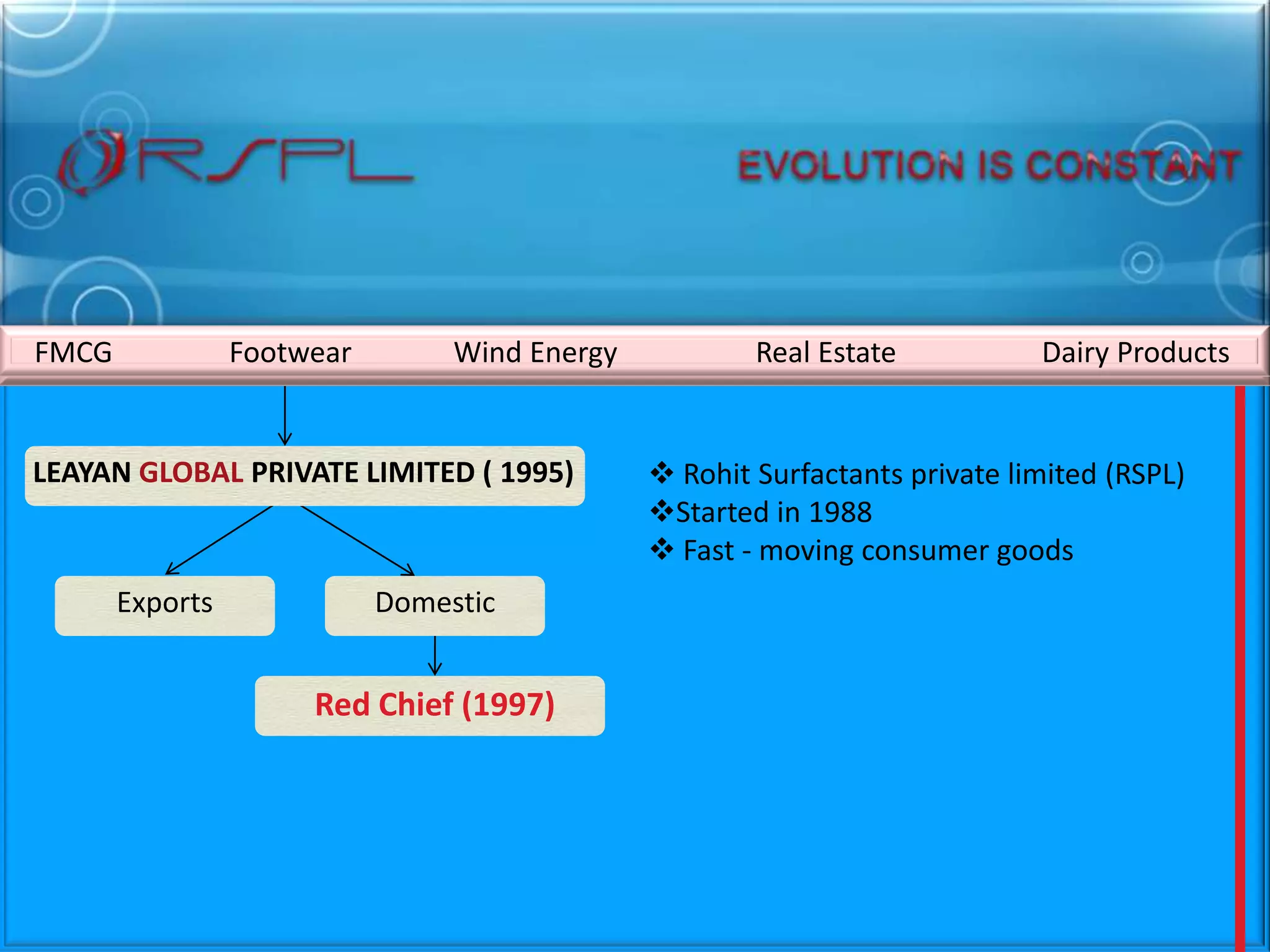

