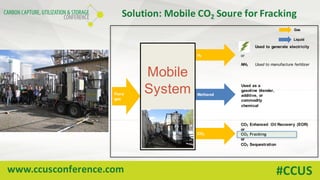

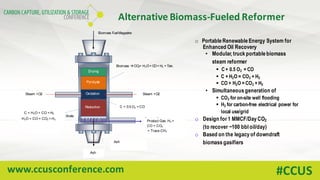

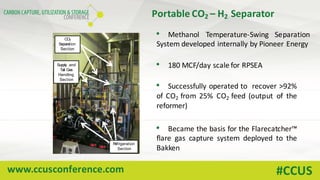

- Pioneer Energy has developed a portable system that can generate high-purity CO2 and electricity from raw field gas or biomass on-site at oil fields.

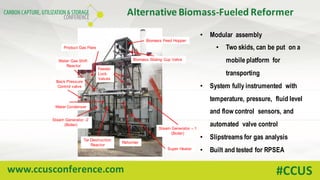

- The fully portable system fits on a semi-trailer and can produce 200-1,000 mcf/day of CO2. A prototype has been built and tested.

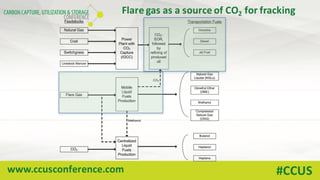

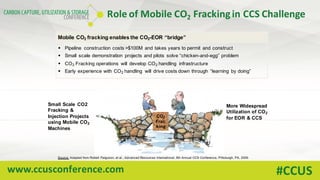

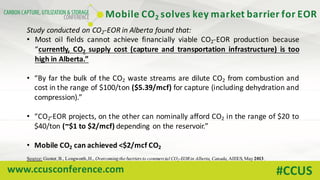

- The system addresses the lack of available and affordable CO2 for fracking and enhanced oil recovery (EOR) projects. It provides an on-site source of CO2 without the need for pipelines or trucking.

- By using flare gas, a wasted resource, the system also addresses environmental issues. It has the potential to enable more small-

![www.ccusconference.com #CCUS

Wasted flare gas is both an economic &

environmental problem

North Dakota from Space

In 2014… only 10% reduction in ND from oil price drop in 2016

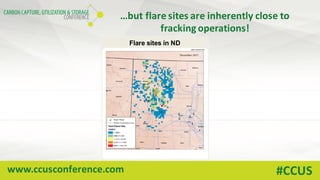

Alberta, Canada flared 1.1 billion cubic meters per year ……. 39 BCF/yr

North Dakota flared 120 billion ft3 per year ……………………120 BCF/yr [107 BCF/yr in 2016]

World flared 7 trillion ft3 (TCF) per year …………………….. 7,000 BCF/yr

Alberta from Space](https://image.slidesharecdn.com/e0aa96f4-5c9e-4113-9994-8c3b2d243a04-160923200545/85/CCUS_Fracking-6-320.jpg)