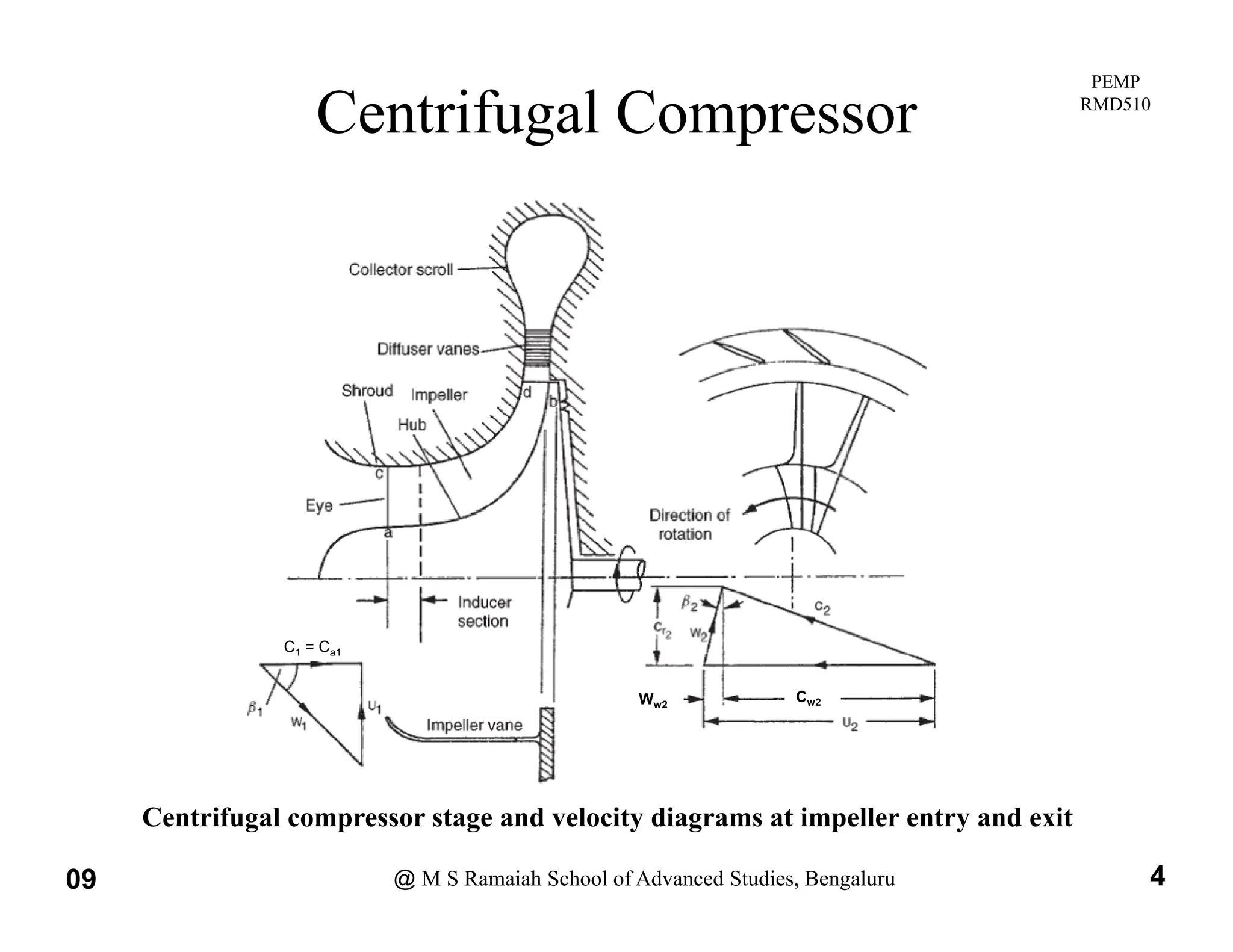

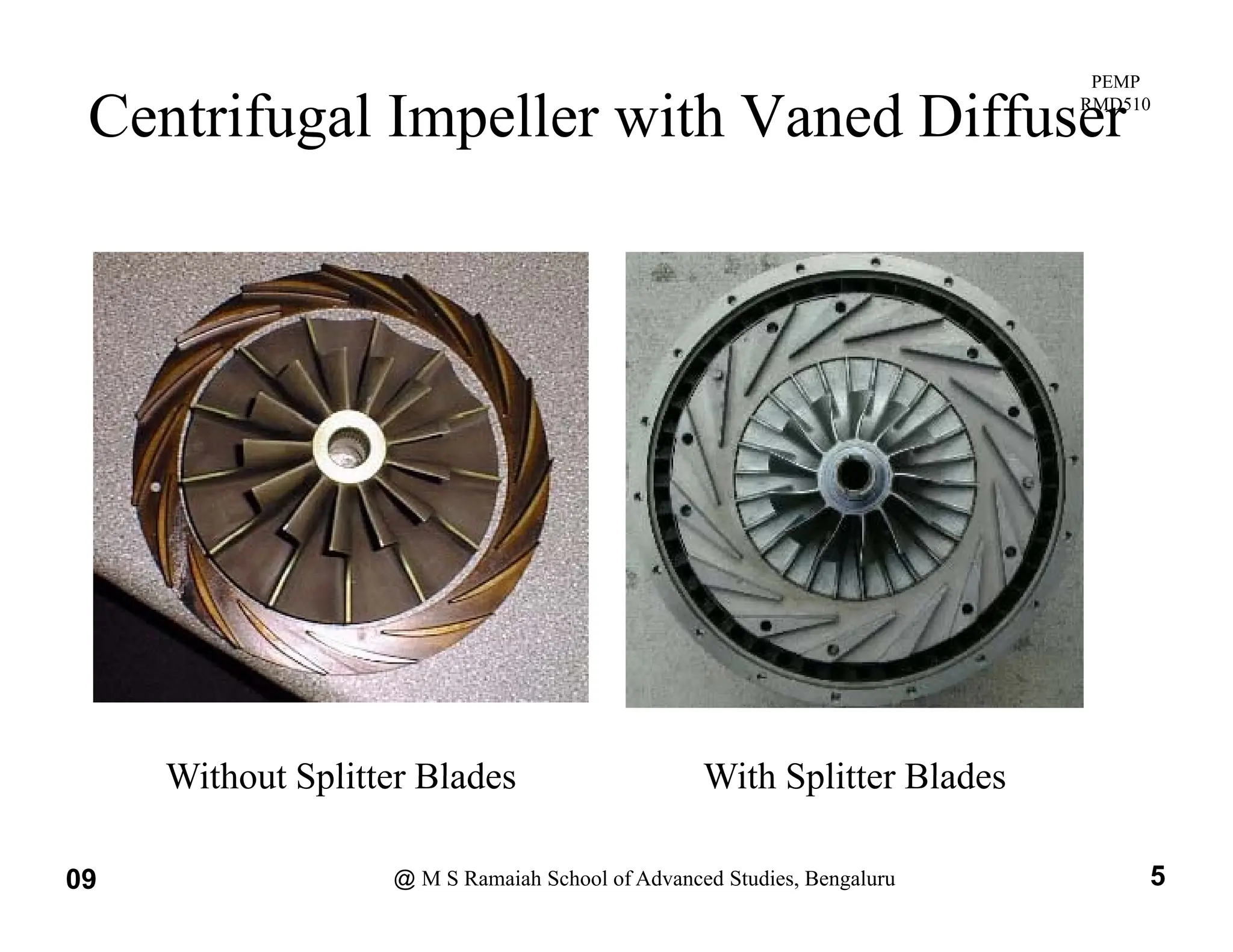

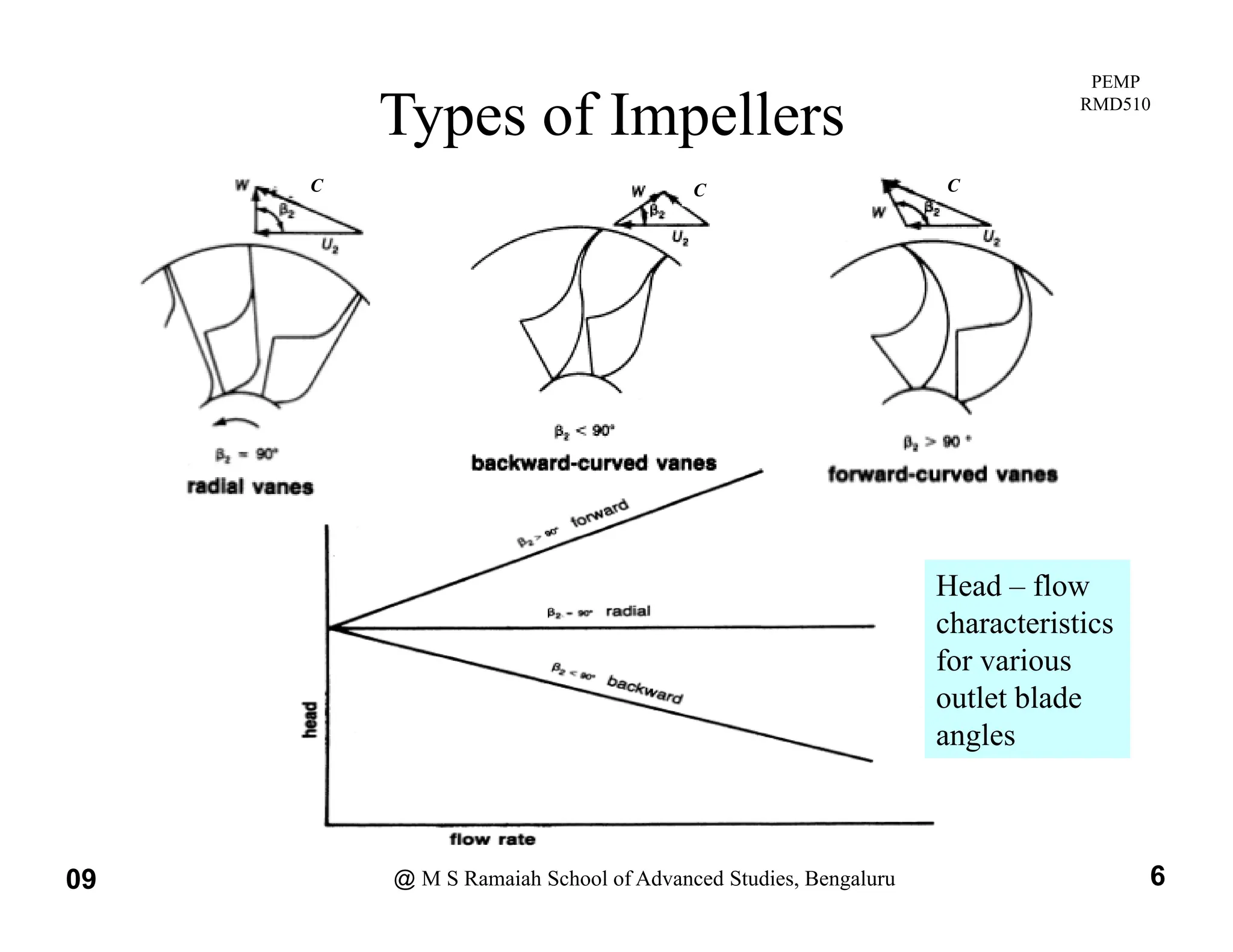

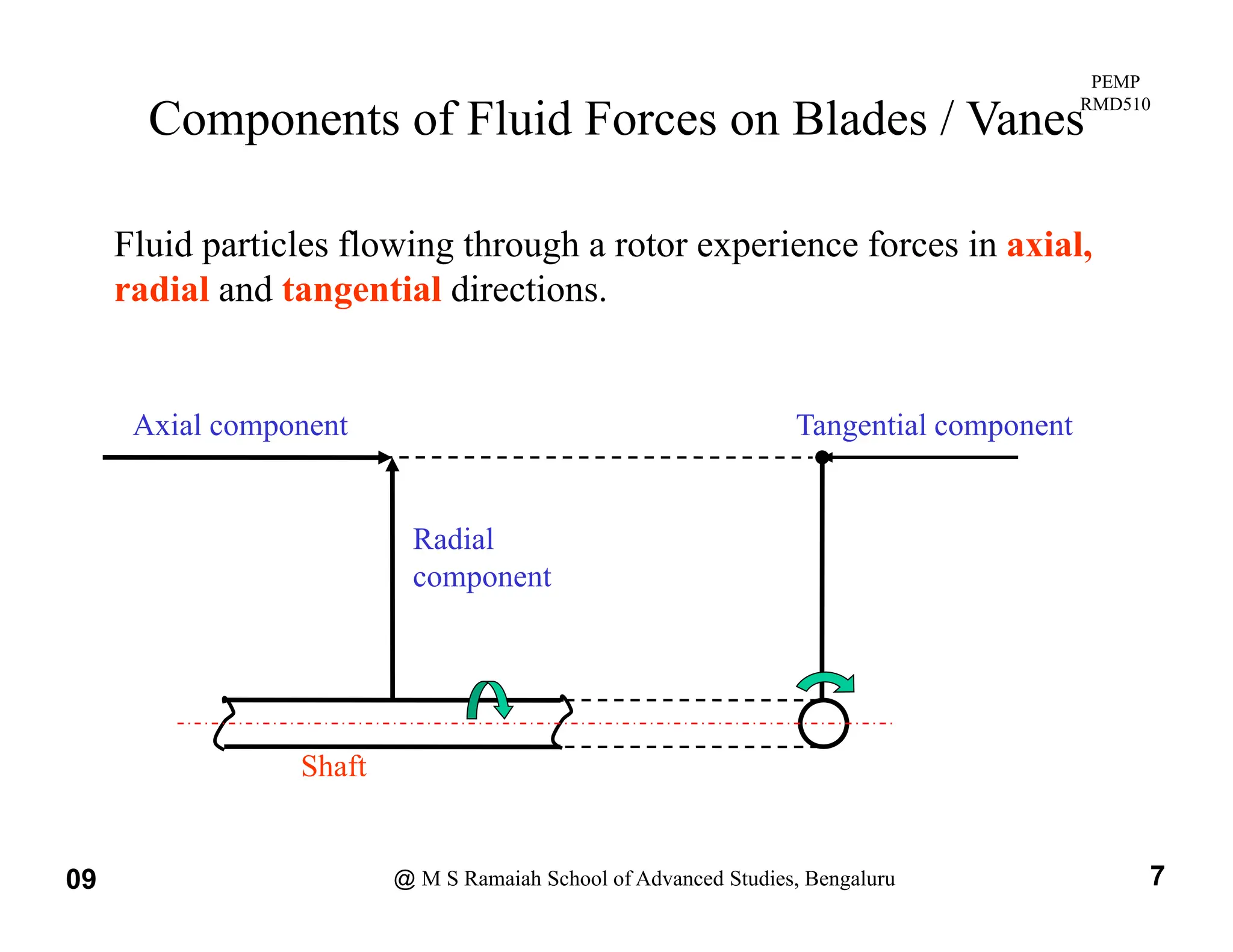