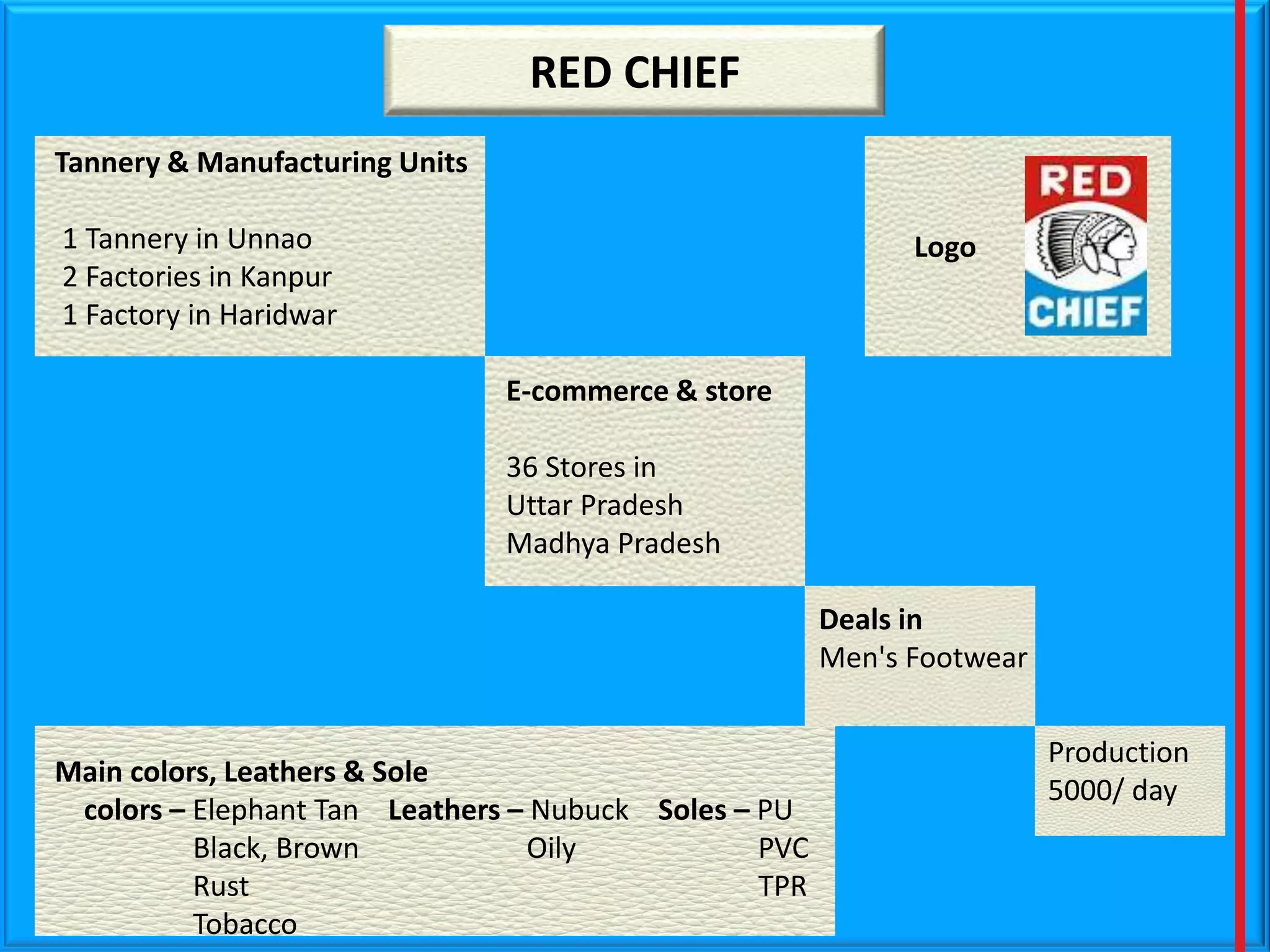

