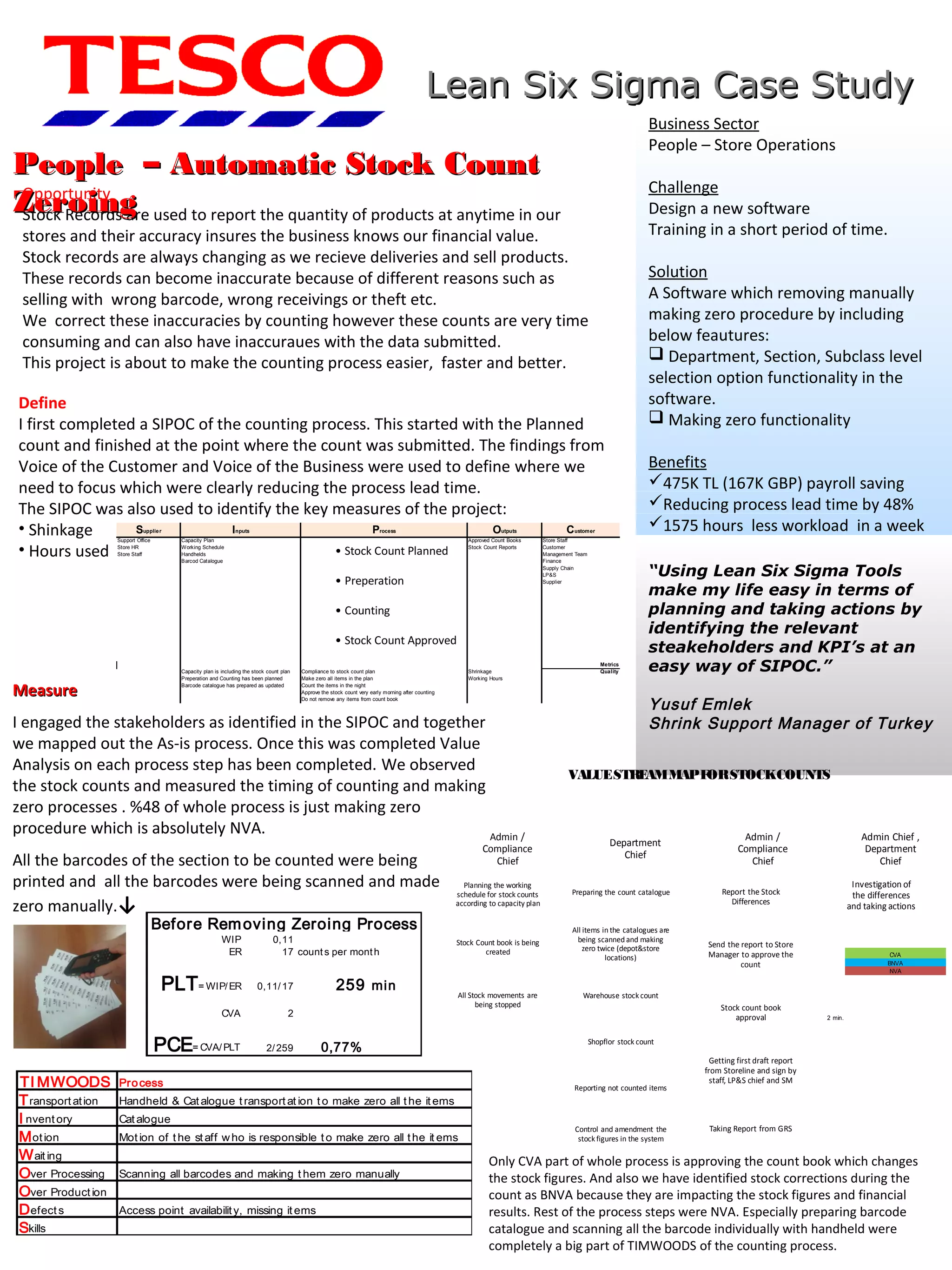

This case study describes a Lean Six Sigma project to improve the stock counting process at a retail company. The goal was to reduce the time spent making zero adjustments during stock counts. Originally, store employees had to manually scan each barcode and make it zero, taking up 48% of the total count time. The team developed software that automated the zeroing process. This reduced the stock count lead time from 259 minutes to 135 minutes. It also improved the process capability from 0.77% to 1.48%. The new process was implemented across all stores, along with training. Compliance reports ensured the automated zeroing tool was being used correctly.