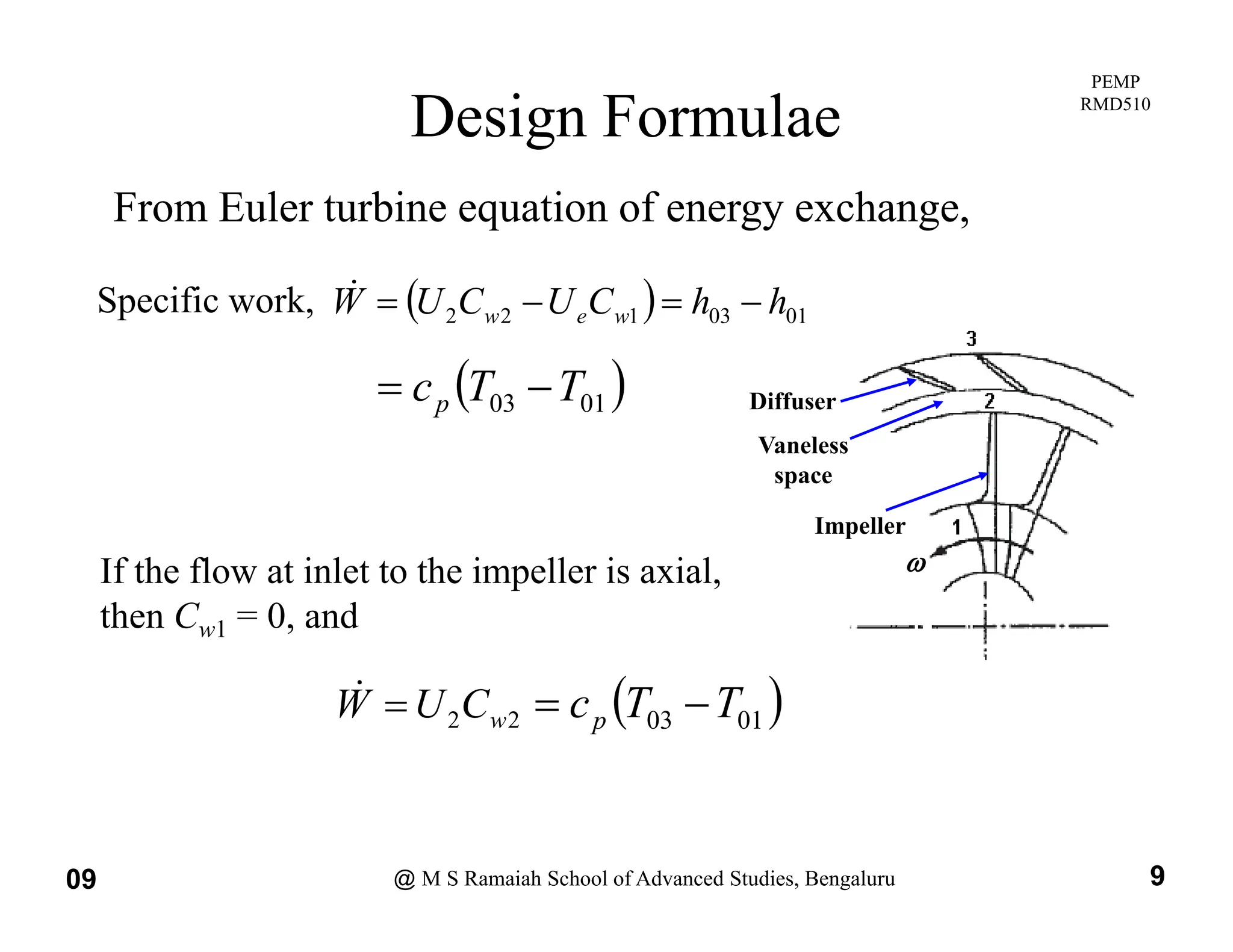

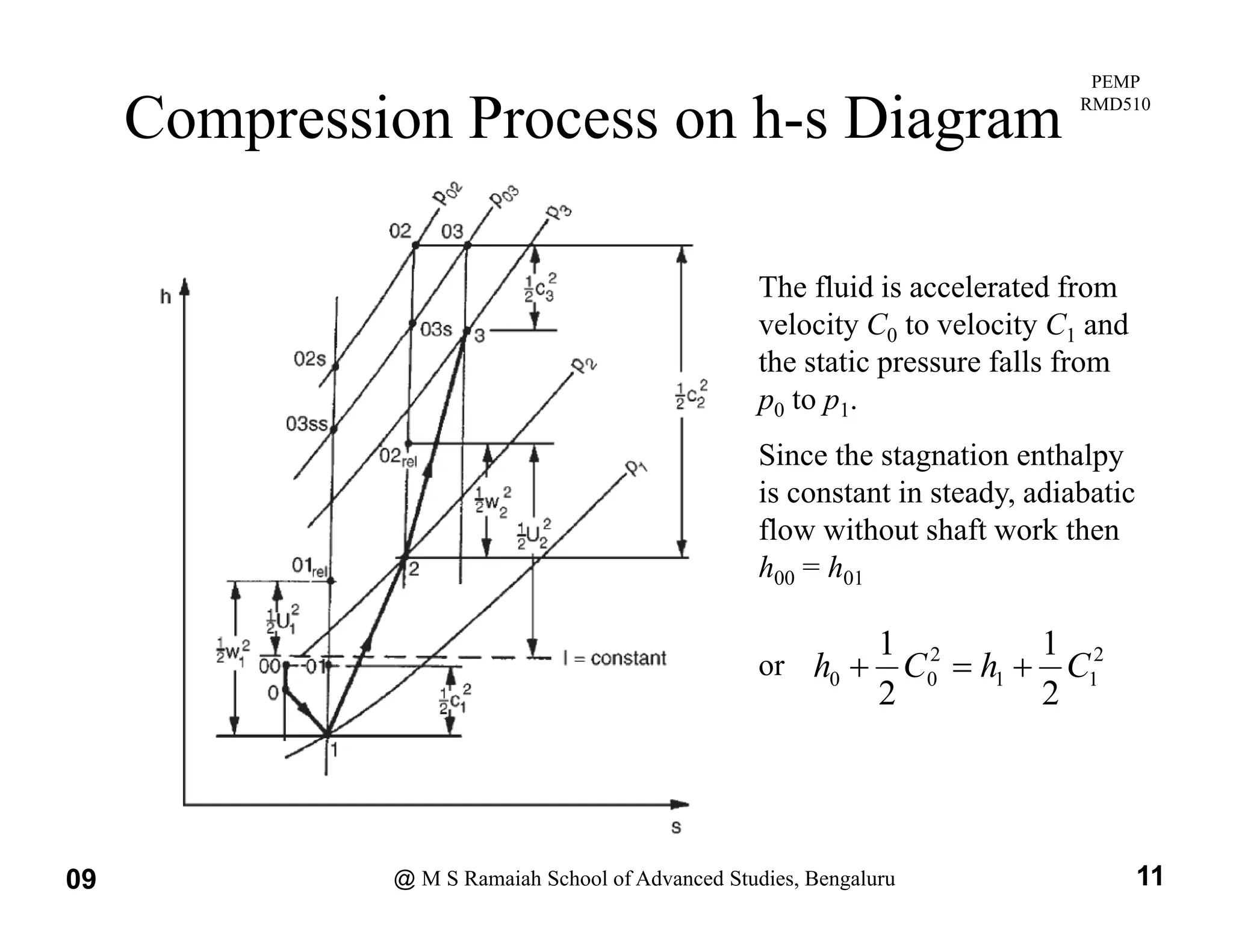

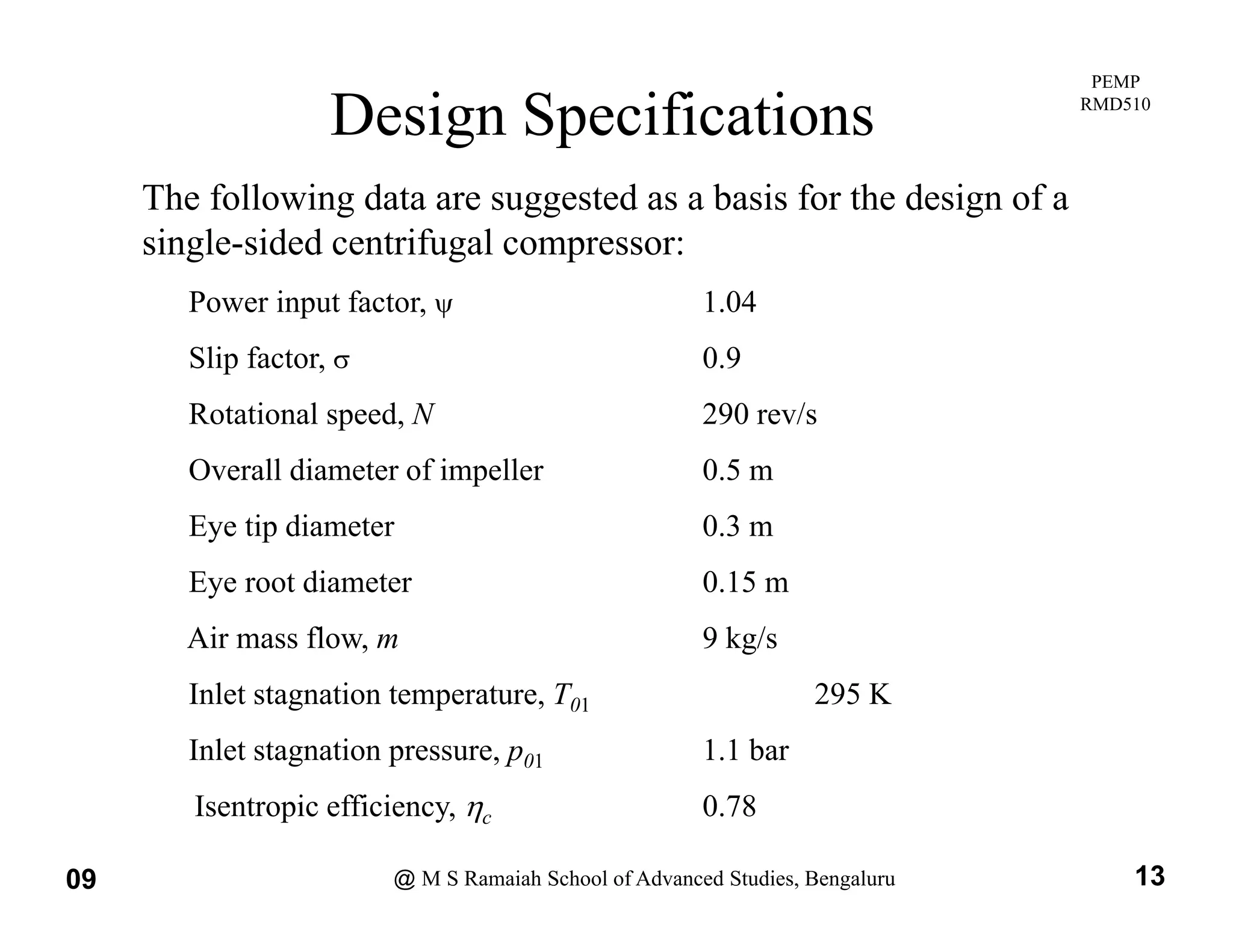

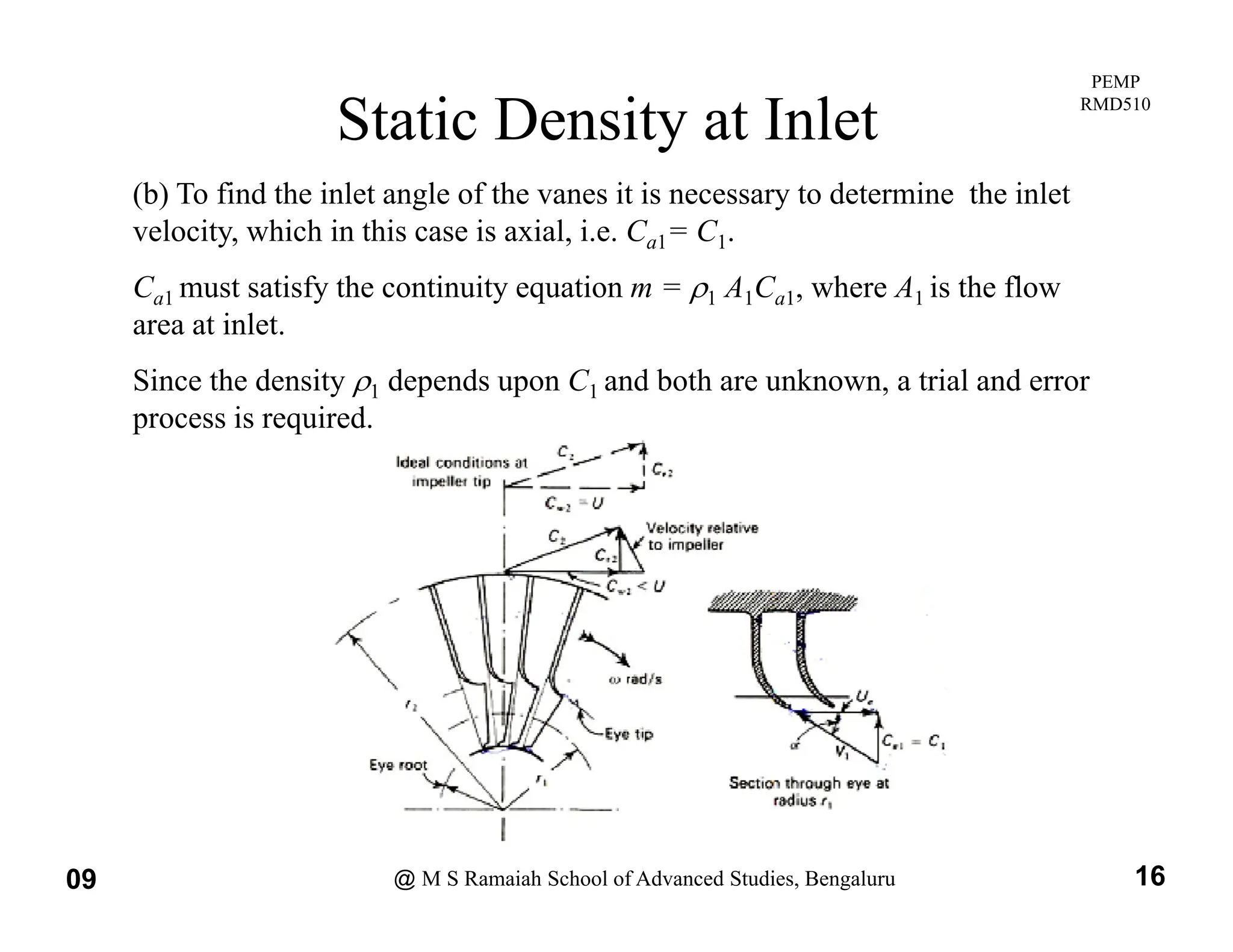

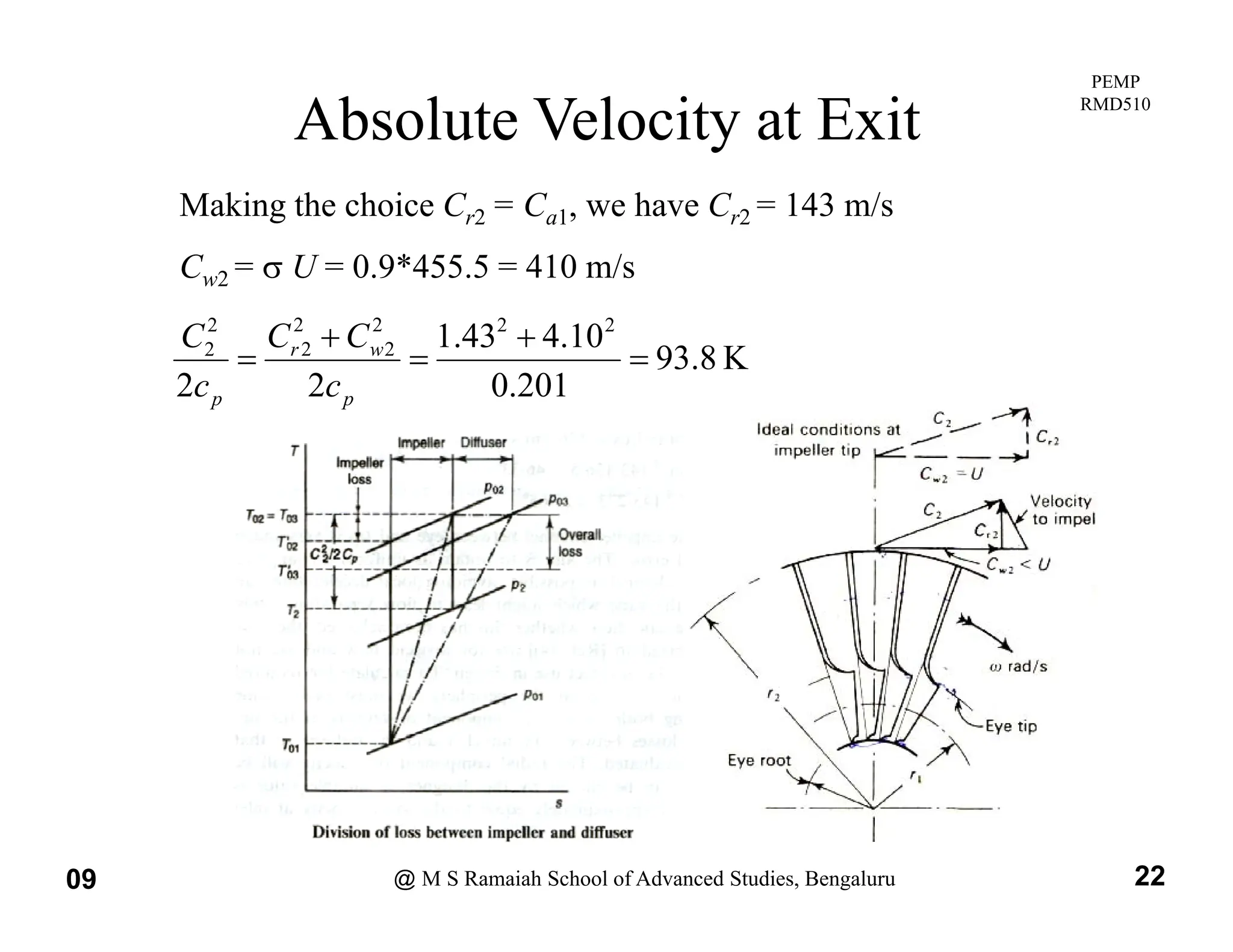

