Okay, here are the steps to calculate the anchorage lengths:a) Straight bars:- Design stress in bar (σsd) = 100 MPa - Bar diameter (φ) = 16 mm- Bond stress (fbd) for C25/30 = 2.25 x 1 x 1 x 3 = 6.75 MPa (Table NA.2)- Required anchorage length (lb,rqd) = (φ/4) x (σsd/fbd) = (16/4) x (100/6.75) = 588 mm- Minimum anchorage length (lb,min) = max(0.3 x lb,rqd, 10φ

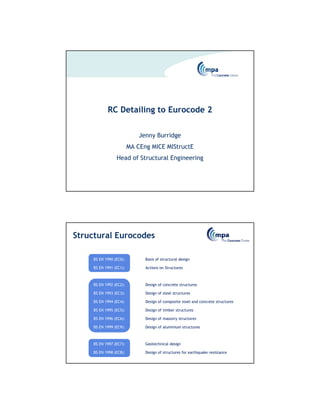

- 1. RC Detailing to Eurocode 2 Jenny Burridge MA CEng MICE MIStructE Head of Structural Engineering BS EN 1990 (EC0): Basis of structural design BS EN 1991 (EC1): Actions on Structures BS EN 1992 (EC2): Design of concrete structures BS EN 1993 (EC3): Design of steel structures BS EN 1994 (EC4): Design of composite steel and concrete structures BS EN 1995 (EC5): Design of timber structures BS EN 1996 (EC6): Design of masonry structures BS EN 1999 (EC9): Design of aluminium structures BS EN 1997 (EC7): Geotechnical design BS EN 1998 (EC8): Design of structures for earthquake resistance Structural Eurocodes

- 2. • General • Basis of design • Materials • Durability and cover to reinforcement • Structural analysis • Ultimate limit state • Serviceability limit state • Detailing of reinforcement and prestressing tendons – General • Detailing of member and particular rules • Additional rules for precast concrete elements and structures • Lightweight aggregated concrete structures • Plain and lightly reinforced concrete structures Eurocode 2 - contents A. (Informative) Modification of partial factors for materials B. (Informative) Creep and shrinkage strain C. (Normative) Reinforcement properties D. (Informative) Detailed calculation method for prestressing steel relaxation losses E. (Informative) Indicative Strength Classes for durability F. (Informative) Reinforcement expressions for in-plane stress conditions G. (Informative) Soil structure interaction H. (Informative) Global second order effects in structures I. (Informative) Analysis of flat slabs and shear walls J. (Informative) Examples of regions with discontinuity in geometry or action (Detailing rules for particular situations) Eurocode 2 - Annexes EC2 Annex J - replaced by Annex B in PD 6687

- 3. BS EN 1992 Design of concrete structures Part 1-1: General & buildings Part 1-2: Fire design Part 2: Bridges Part 3: Liquid retaining Standards BS EN 13670 Execution of Structures BS 4449 Reinforcing Steels BS EN 10080 Reinforcing SteelsBS 8500 Specifying Concrete BS EN 206-1 Specifying Concrete NSCS BS 8666 Reinforcement Scheduling National Annex PD 6687-1 (Parts 1 & 3) PD 6687-2 ( Part 2) N.A. Specification – NSCS, Finishes NSCS Guidance: 1 Basic 2 Ordinary 3 Plain 4 Special –Visual Concrete

- 4. Labour and Material (Peri) 18% 24% 58% Rationalisation of Reinforcement Optimum cost depends on: • Material cost • Labour • Plant • Preliminaries • Finance Team decision required

- 6. EC2 does not cover the use of plain or mild steel reinforcement Principles and Rules are given for deformed bars, decoiled rods, welded fabric and lattice girders. EN 10080 provides the performance characteristics and testing methods but does not specify the material properties. These are given in Annex C of EC2 Reinforcement Product form Bars and de-coiled rods Wire Fabrics Class A B C A B C Characteristic yield strength fyk or f0,2k (MPa) 400 to 600 k = (ft/fy)k ≥1,05 ≥1,08 ≥1,15 <1,35 ≥1,05 ≥1,08 ≥1,15 <1,35 Characteristic strain at maximum force, εεεεuk (%) ≥2,5 ≥5,0 ≥7,5 ≥2,5 ≥5,0 ≥7,5 Fatigue stress range (N = 2 x 106 ) (MPa) with an upper limit of 0.6fyk 150 100 cold worked seismichot rolled The UK has chosen a maximum value of characteristic yield strength, fyk, = 600 MPa, but 500 MPa is the value assumed in BS 4449 and 4483 for normal supply. Properties of reinforcement (Annex C)

