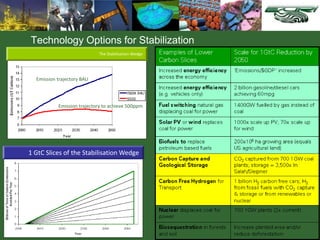

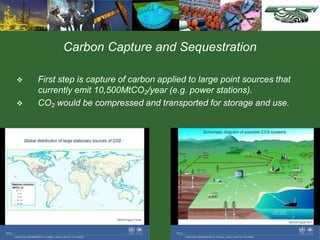

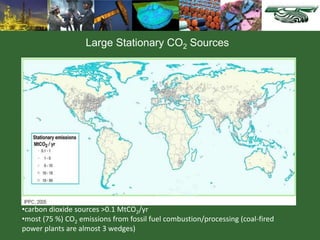

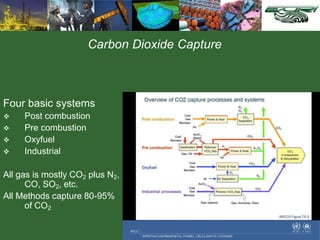

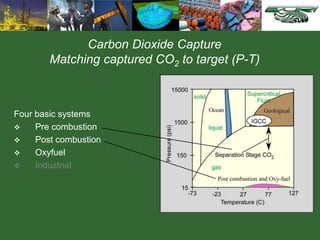

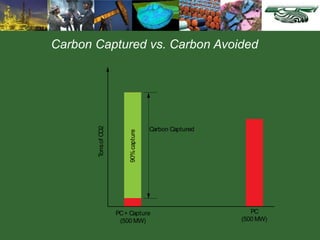

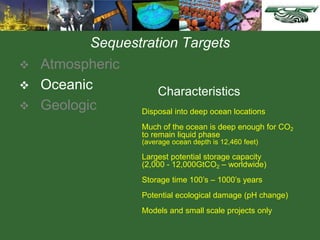

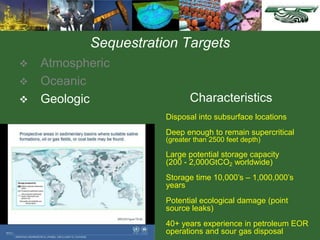

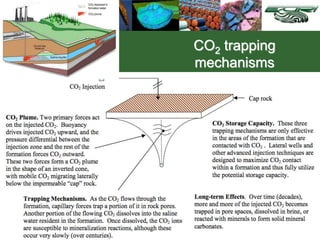

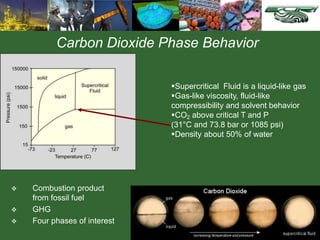

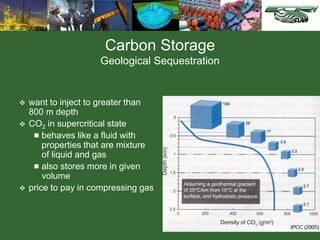

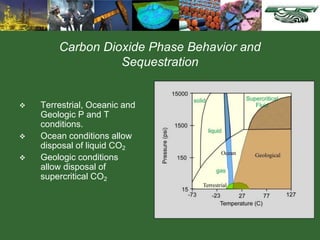

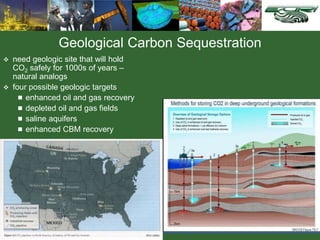

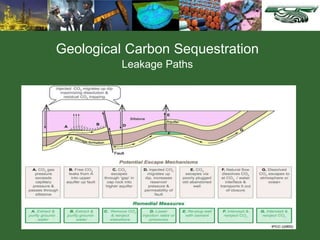

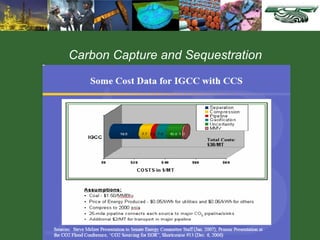

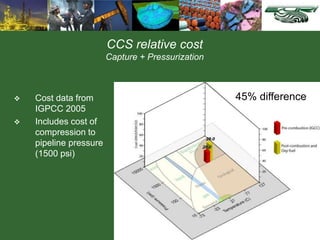

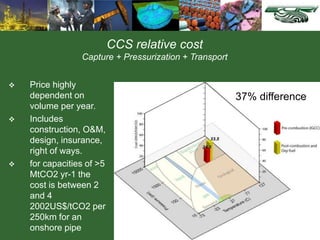

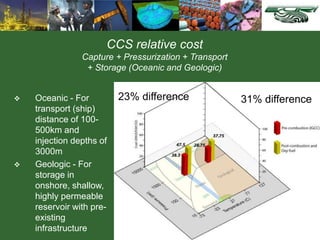

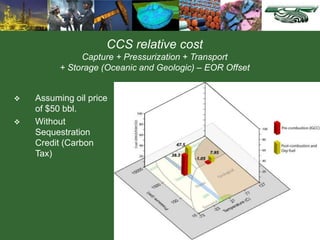

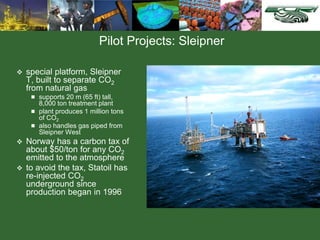

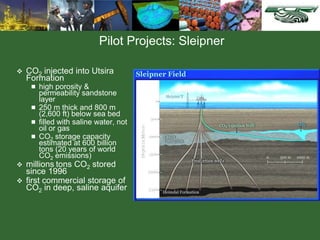

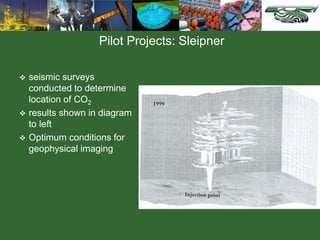

Carbon capture and storage has the potential to allow continued use of fossil fuels while mitigating climate change. It involves capturing carbon dioxide emissions from large point sources like power plants, compressing and transporting the CO2 via pipeline, and injecting it into deep geological formations for long-term storage. While the technology is possible with current science, large-scale demonstration projects are still needed to reduce costs and prove safety and effectiveness. If a policy framework creates incentives to reduce carbon emissions, carbon capture and storage at the scale of the oil and gas industry could cost around $1 trillion annually but help achieve climate goals.