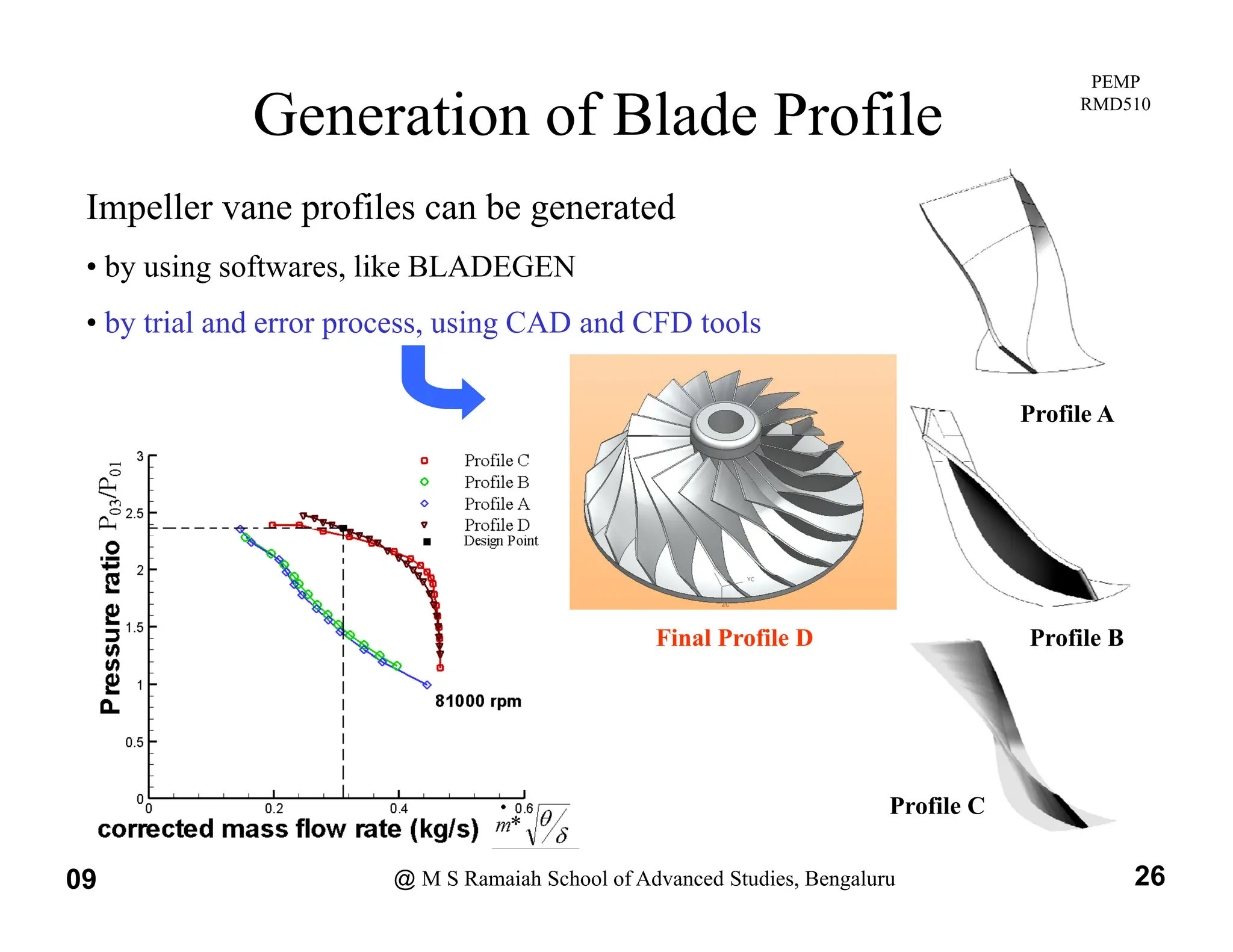

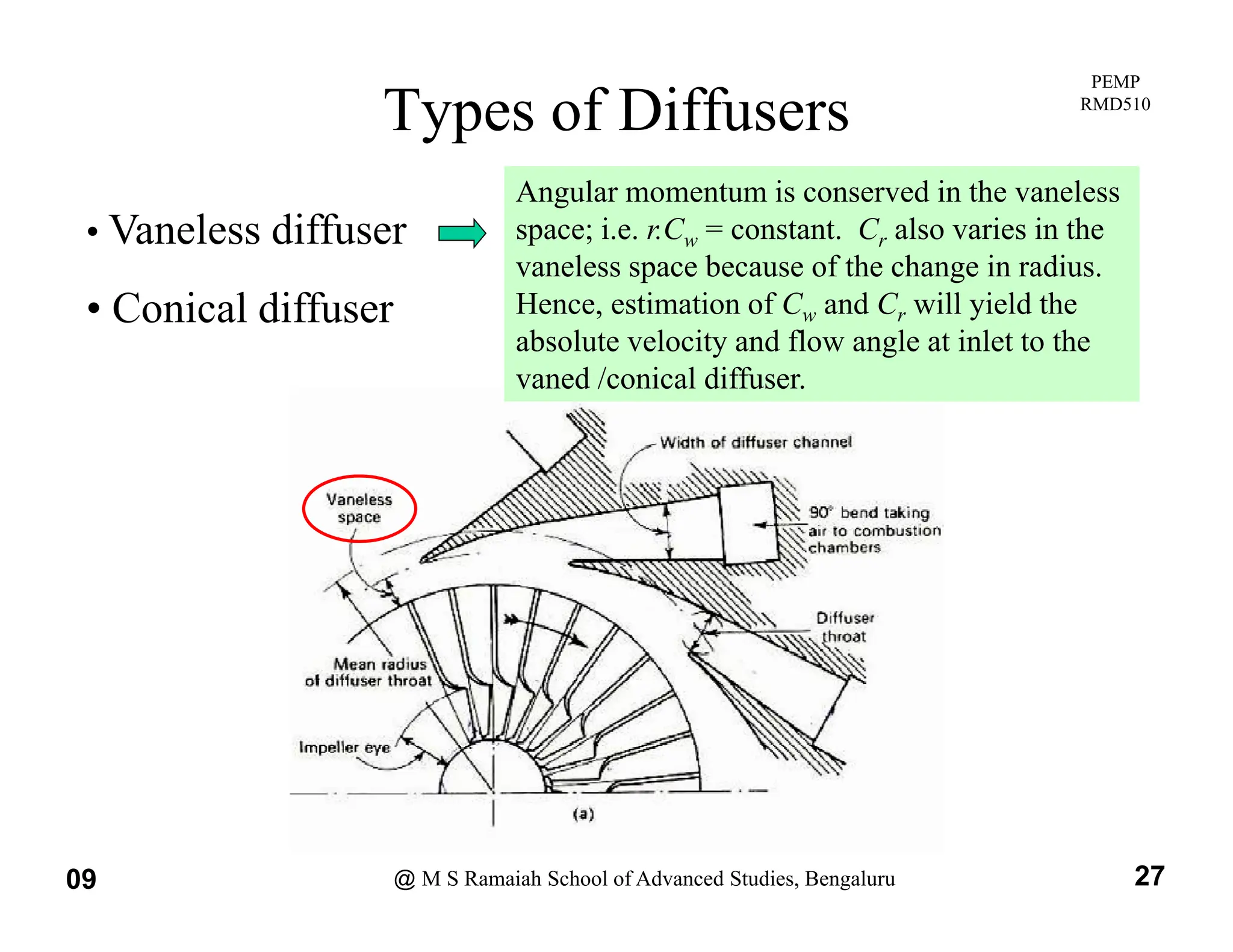

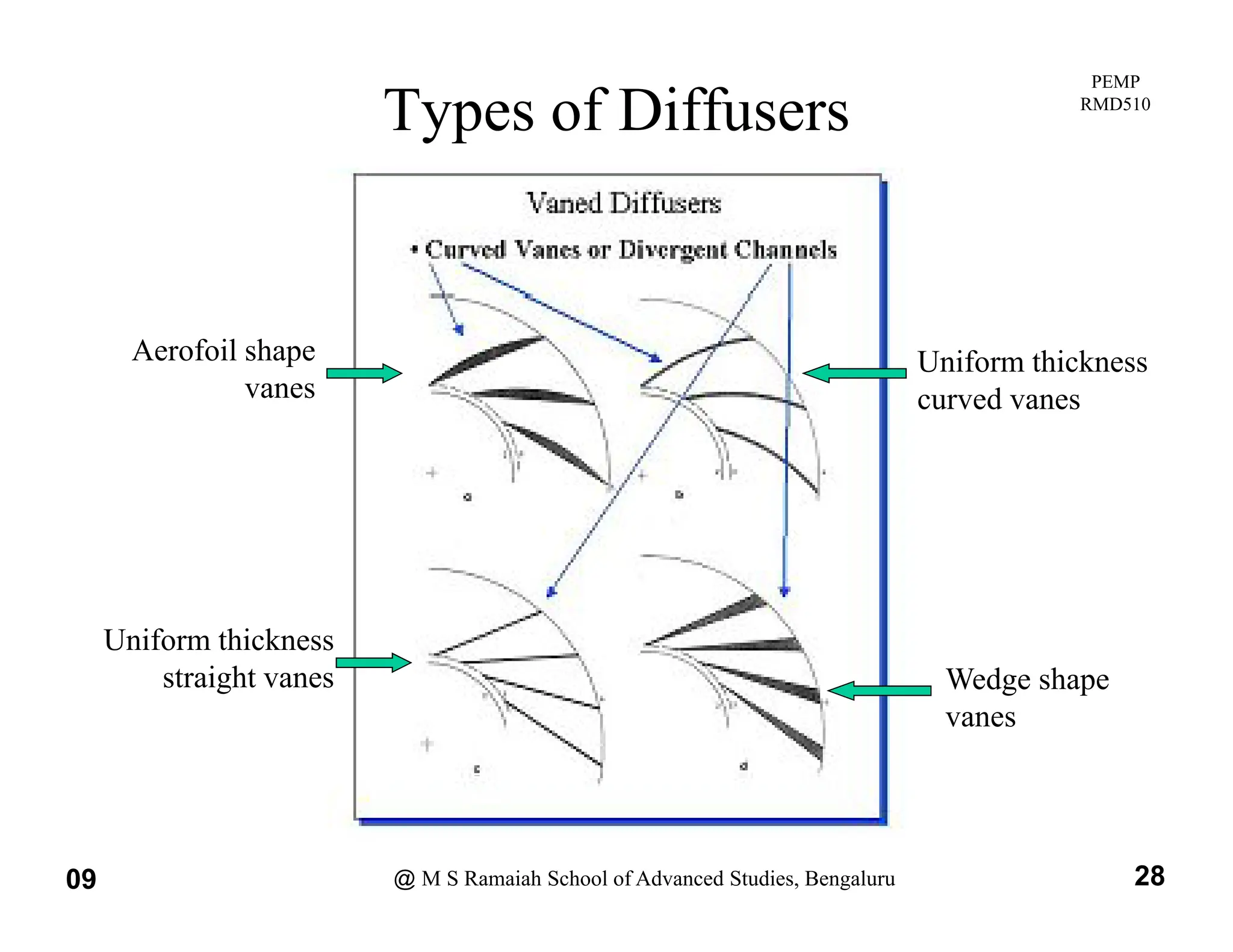

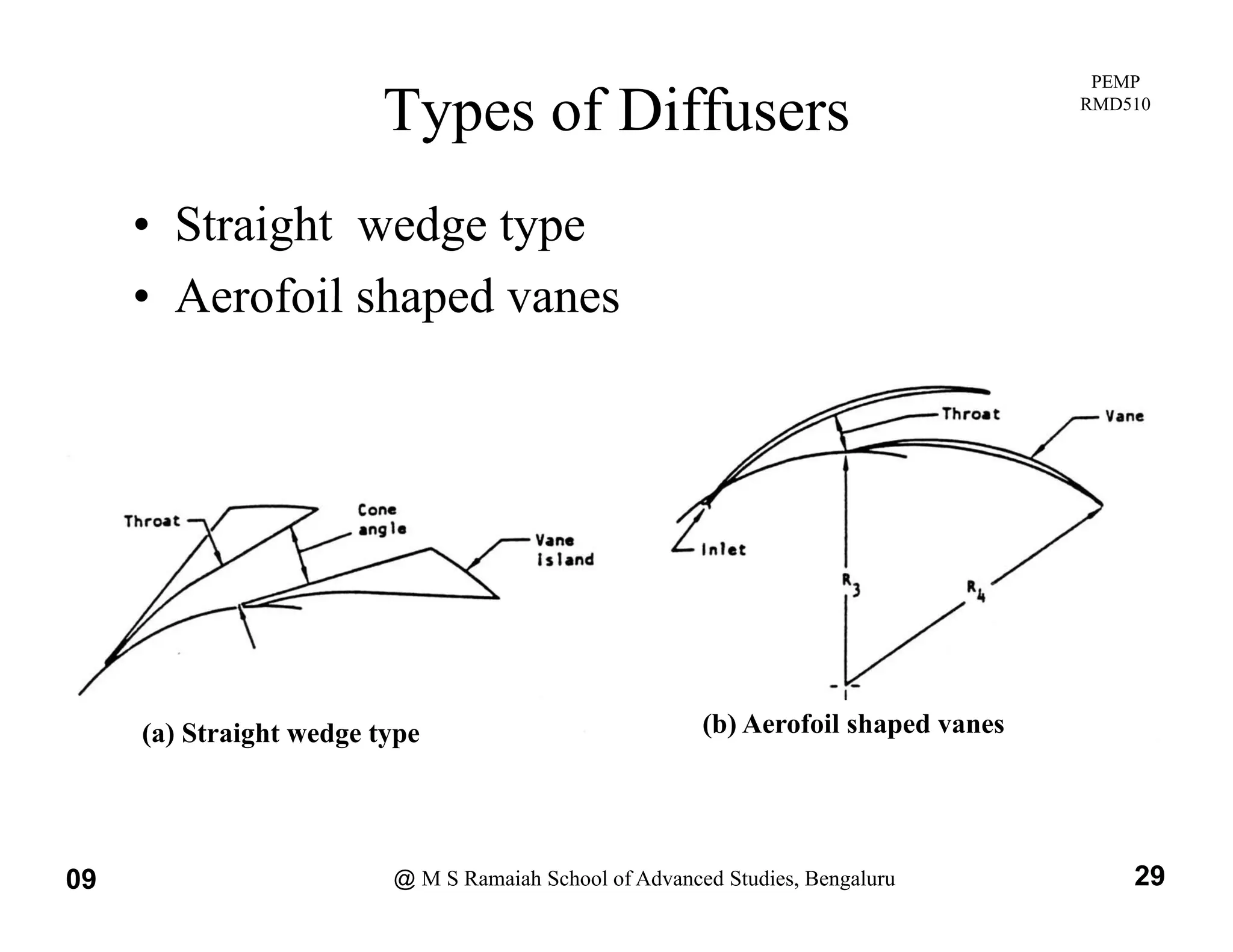