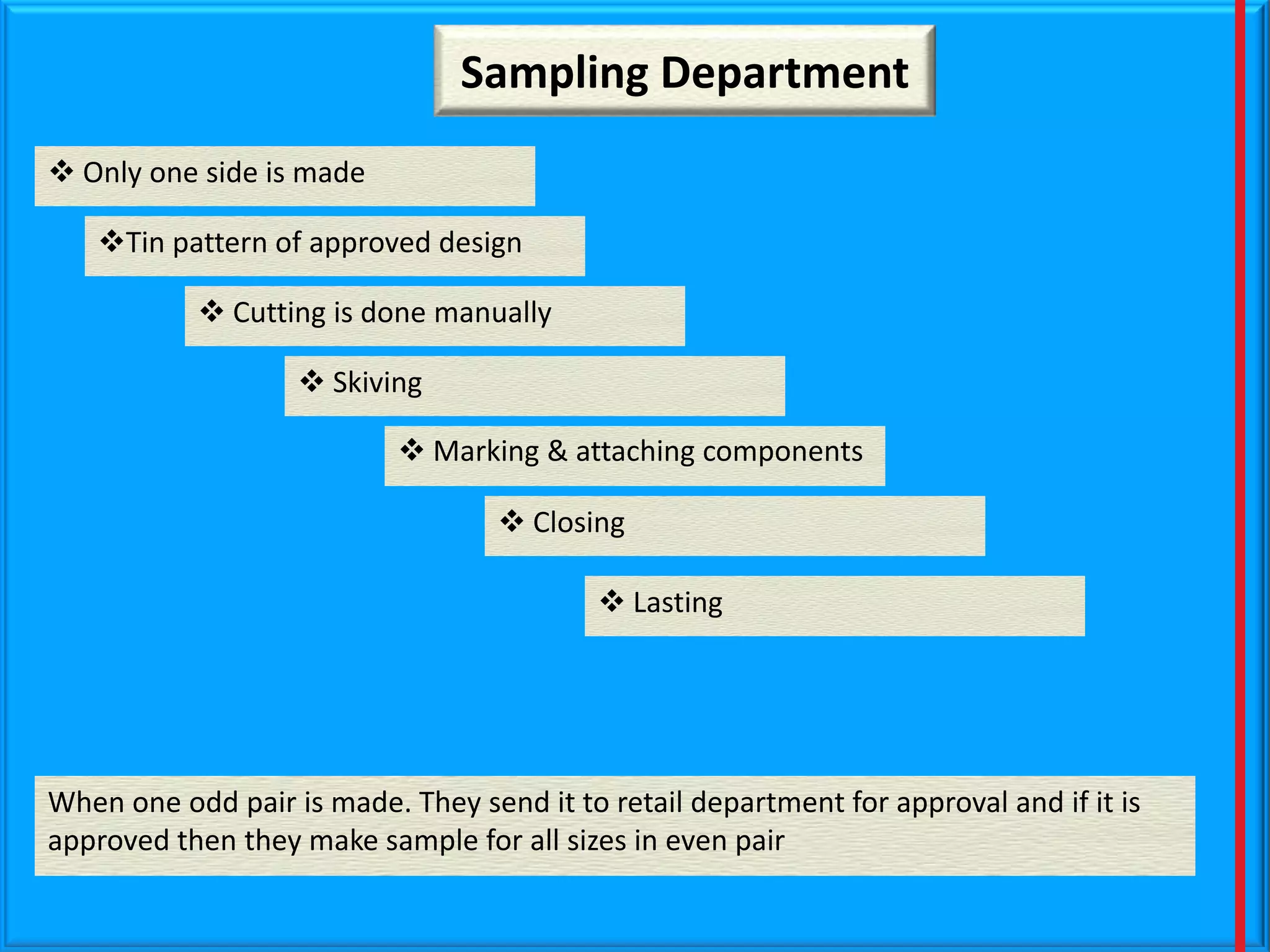

