1. The transportation of concrete from mixing plant to construction site is an important activity that can impact the properties of the concrete if not done properly. The time taken in transit should be considered during design.

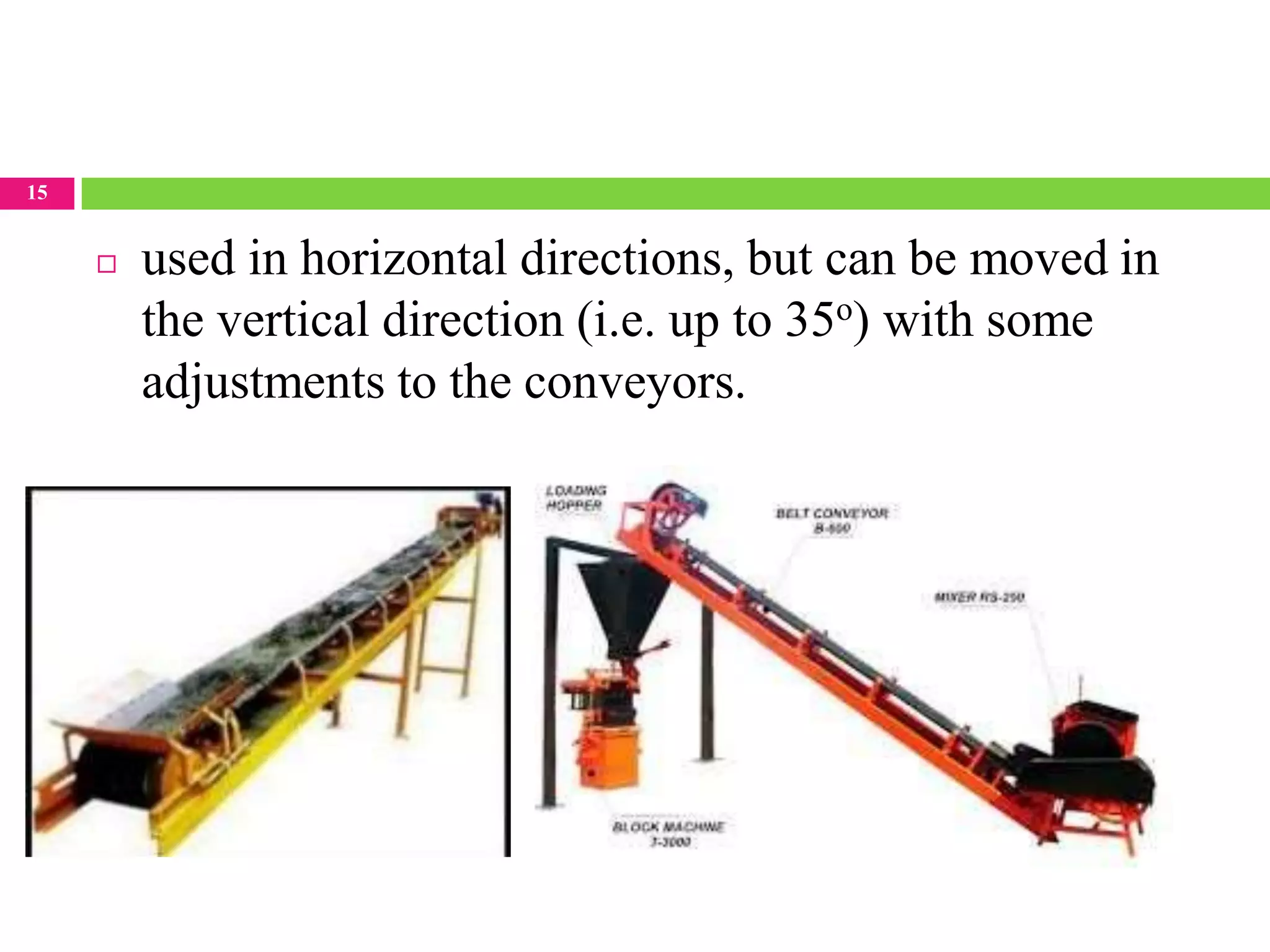

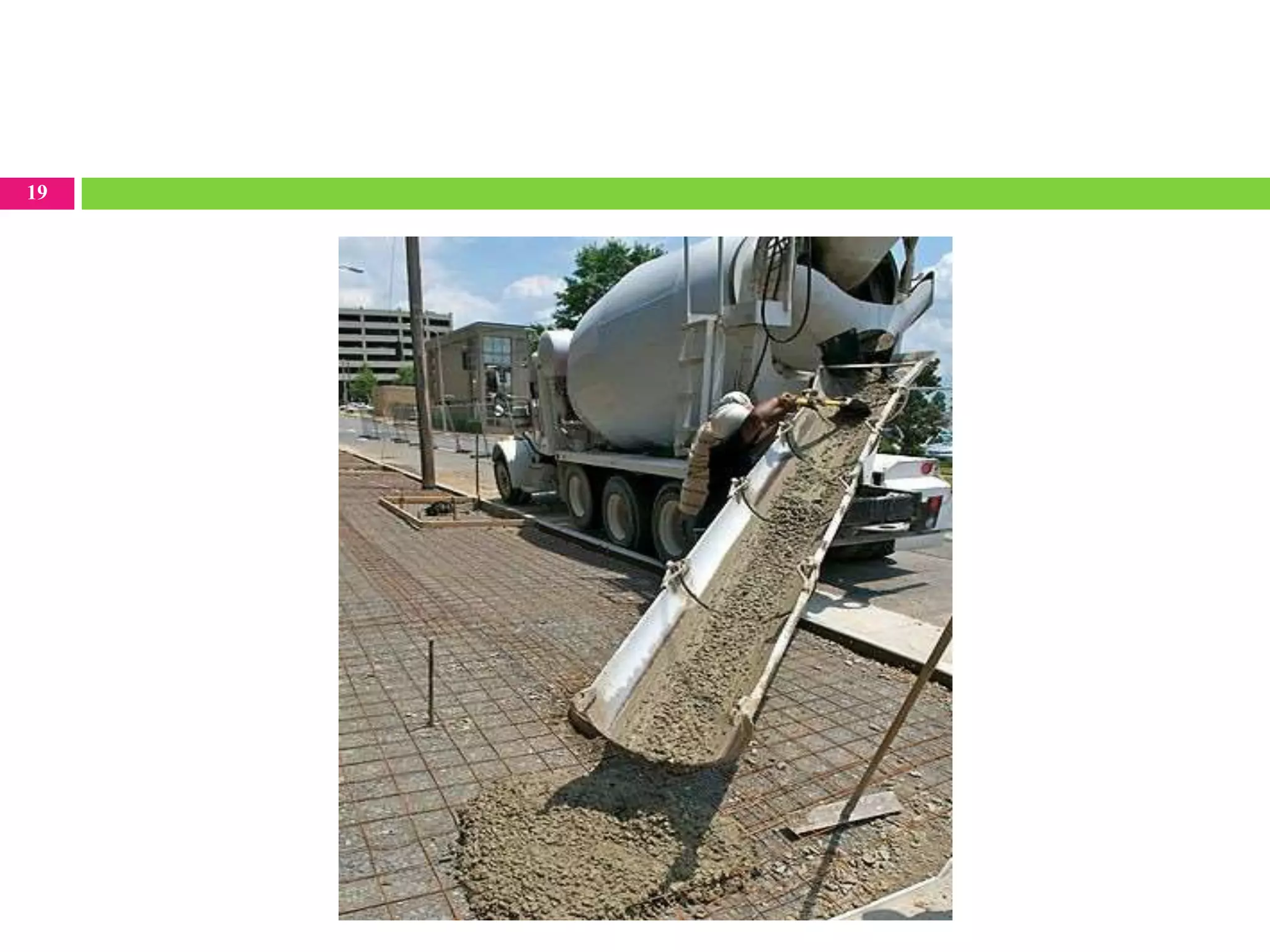

2. Several methods are used for concrete transportation including wheelbarrows, trucks, buckets, conveyor belts, chutes, and helicopters. Proper selection depends on factors like volume needed, location, and environmental conditions.

3. The main goals of transportation are to prevent segregation of aggregates and loss of workability, and to deliver concrete with the intended water-cement ratio, slump, air content, and homogeneity. Guidelines recommend discharging concrete within 1-2 hours depending on the transportation and