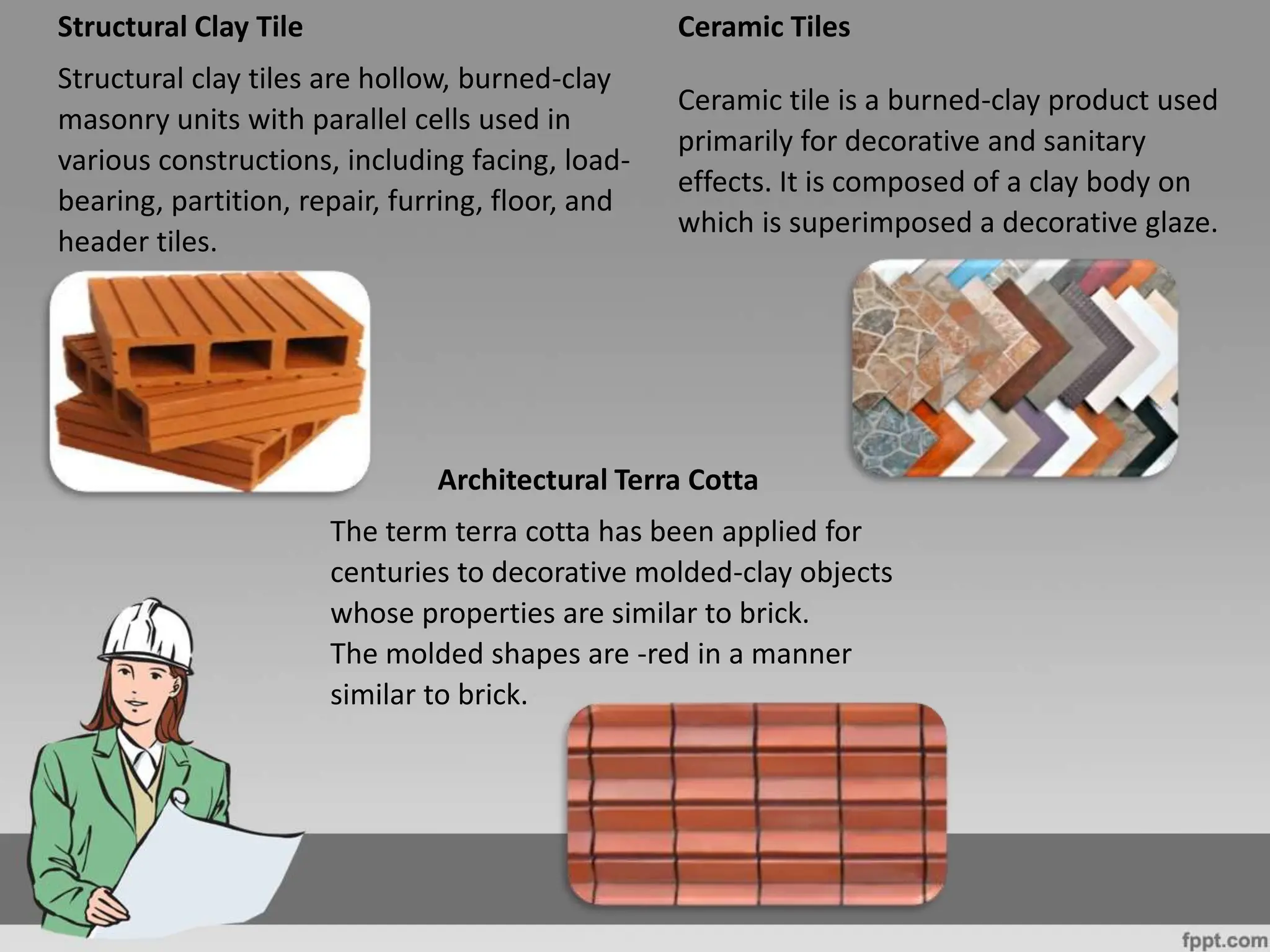

This document provides information on various building materials used in construction including cementitious materials, aggregates, admixtures, mortars, concretes, burned clay units, building stones, gypsum products and glass. It describes the composition and properties of materials like Portland cement, masonry cement, lightweight aggregates, fibers, polymer concrete and glass block. Specification details are provided for materials selection in construction projects.