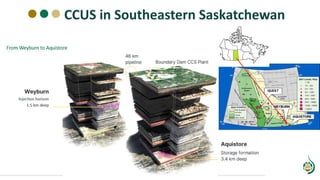

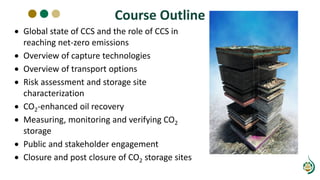

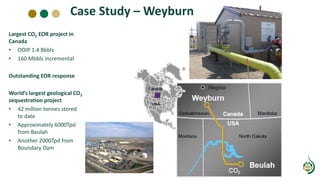

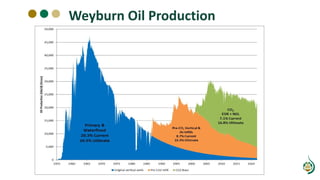

The document introduces Norm Sacuta and Brittney Musleh, who will present on carbon capture and storage. It then provides an overview of the Petroleum Technology Research Centre (PTRC), including that it is a not-for-profit research organization that has studied CO2 utilization and storage for 23 years through projects like Aquistore and Weyburn-Midale. The presentation outline indicates it will cover topics ranging from capture and transport technologies to monitoring CO2 storage sites.