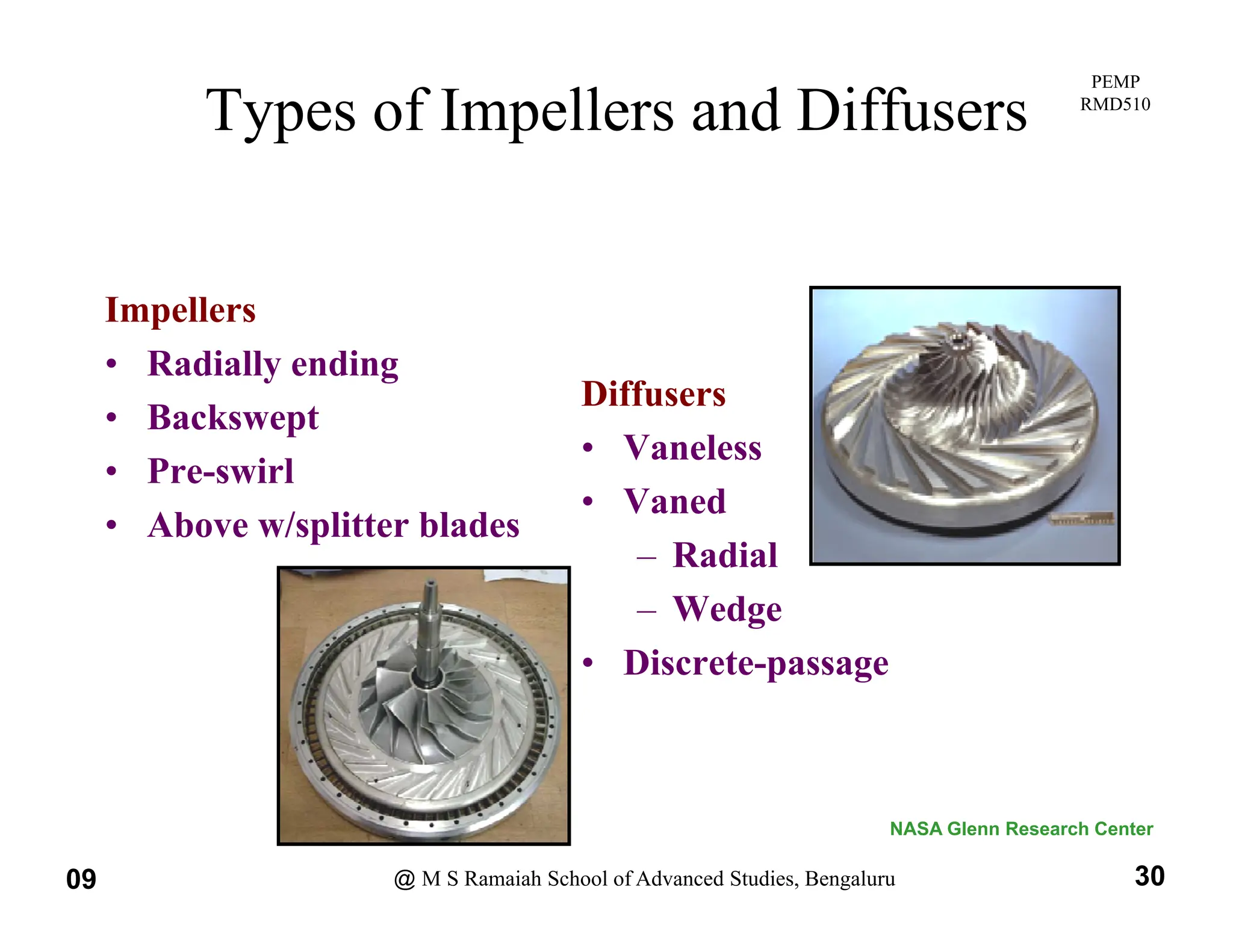

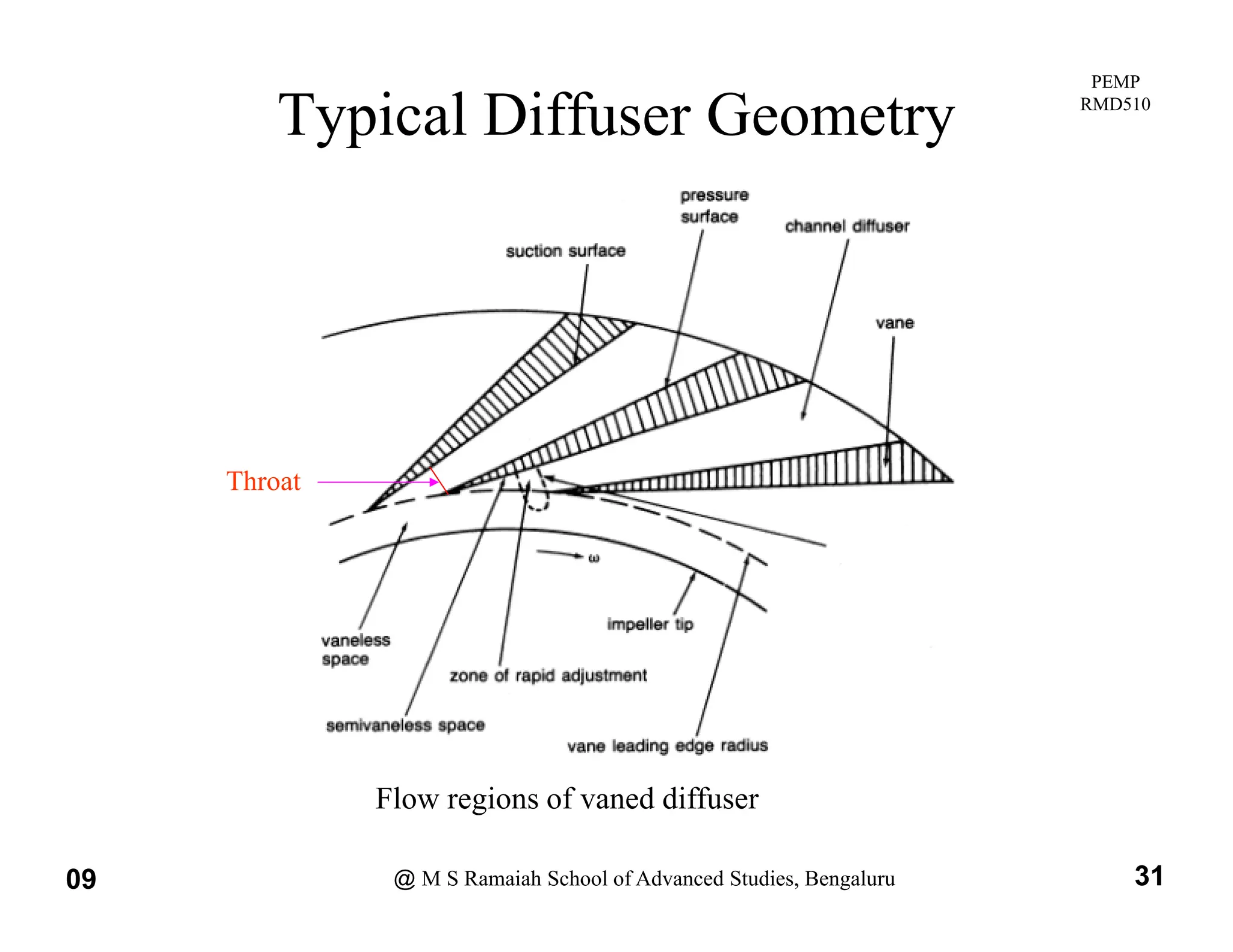

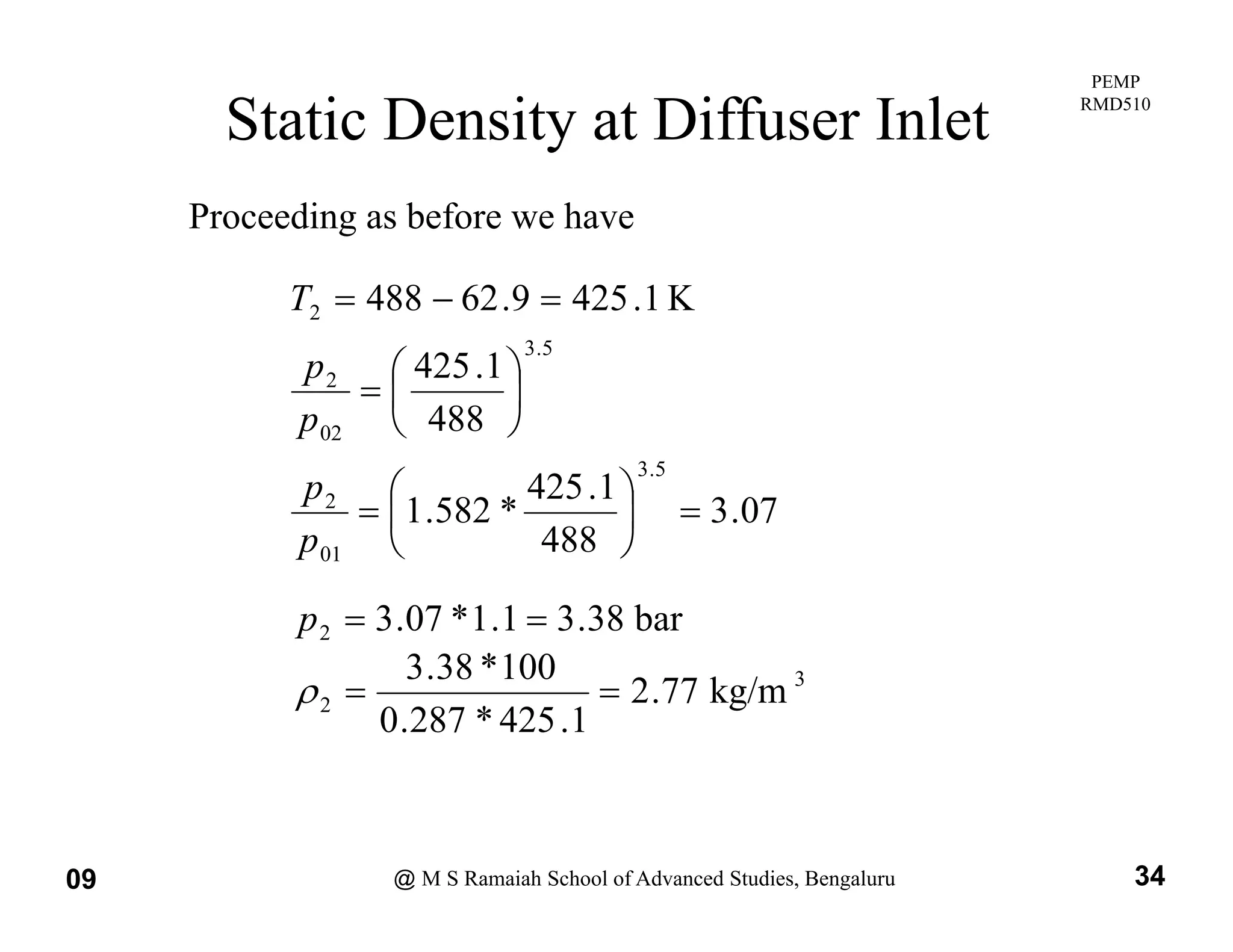

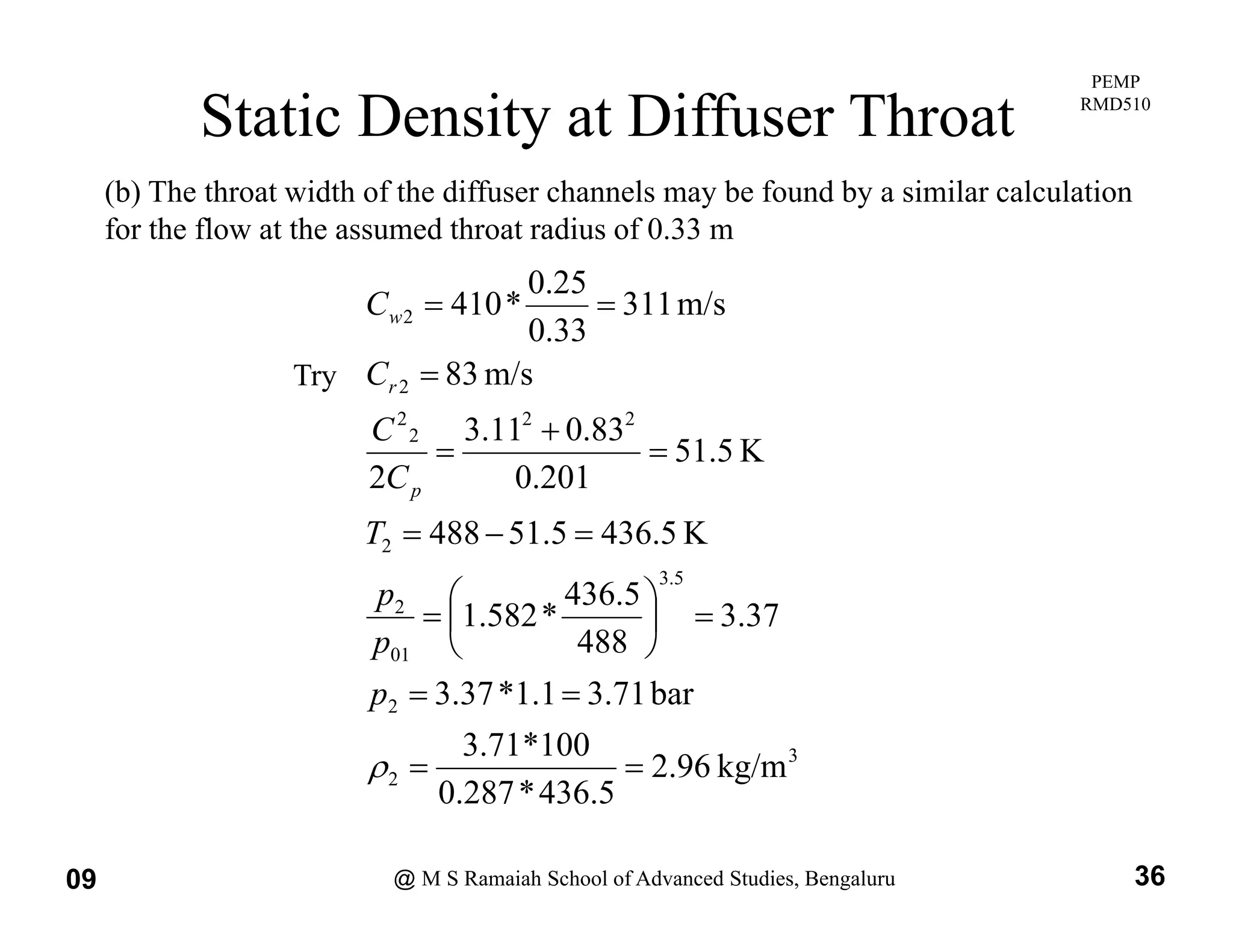

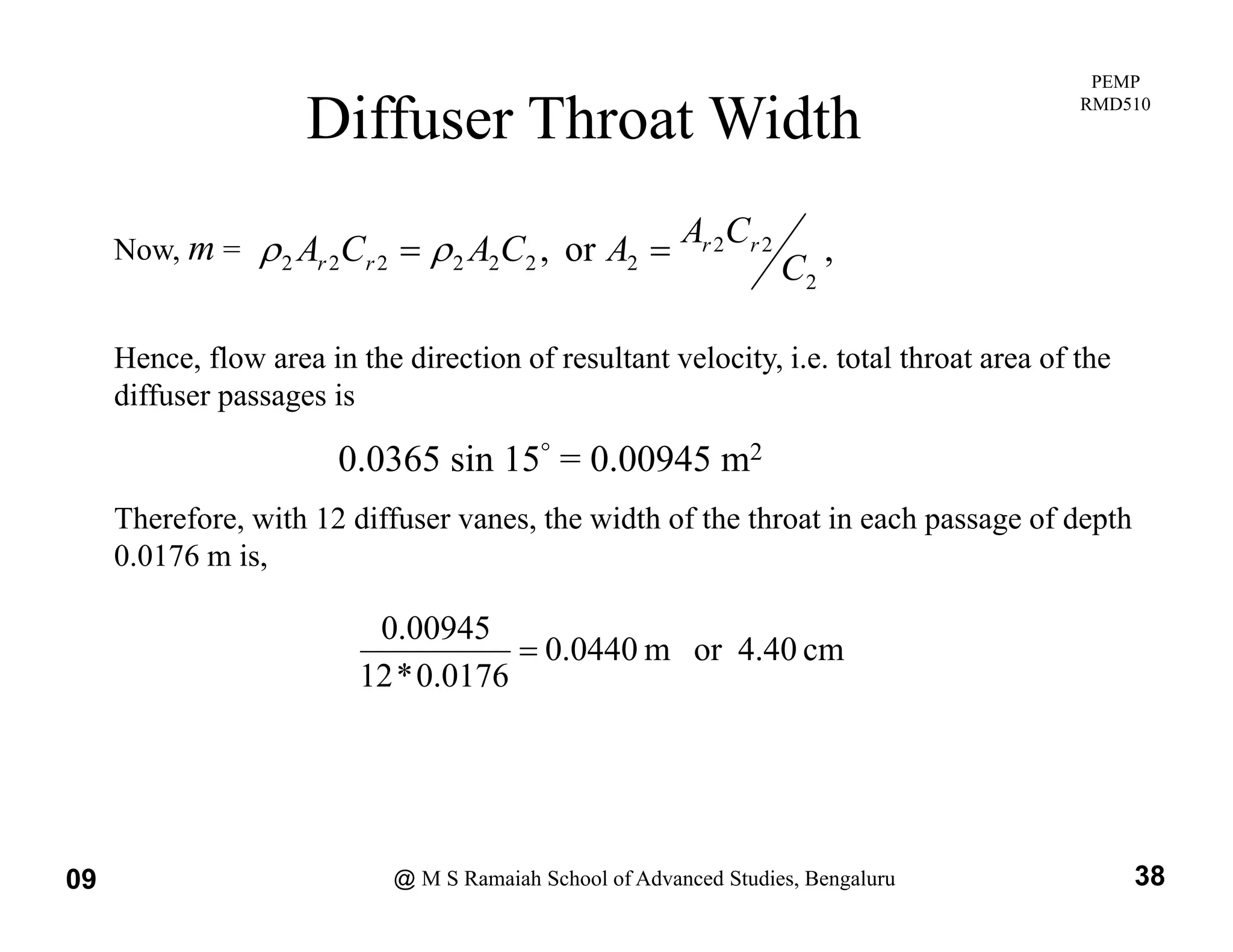

