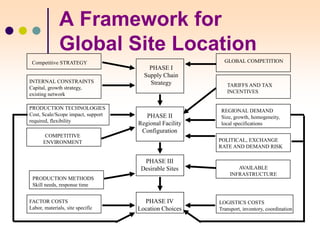

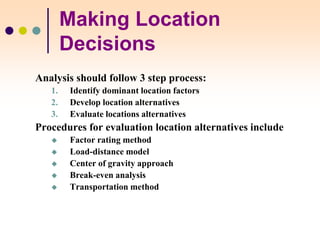

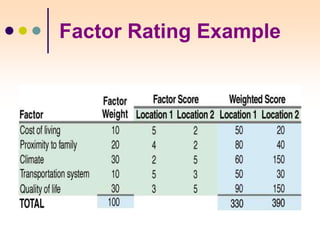

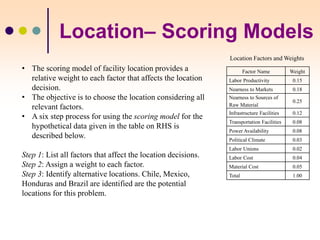

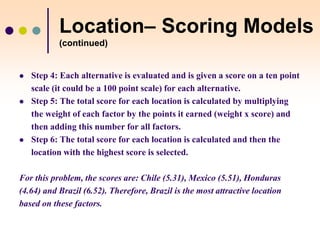

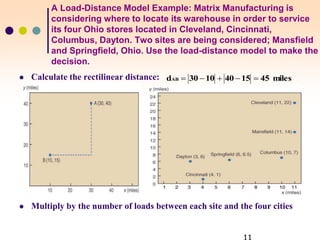

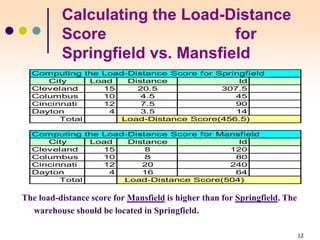

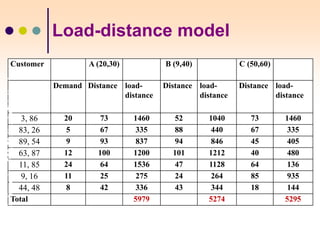

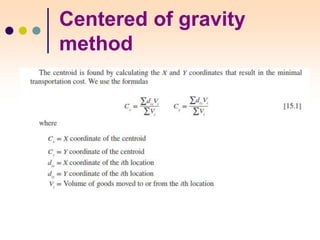

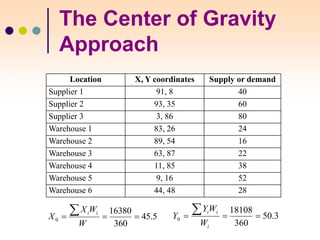

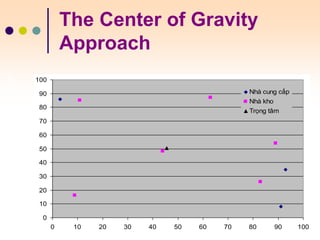

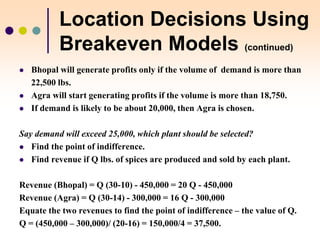

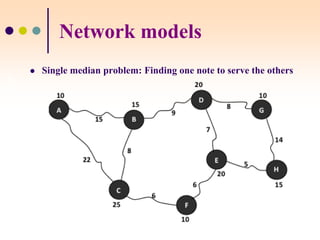

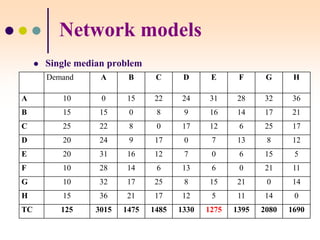

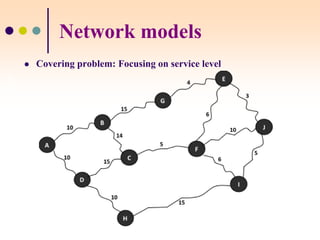

The document discusses various facility location models and methods for evaluating location alternatives. It describes factors to consider in site selection such as labor costs, proximity to markets and suppliers, infrastructure, and transportation. Location analysis should identify dominant factors, develop location alternatives, and evaluate them using methods like factor rating, load-distance modeling, center of gravity, and break-even analysis. The document provides examples demonstrating how to apply these models to make optimal location decisions.