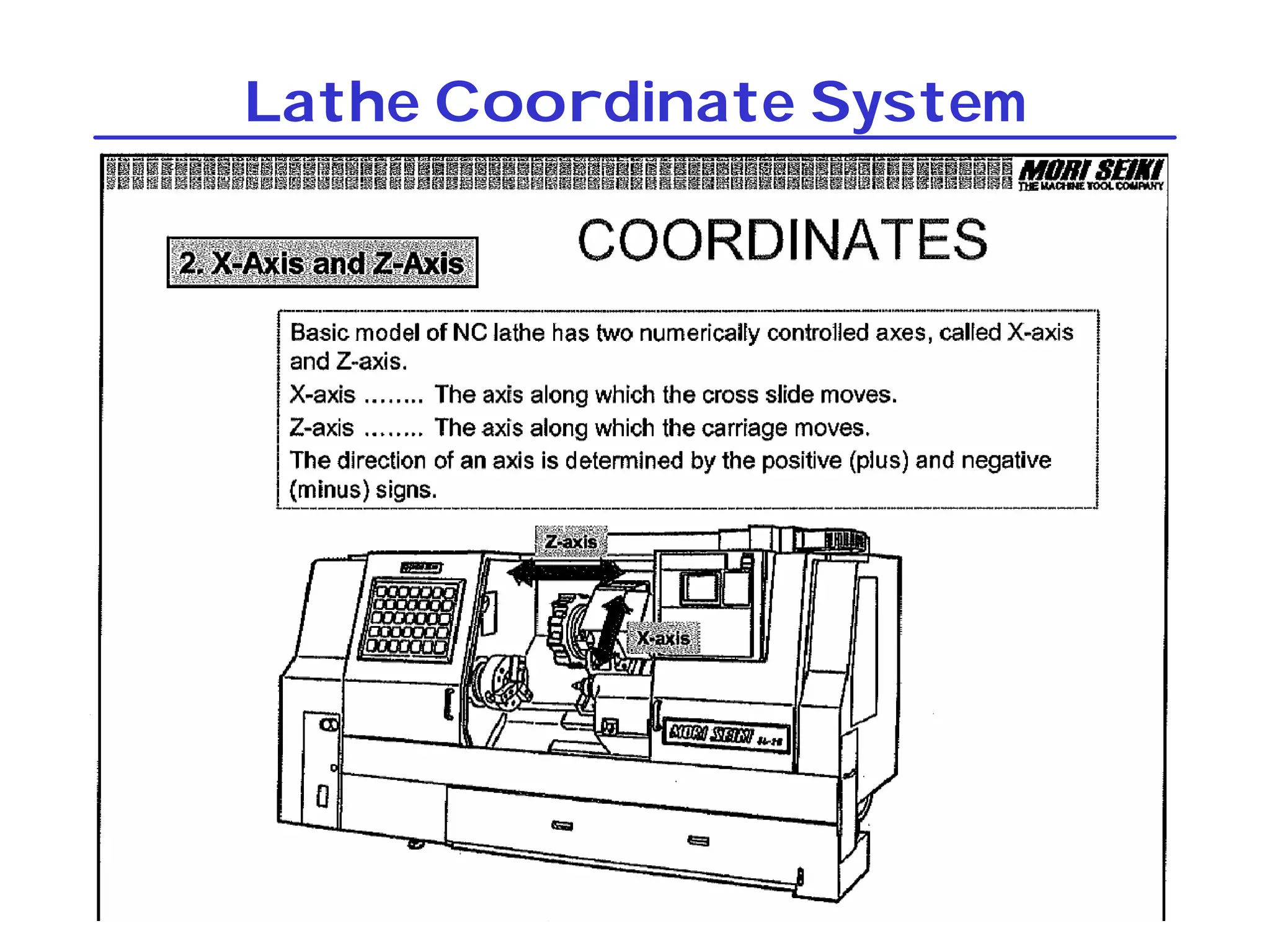

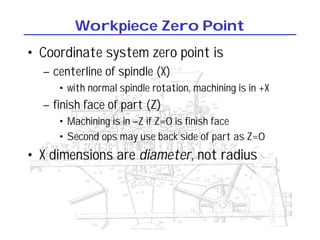

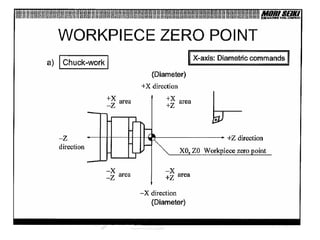

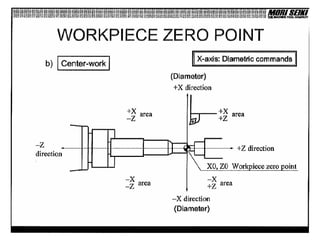

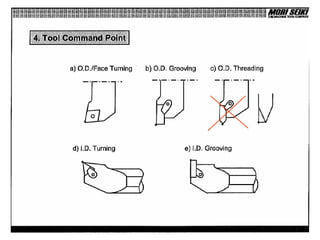

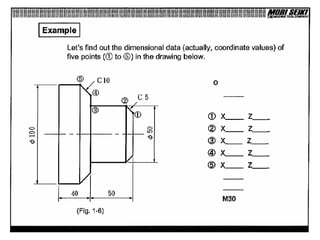

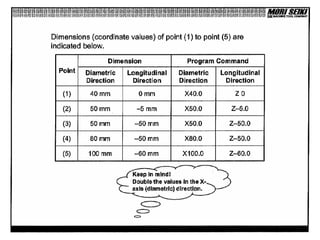

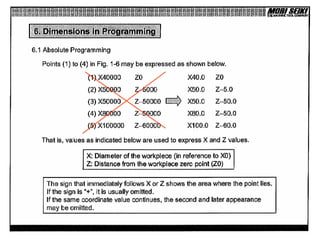

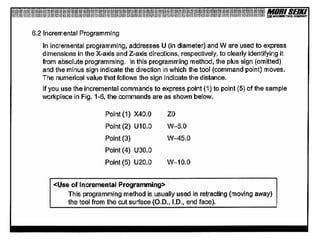

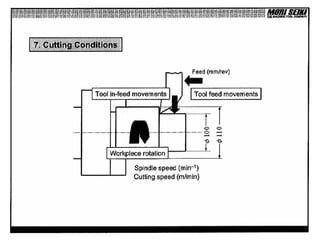

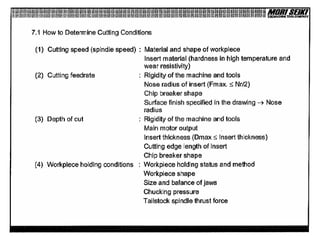

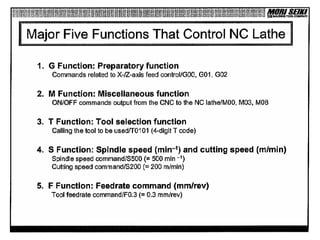

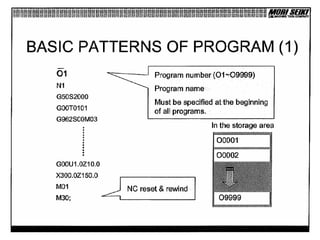

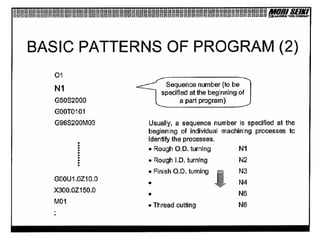

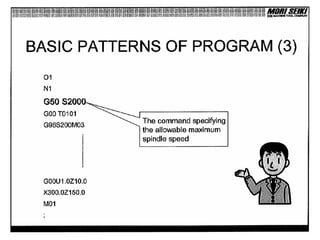

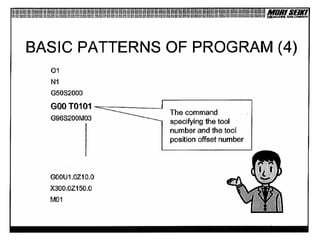

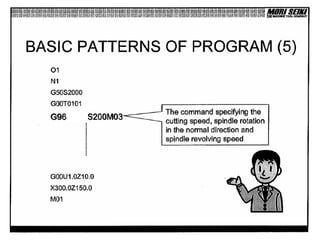