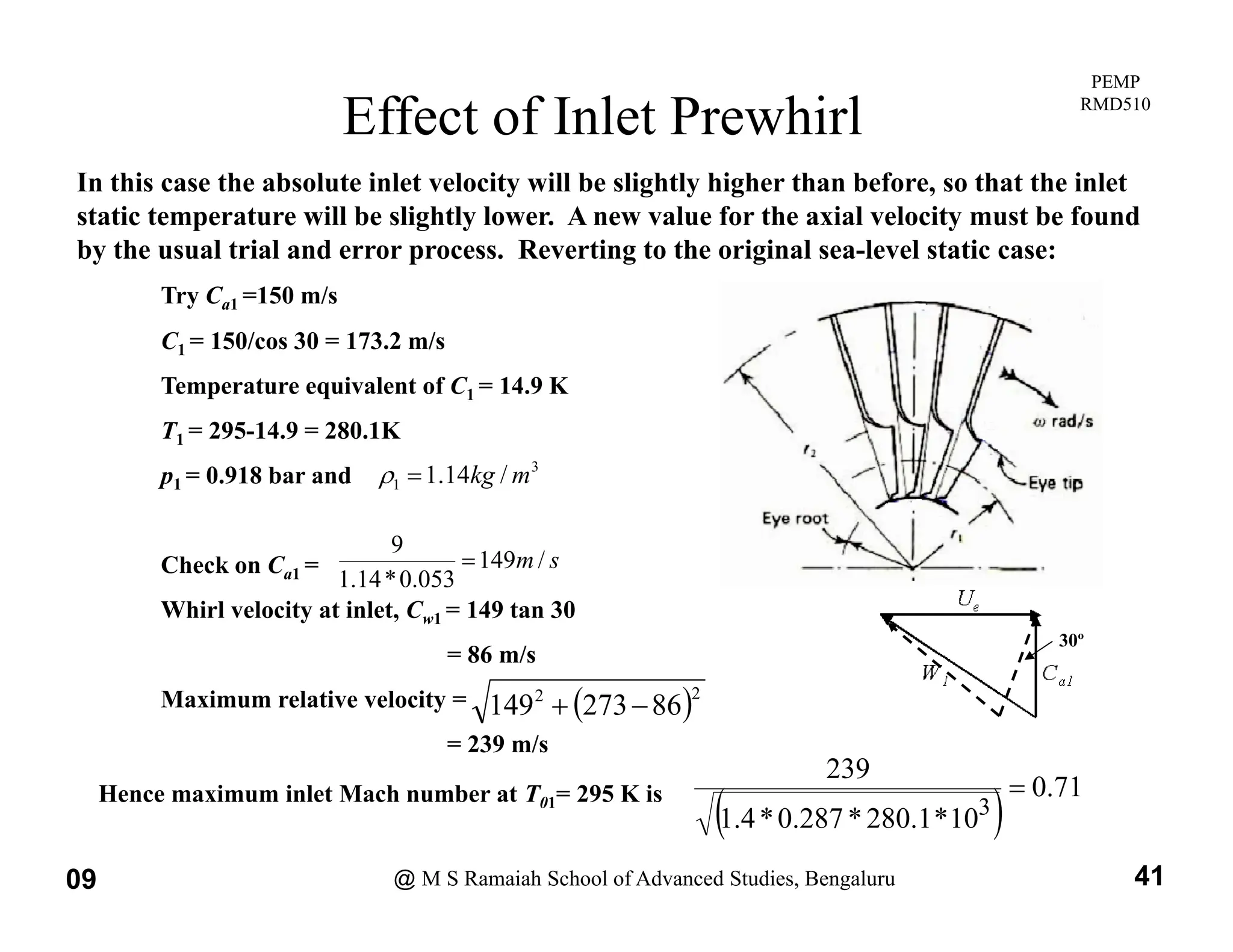

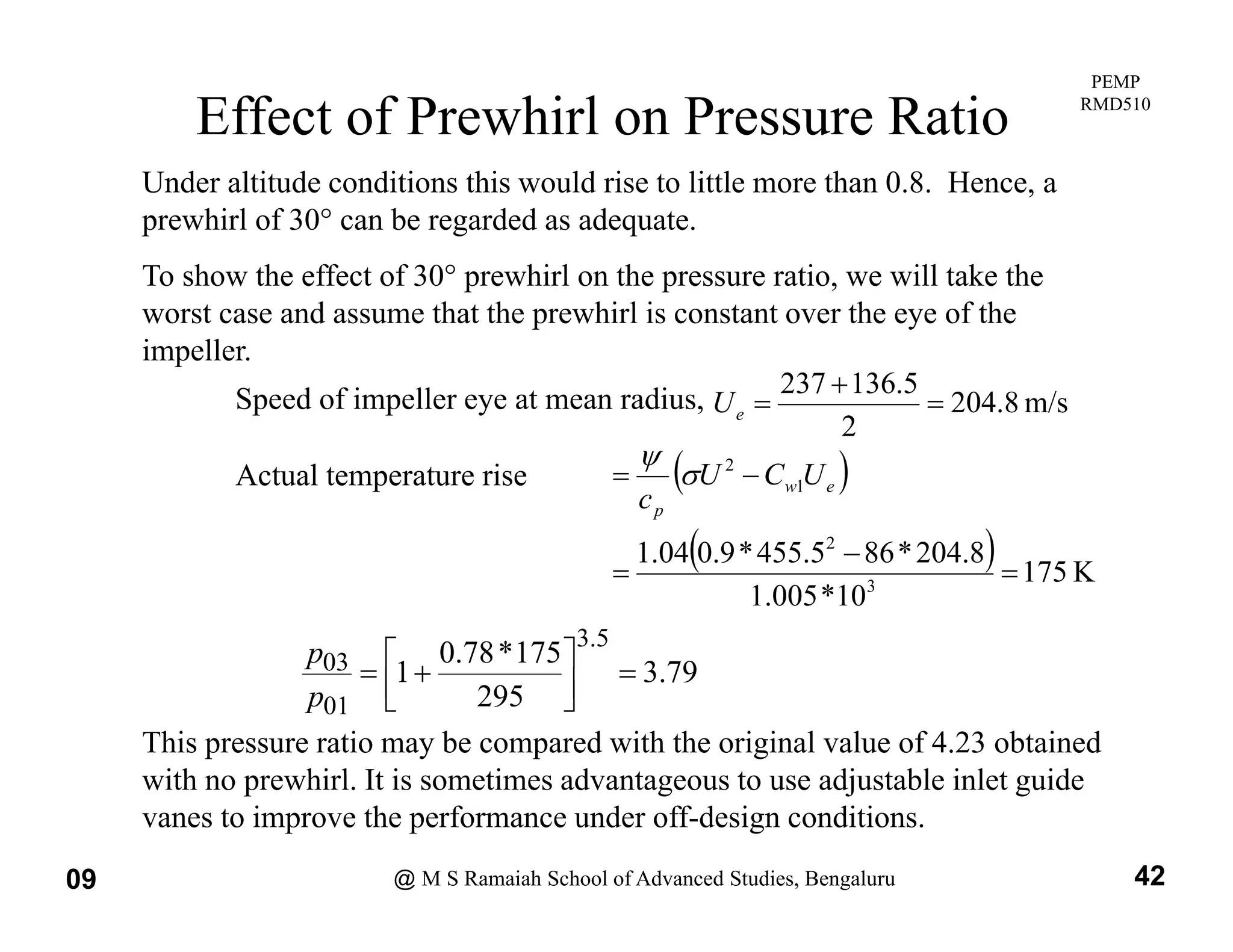

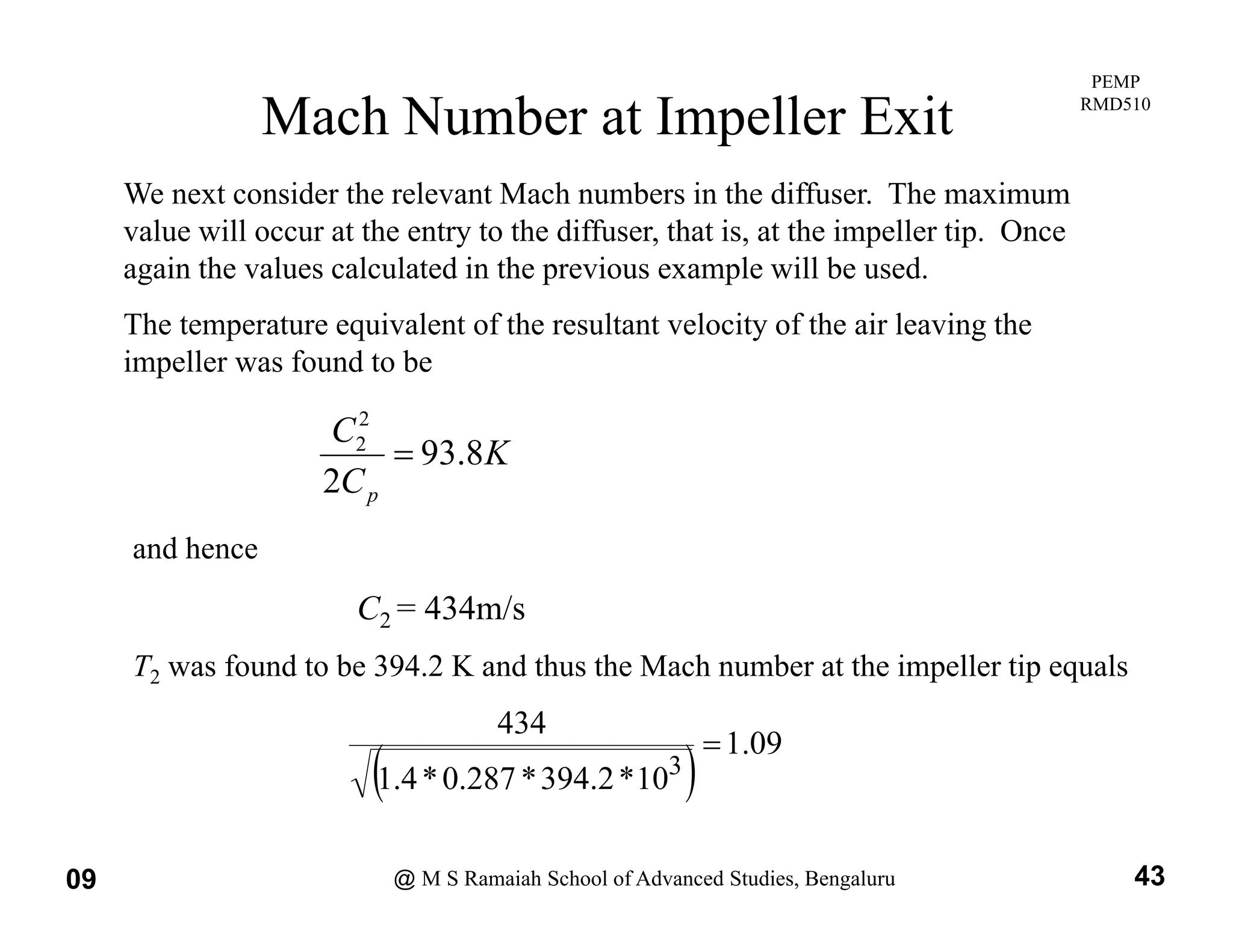

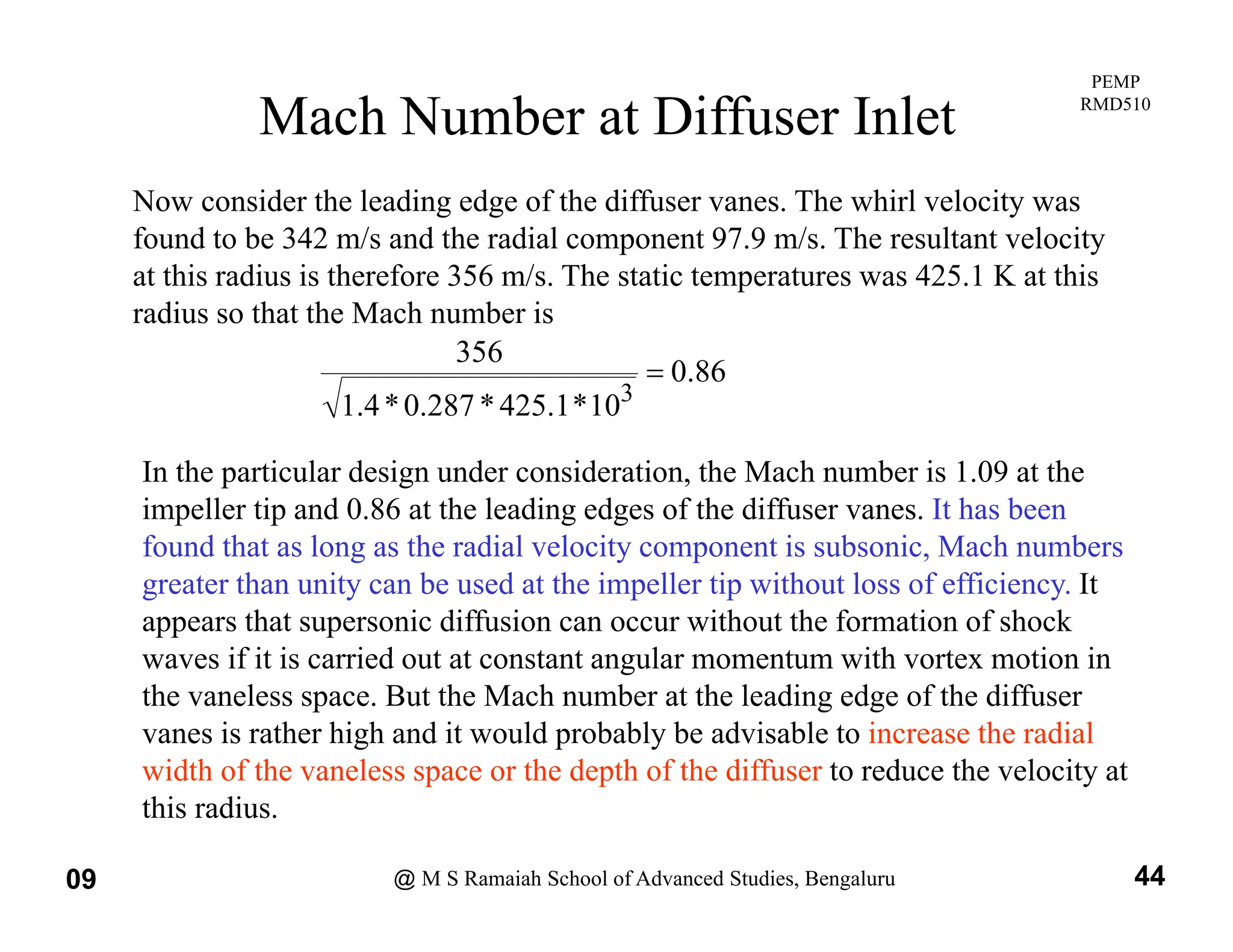