- 7. Extract BS 8666 UK CARES (Certification - Product & Companies) 1. Reinforcing bar and coil 2. Reinforcing fabric 3. Steel wire for direct use of for further processing 4. Cut and bent reinforcement 5. Welding and prefabrication of reinforcing steel www.ukcares.co.uk www.uk-bar.org

- 8. www.ukcares.co.uk www.uk-bar.org A B C Coil up to 16mm (2.5T) Bar – 12,14,15 and 18m Cut and bent – approx £550 to £650/T Reinforcement supply

- 10. High Medium Low Potential Risk factor Smaller diameter bars cause less of a problem as they can often be produced on an automatic link bending machine. Larger diameter bars have to be produced on a manual power bender with the potential to trap the operator’s fingers. Try to avoid/minimise the use of shapes which cause a scissor action, especially with larger diameter bars. Boot Link. Greater risk than shape code 51 as the bars have to cross over twice to achieve the shape. Health and safety risk becomes higher with larger diameter bar. Also the risk increases with small dimensions. See Note SN2. When bent on an automatic link bender with small diameter bars the risk is relatively low. When bending on a manual bender the risk is higher, especially with larger diameters. 64 See Note SN2. Great care should be taken when bending this shape. If the operator has concerns when producing this shape he should consult his supervisor. This shape is designed for producing small to medium sized links in small diameter bar. Do not detail this shape in large diameter bar, try to use an alternative (eg. 2 no. shape code 13’s facing each other to create a shape code 33). See Note SN2. Sausage Link. Health and safety risk is high with larger diameter bar. Also the risk increases with small dimensions. When bent on an automatic link bender with small diameter bars the risk is relatively low. When bending on a manual bender the risk is high, especially with larger diameters and non standard formers. 33 FabricatorDesignerCommentDetailSC High Risk 33,51,56,63,64 & 99? Health & Safety Minimum Bending & projections Minimum Bends 6mm - 16mm = 2x Dia Internal 20mm - 50mm = 3.5x Dia Internal Minimum of 4 x dia between bends End Projection = 5 x Dia from end of bend Bending BS8666, Table 2

- 11. Tolerances (not in EC2—BS8666) For bars: Bar diameter For post-tensioned tendons: Circular ducts: Duct diameter Rectangular ducts: The greater of: the smaller dimension or half the greater dimension For pre-tensioned tendons: 1.5 x diameter of strand or wire 2.5 x diameter of indented wire Minimum Cover for Bond

- 12. a Axis Distance Reinforcement cover Axis distance, a, to centre of bar a = c + φφφφm/2 + φφφφl Scope: Part 1-2 Structural fire design gives several methods for fire engineering Tabulated data for various elements is given in section 5 Structural Fire Design BS EN 1992-1-2 ∆∆∆∆cdev: Allowance for deviation = 10mm A reduction in ∆∆∆∆cdev may be permitted: • for a quality assurance system, which includes measuring concrete cover, 10 mm ≥≥≥≥ ∆∆∆∆cdev ≥≥≥≥ 5 mm • where very accurate measurements are taken and non conforming members are rejected (eg precast elements) 10 mm ≥≥≥≥ ∆∆∆∆cdev ≥≥≥≥ 0 mm Allowance in Design for Deviation

- 13. Nominal cover, cnom Minimum cover, cmin cmin = max {cmin,b; cmin,dur ; 10 mm} Axis distance, a Fire protection Allowance for deviation, ∆cdev Nominal Cover Lead-in times should be 4 weeks for rebar Express reinforcement (and therefore expensive) 1 – 7 days The more complicated the scheduling the longer for bending Procurement

