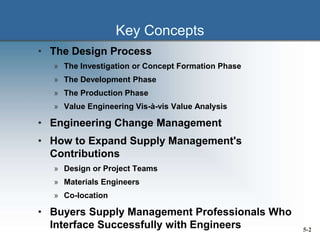

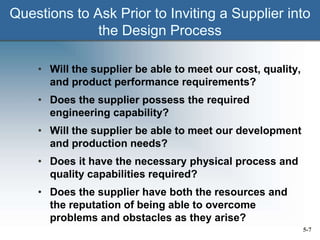

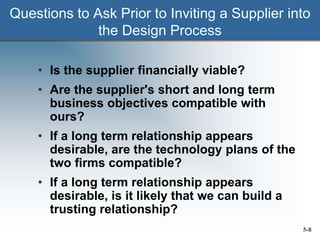

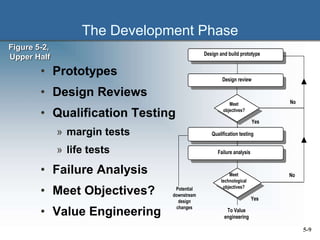

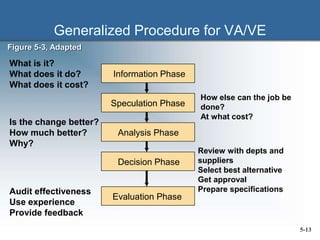

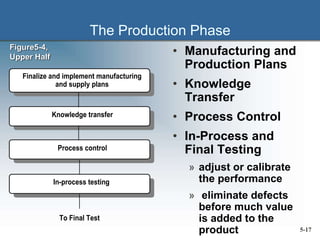

The document outlines the new product development process, highlighting key phases such as investigation, development, and production. It emphasizes the importance of early supplier involvement, value engineering, and effective collaboration between supply management and engineering professionals. By integrating supply management into the design stage, firms can significantly reduce costs and enhance product quality.