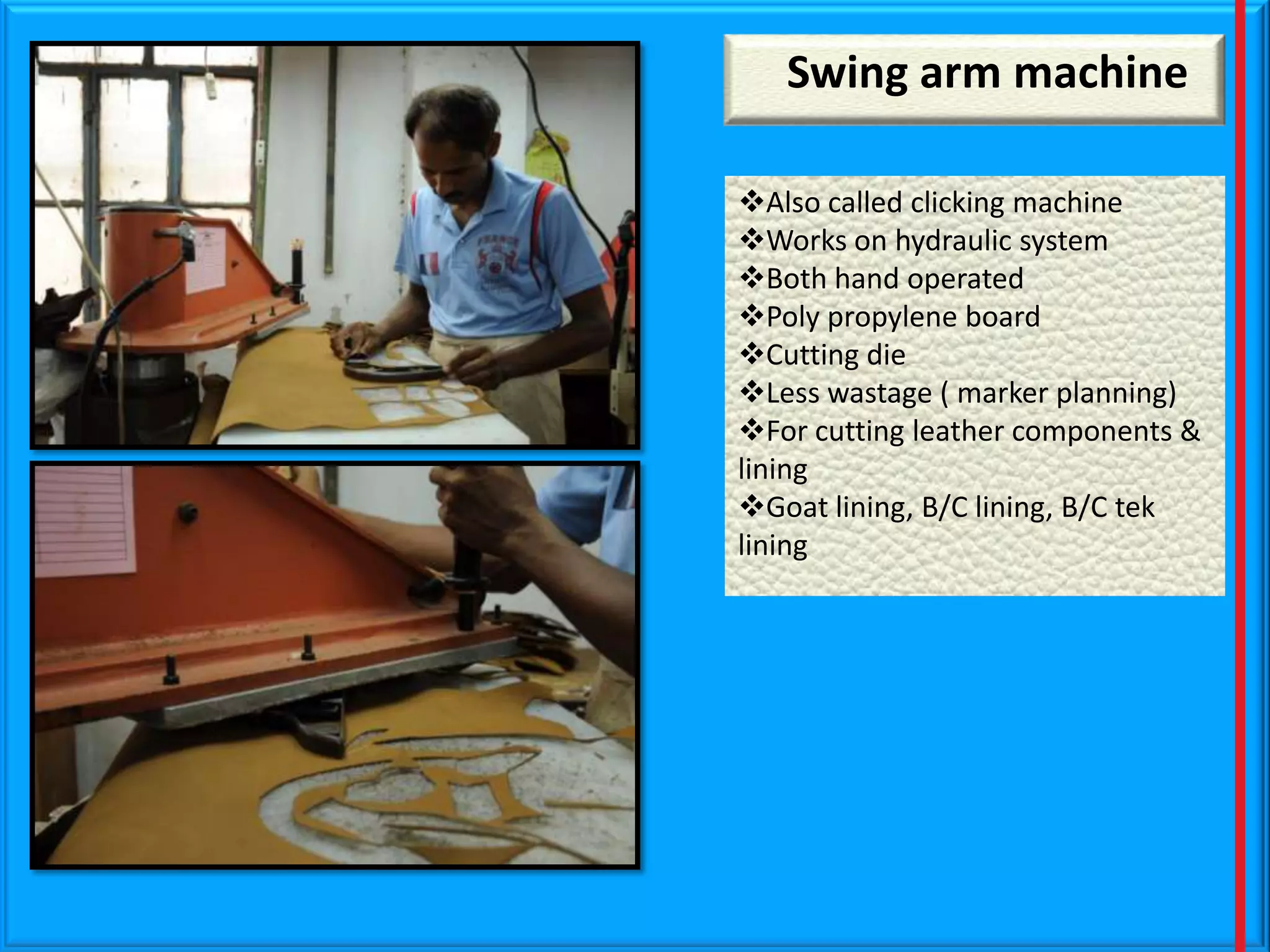