- 14. Practicalities 12m maximum length H20 to H40 (12m H40 = 18 stone/ 118Kg) Health & safety 9m maximum length H16 & H12 6m maximum length H10 & H8 Transport Fixing Standard Detailing Control of Cracking In Eurocode 2 cracking is controlled in the following ways: • Minimum areas of reinforcement cl 7.3.2 & Equ 7.1 As,minσs = kckfct,effAct this is the same as • Crack width limits (Cl. 7.3.1 and National Annex). These limits can be met by either: – direct calculation (Cl. 7.3.4) – crack width is Wk – Used for liquid retaining structures – ‘deemed to satisfy’ rules (Cl. 7.3.3) Note: slabs ≤ 200mm depth are OK if As,min is provided. EC2: Cl. 7.3

- 15. Minimum Reinforcement Area The minimum area of reinforcement for slabs (and beams) is given by: db0013.0 f dbf26.0 A t yk tctm min,s ≥≥ EC2: Cl. 9.2.1.1, Eq 9.1N Crack Control Without Direct Calculation Provide minimum reinforcement. Crack control may be achieved in two ways: • limiting the maximum bar diameter using Table 7.2N • limiting the maximum bar spacing using Table 7.3N EC2: Cl. 7.3.3 Note: For cracking due to restraint use only max bar size

- 16. • Clear horizontal and vertical distance ≥ φ, (dg +5mm) or 20mm • For separate horizontal layers the bars in each layer should be located vertically above each other. There should be room to allow access for vibrators and good compaction of concrete. Spacing of bars EC2: Cl. 8.2 The design value of the ultimate bond stress, fbd = 2.25 η1η2fctd where fctd should be limited to C60/75 η1 =1 for ‘good’ and 0.7 for ‘poor’ bond conditions η2 = 1 for φ ≤ 32, otherwise (132- φ)/100 a) 45º ≤≤≤≤ αααα ≤≤≤≤ 90º c) h > 250 mm h Direction of concreting ≥ 300 h Direction of concreting b) h ≤≤≤≤ 250 mm d) h > 600 mm unhatched zone – ‘good’ bond conditions hatched zone - ‘poor’ bond conditions α Direction of concreting 250 Direction of concreting Ultimate bond stress EC2: Cl. 8.4.2

- 17. lb,rqd = (φφφφ / 4) (σσσσsd / fbd) where σsd is the design stress of the bar at the position from where the anchorage is measured. Basic required anchorage length EC2: Cl. 8.4.3 • For bent bars lb,rqd should be measured along the centreline of the bar lbd = α1 α2 α3 α4 α5 lb,rqd ≥≥≥≥ lb,min However: (α2 α3 α5) ≥≥≥≥ 0.7 lb,min > max(0.3lb,rqd ; 10φφφφ, 100mm) Design Anchorage Length, lbd EC2: Cl. 8.4.4

- 18. Alpha values EC2: Table 8.2 Table 8.2 - Cd & K factors EC2: Figure 8.3 EC2: Figure 8.4

- 19. Anchorage of links EC2: Cl. 8.5 l0 = α1 α2 α3 α5 α6 lb,rqd ≥≥≥≥ l0,min α6 = (ρ1/25)0,5 but between 1.0 and 1.5 where ρ1 is the % of reinforcement lapped within 0.65l0 from the centre of the lap Percentage of lapped bars relative to the total cross- section area < 25% 33% 50% >50% α6 1 1.15 1.4 1.5 Note: Intermediate values may be determined by interpolation. α1 α2 α3 α5 are as defined for anchorage length l0,min ≥ max{0.3 α6 lb,rqd; 15φ; 200} Design Lap Length, l0 (8.7.3) EC2: Cl. 8.7.3

- 20. Worked example Anchorage and lap lengths Anchorage Worked Example Calculate the tension anchorage for an H16 bar in the bottom of a slab: a) Straight bars b) Other shape bars (Fig 8.1 b, c and d) Concrete strength class is C25/30 Nominal cover is 25mm

