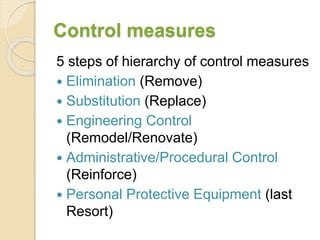

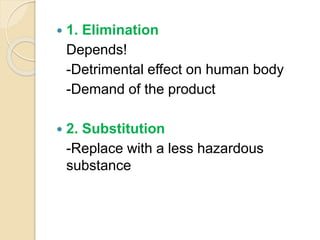

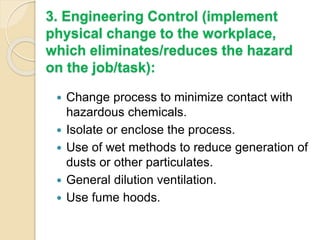

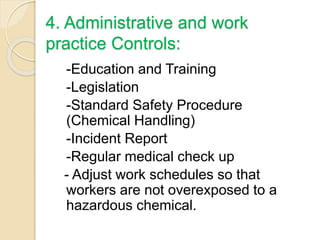

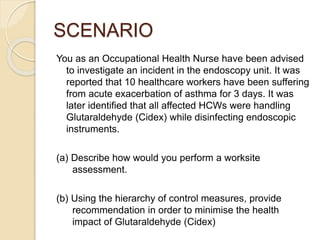

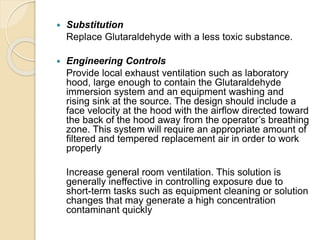

The document outlines the hierarchy of control measures to minimize workplace hazards, including elimination, substitution, engineering controls, administrative controls, and personal protective equipment. It then provides a scenario where healthcare workers are experiencing asthma from exposure to glutaraldehyde used to disinfect endoscopy instruments, and asks how a worksite assessment would be conducted and what control measures would be recommended.