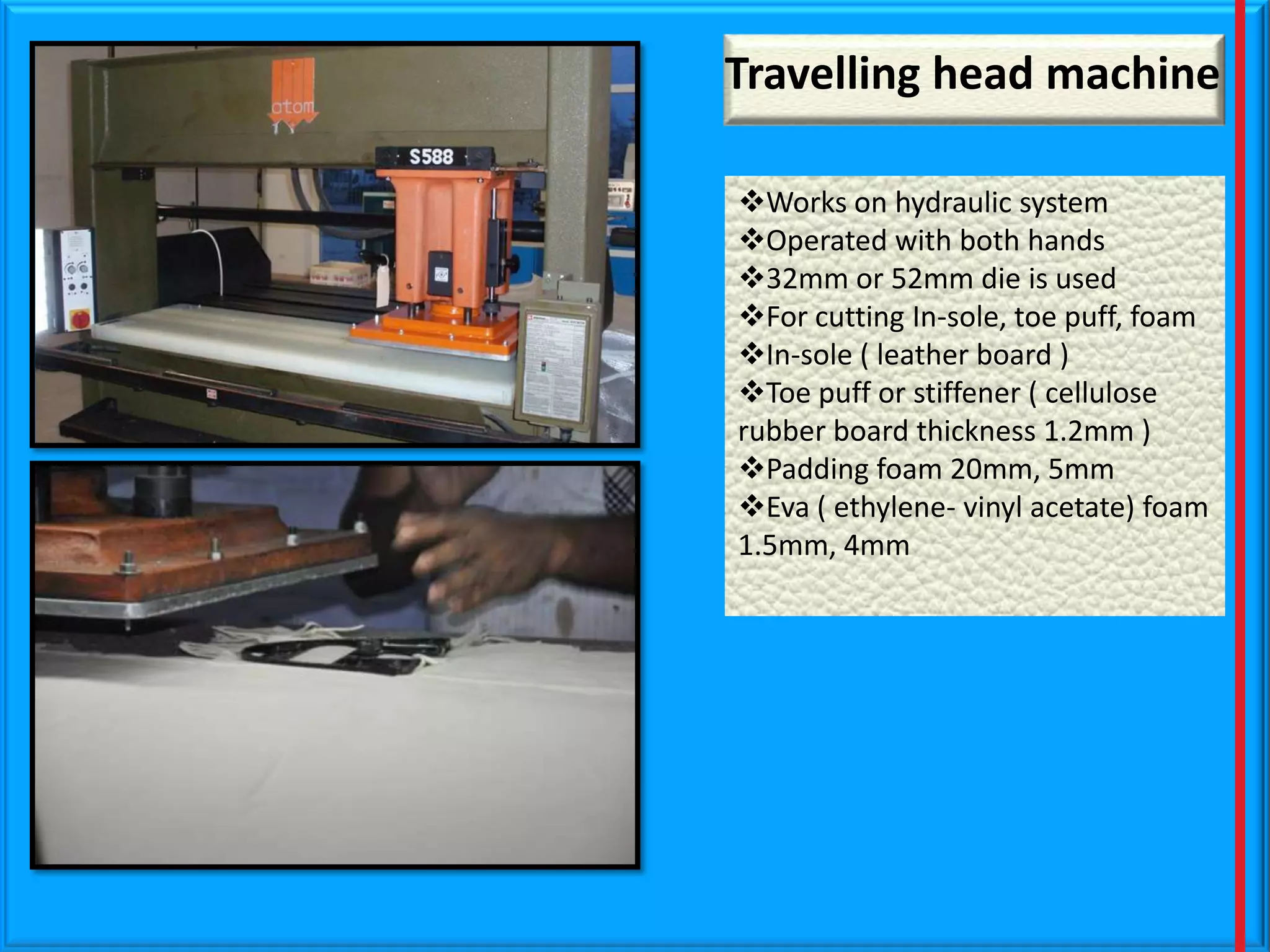