- 21. Bond stress, fbd fbd = 2.25 η1 η2 fctd EC2 Equ. 8.2 η1 = 1.0 ‘Good’ bond conditions η2 = 1.0 bar size ≤ 32 fctd = αct fctk,0,05/γc EC2 cl 3.1.6(2), Equ 3.16 αct = 1.0 γc = 1.5 fctk,0,05 = 0.7 x 0.3 fck 2/3 EC2 Table 3.1 = 0.21 x 252/3 = 1.8 MPa fctd = αct fctk,0,05/γc = 1.8/1.5 = 1.2 fbd = 2.25 x 1.2 = 2.7 MPa Basic anchorage length, lb,req lb.req = (Ø/4) ( σsd/fbd) EC2 Equ 8.3 Max stress in the bar, σsd = fyk/γs = 500/1.15 = 435MPa. lb.req = (Ø/4) ( 435/2.7) = 40.3 Ø For concrete class C25/30

- 22. Design anchorage length, lbd lbd = α1 α2 α3 α4 α5 lb.req ≥ lb,min lbd = α1 α2 α3 α4 α5 (40.3Ø) For concrete class C25/30 Alpha values EC2: Table 8.2 Concise: 11.4.2

- 23. Table 8.2 - Cd & K factors Concise: Figure 11.3EC2: Figure 8.3 EC2: Figure 8.4 Design anchorage length, lbd lbd = α1 α2 α3 α4 α5 lb.req ≥ lb,min lbd = α1 α2 α3 α4 α5 (40.3Ø) For concrete class C25/30 a) Tension anchorage – straight bar α1 = 1.0 α3 = 1.0 conservative value with K= 0 α4 = 1.0 N/A α5 = 1.0 conservative value α2 = 1.0 – 0.15 (cd – Ø)/Ø α2 = 1.0 – 0.15 (25 – 16)/16 = 0.916 lbd = 0.916 x 40.3Ø = 36.9Ø = 590mm

- 24. Design anchorage length, lbd lbd = α1 α2 α3 α4 α5 lb.req ≥ lb,min lbd = α1 α2 α3 α4 α5 (40.3Ø) For concrete class C25/30 b) Tension anchorage – Other shape bars α1 = 1.0 cd = 25 is ≤ 3 Ø = 3 x 16 = 48 α3 = 1.0 conservative value with K= 0 α4 = 1.0 N/A α5 = 1.0 conservative value α2 = 1.0 – 0.15 (cd – 3Ø)/Ø ≤ 1.0 α2 = 1.0 – 0.15 (25 – 48)/16 = 1.25 ≤ 1.0 lbd = 1.0 x 40.3Ø = 40.3Ø = 645mm Worked example - summary H16 Bars – Concrete class C25/30 – 25 Nominal cover Tension anchorage – straight bar lbd = 36.9Ø = 590mm Tension anchorage – Other shape bars lbd = 40.3Ø = 645mm lbd is measured along the centreline of the bar Compression anchorage (α1 = α2 = α3 = α4 = α5 = 1.0) lbd = 40.3Ø = 645mm Anchorage for ‘Poor’ bond conditions = ‘Good’/0.7 Lap length = anchorage length x α6

- 25. How to design concrete structures using Eurocode 2 Anchorage & lap lengths Arrangement of Laps EC2: Cl. 8.7.2, Fig 8.7 If more than one layer a maximum of 50% can be lapped

- 26. Arrangement of Laps EC2: Cl. 8.7.3, Fig 8.8 Anchorage of bars F Transverse Reinforcement There is transverse tension – reinforcement required

- 27. F/2 F/2 θ F tanθ F tanθ F F Lapping of bars Transverse Reinforcement There is transverse tension – reinforcement required • Where the diameter, φφφφ, of the lapped bars ≥ 20 mm, the transverse reinforcement should have a total area, ΣAst ≥ 1,0As of one spliced bar. It should be placed perpendicular to the direction of the lapped reinforcement and between that and the surface of the concrete. • If more than 50% of the reinforcement is lapped at one point and the distance between adjacent laps at a section is ≤ 10 φφφφ transverse bars should be formed by links or U bars anchored into the body of the section. • The transverse reinforcement provided as above should be positioned at the outer sections of the lap as shown below. l /30 ΣA /2st ΣA /2st l /30 FsFs ≤150 mm l0 Transverse Reinforcement at Laps Bars in tension EC2: Cl. 8.7.4, Fig 8.9 only if bar Ø ≥ 20mm or laps > 25%

