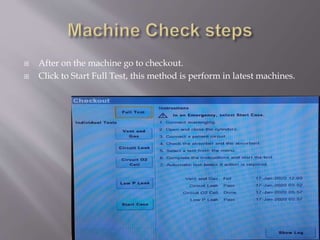

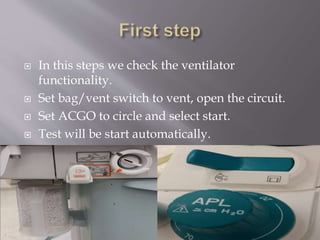

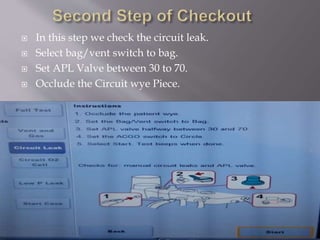

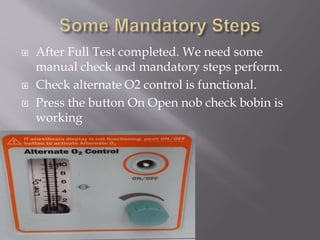

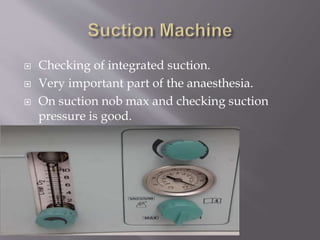

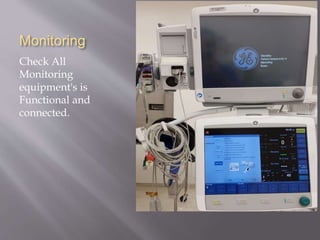

The document outlines the essential procedures and checks an anaesthesia technician must perform on the anaesthesia machine to ensure patient safety. Key steps include daily functionality tests, circuit leak tests, and verifying the operation of various components like the power supply and gas connections. Additionally, it emphasizes the importance of checking cylinder pressures and monitoring equipment to maintain safe anaesthesia practices.