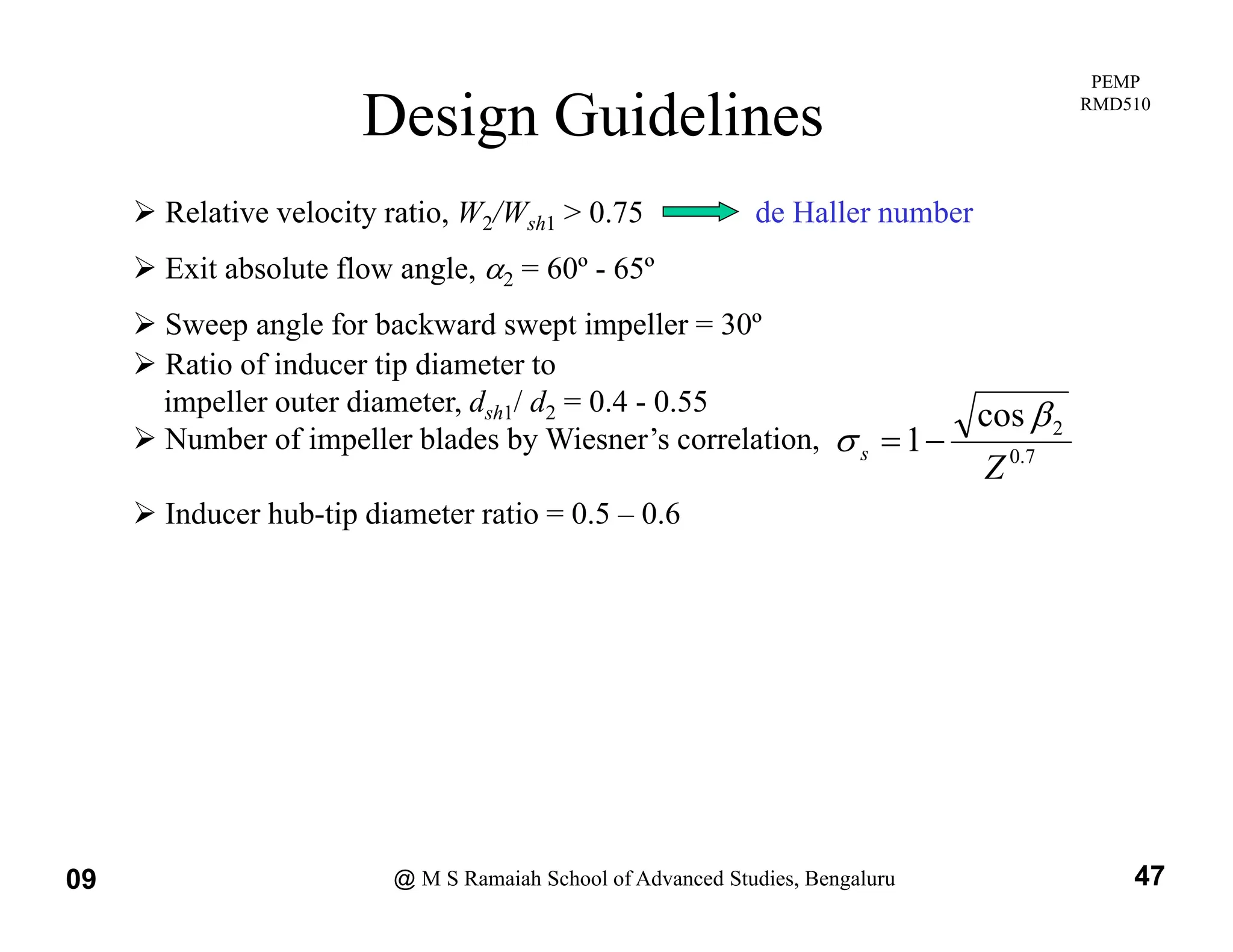

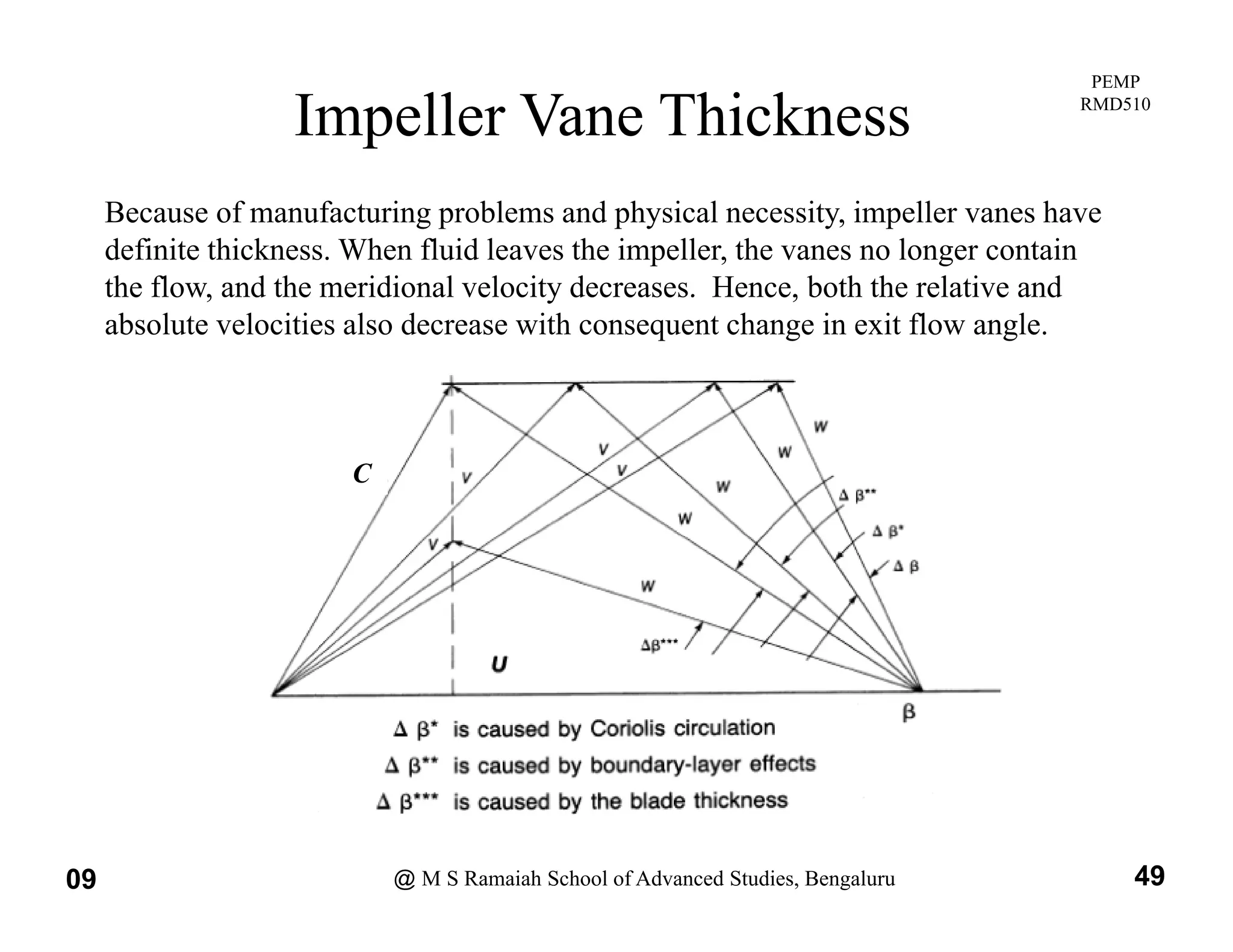

The document provides a detailed overview of the aerodynamic design process for centrifugal compressors, covering impeller geometry, diffuser design, and performance parameters. It includes design procedures, formulae, and components affecting compressive efficiency, as well as design specifications for a single-sided centrifugal compressor. The session aims to equip delegates with essential knowledge on the principles and methodologies used in centrifugal compressor design.