- 28. • As,min = 0,26 (fctm/fyk)btd but ≥ 0,0013btd • As,max = 0,04 Ac • Section at supports should be designed for a hogging moment ≥ 0,25 max. span moment • Any design compression reinforcement (φ) should be held by transverse reinforcement with spacing ≤15 φ Beams EC2: Cl. 9.2 • Tension reinforcement in a flanged beam at supports should be spread over the effective width (see 5.3.2.1) Beams EC2: Cl. 9.2

- 29. Shear Design: Links Variable strut method allows a shallower strut angle – hence activating more links. As strut angle reduces concrete stress increases Angle = 45°V carried on 3 links Angle = 21.8° V carried on 6 links d V z x d x V θ z s EC2: Cl. 6.2.3 • Where av ≤ 2d the applied shear force, VEd, for a point load (eg, corbel, pile cap etc) may be reduced by a factor av/2d where 0.5 ≤ av ≤ 2d provided: dd av av − The longitudinal reinforcement is fully anchored at the support. − Only that shear reinforcement provided within the central 0.75av is included in the resistance. Short Shear Spans with Direct Strut Action EC2: Cl. 6.2.3 (8) Note: see PD6687-1:2010 Cl 2.14 for more information.

- 30. Shear reinforcement • Minimum shear reinforcement, ρw,min = (0,08√fck)/fyk • Maximum longitudinal spacing, sl,max = 0,75d (1 + cotα) • Maximum transverse spacing, st,max = 0,75d ≤ 600 mm EC2: Cl. 9.2.2 For vertical links sl,max = 0,75d Shear Design d V z x d x V θ z s EC2: Cl. 6.2.3

- 31. • For members without shear reinforcement this is satisfied with al = d al ∆Ftd al Envelope of (MEd /z +NEd) Acting tensile force Resisting tensile force lbd lbd lbd lbd lbd lbd lbd lbd ∆Ftd “Shift rule” Curtailment of reinforcement EC2: Cl. 9.2.1.3, Fig 9.2 • For members with shear reinforcement: al = 0.5 z Cot θ But it is always conservative to use al = 1.125d • lbd is required from the line of contact of the support. Simple support (indirect) Simple support (direct) • As bottom steel at support ≥ 0.25 As provided in the span • Transverse pressure may only be taken into account with a ‘direct’ support. Shear shift rule al Tensile Force Envelope Anchorage of Bottom Reinforcement at End Supports EC2: Cl. 9.2.1.4

- 32. Simplified Detailing Rules for Beams ≤ h /31 ≤ h /21 B A ≤ h /32 ≤ h /22 supporting beam with height h1 supported beam with height h2 (h1 ≥ h2) • The supporting reinforcement is in addition to that required for other reasons A B • The supporting links may be placed in a zone beyond the intersection of beams Supporting Reinforcement at ‘Indirect’ Supports Plan view EC2: Cl. 9.2.5

- 33. • Curtailment – as beams except for the “Shift” rule al = d may be used • Flexural Reinforcement – min and max areas as beam • Secondary transverse steel not less than 20% main reinforcement • Reinforcement at Free Edges Solid slabs EC2: Cl. 9.3 • Where partial fixity exists, not taken into account in design: Internal supports: As,top ≥ 0,25As for Mmax in adjacent span End supports: As,top ≥ 0,15As for Mmax in adjacent span • This top reinforcement should extend ≥ 0,2 adjacent span Solid slabs EC2: Cl. 9.3

- 34. Distribution of moments EC2: Table I.1 Particular rules for flat slabs • Arrangement of reinforcement should reflect behaviour under working conditions. • At internal columns 0.5At should be placed in a width = 0.25 × panel width. • At least two bottom bars should pass through internal columns in each orthogonal directions. Particular rules for flat slabs EC2: Cl. 9.4