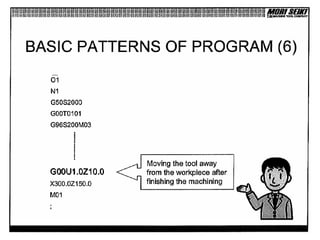

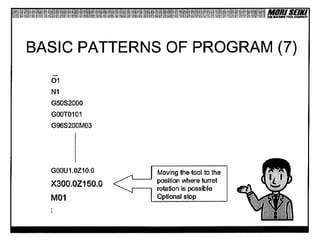

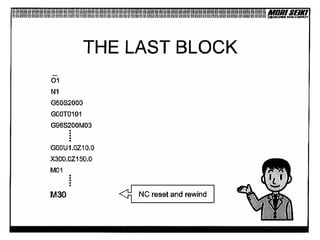

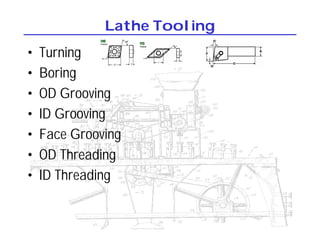

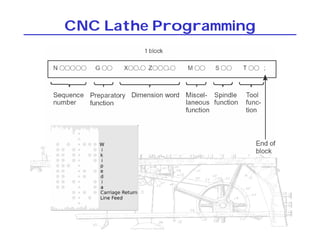

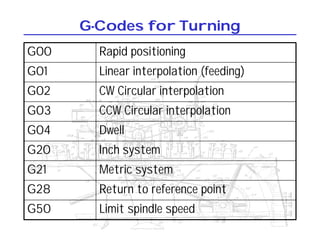

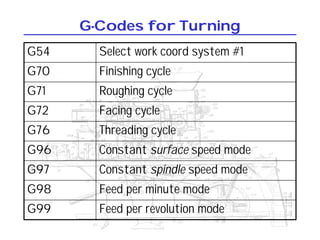

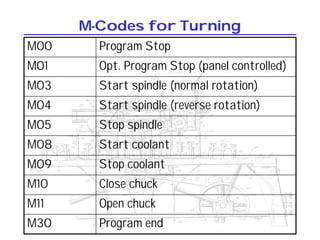

The document discusses the coordinate system and tooling used on lathe machines. It describes the zero point, dimensions, and typical tooling like turning, boring, grooving, and threading tools. It also lists the common G-codes and M-codes used in CNC lathe programming to control functions like spindle speed, feed rate, coordinate systems, and cycles for operations like facing, roughing and finishing.