- 35. • h ≤ 4b • φmin ≥ 12 • As,min = 0,10NEd/fyd but ≥ 0,002 Ac • As,max = 0.04 Ac (0,08Ac at laps) • Minimum number of bars in a circular column is 4. • Where direction of longitudinal bars changes more than 1:12 the spacing of transverse reinforcement should be calculated. Columns EC2: Cl. 9.5.2 • scl,tmax = min {20 φmin; b ; 400mm} ≤ 150mm ≤ 150mm scl,tmax • scl,tmax should be reduced by a factor 0,6: – in sections within h above or below a beam or slab – near lapped joints where φ > 14. A min of 3 bars is required in lap length scl,tmax = min {12 φmin; 0.6b ; 240mm} Columns EC2: Cl. 9.5.3

- 36. Walls • As,vmin = 0,002 Ac (half located at each face) • As,vmax = 0.04 Ac (0,08Ac at laps) • svmax = 3 × wall thickness or 400mm Vertical Reinforcement Horizontal Reinforcement • As,hmin = 0,25 Vert. Rein. or 0,001Ac • shmax = 400mm Transverse Reinforcement • Where total vert. rein. exceeds 0,02 Ac links required as for columns • Where main rein. placed closest to face of wall links are required (at least 4No. m2). [Not required for welded mesh or bars Ø ≤ 16mm with cover at least 2Ø.] Detailing Comparisons d or 150 mm from main bar9.2.2 (8): 0.75 d ≤ 600 mm 9.2.1.2 (3) or 15φ from main bar st,max 0.75d9.2.2 (6): 0.75 dsl,max 0.4 b s/0.87 fyv9.2.2 (5): (0.08 b s √fck)/fykAsw,min Links Table 3.28Table 7.3NSmax dg + 5 mm or φ8.2 (2): dg + 5 mm or φ or 20mmsmin Spacing of Main Bars 0.04 bh9.2.1.1 (3): 0.04 bdAs,max 0.002 bh--As,min Main Bars in Compression 0.04 bh9.2.1.1 (3): 0.04 bdAs,max 0.0013 bh9.2.1.1 (1): 0.26 fctm/fykbd ≥ 0.0013 bd As,min ValuesClause / ValuesMain Bars in Tension BS 8110EC2Beams

- 37. Detailing Comparisons places of maximum moment: main: 2h ≤ 250 mm secondary: 3h ≤ 400 mm 3d or 750 mmsecondary: 3.5h ≤ 450 mmSmax dg + 5 mm or φ8.2 (2): dg + 5 mm or φ or 20mm 9.3.1.1 (3): main 3h ≤ 400 mm smin Spacing of Bars 0.04 bh9.2.1.1 (3): 0.04 bdAs,max 0.002 bh9.3.1.1 (2): 0.2As for single way slabs As,min Secondary Transverse Bars 0.04 bh0.04 bdAs,max 0.0013 bh9.2.1.1 (1): 0.26 fctm/fykbd ≥ 0.0013 bd As,min ValuesClause / ValuesMain Bars in Tension BS 8110EC2Slabs Detailing Comparisons Columns 150 mm from main bar9.5.3 (6): 150 mm from main bar 12φ9.5.3 (3): min (12φmin; 0.6 b;240 mm)Scl,tmax 0.25φ or 6 mm9.5.3 (1) 0.25φ or 6 mmMin size Links 0.06 bh9.5.2 (3): 0.04 bhAs,max 0.004 bh9.5.2 (2): 0.10NEd/fyk ≤ 0.002bhAs,min Main Bars in Compression 1.5d9.4.3 (1): within 1st control perim.: 1.5d outside 1st control perim.: 2d St 0.75d9.4.3 (1): 0.75dSr Spacing of Links Total = 0.4ud/0.87fyv9.4.3 (2): Link leg = 0.053 sr st √(fck)/fyk Asw,min ValuesClause / ValuesLinks BS 8110EC2Punching Shear

- 39. Keep up to date Download: • Column charts • Derivations • Worked examples • How to… guides • & more www.eurocode2.info