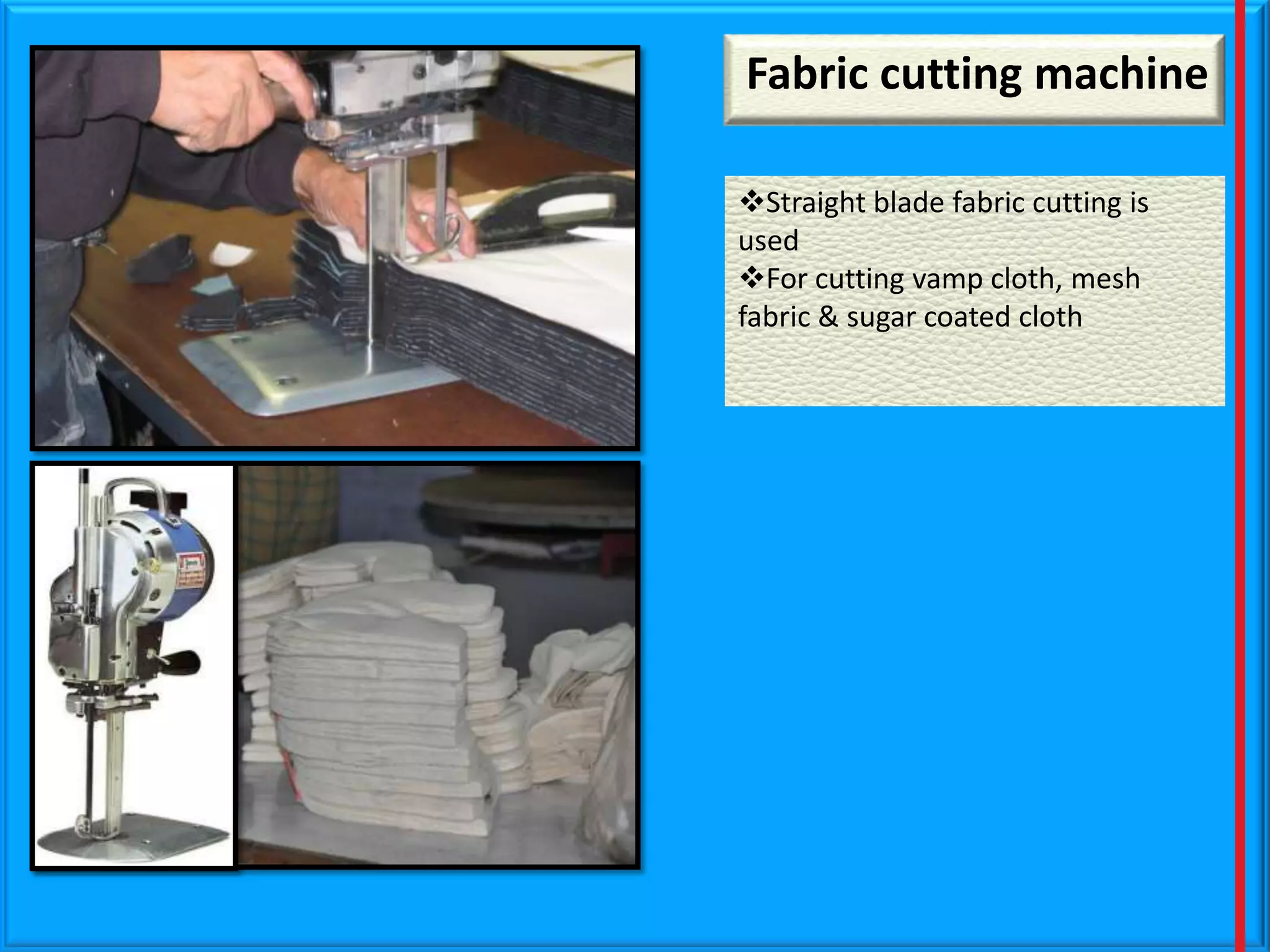

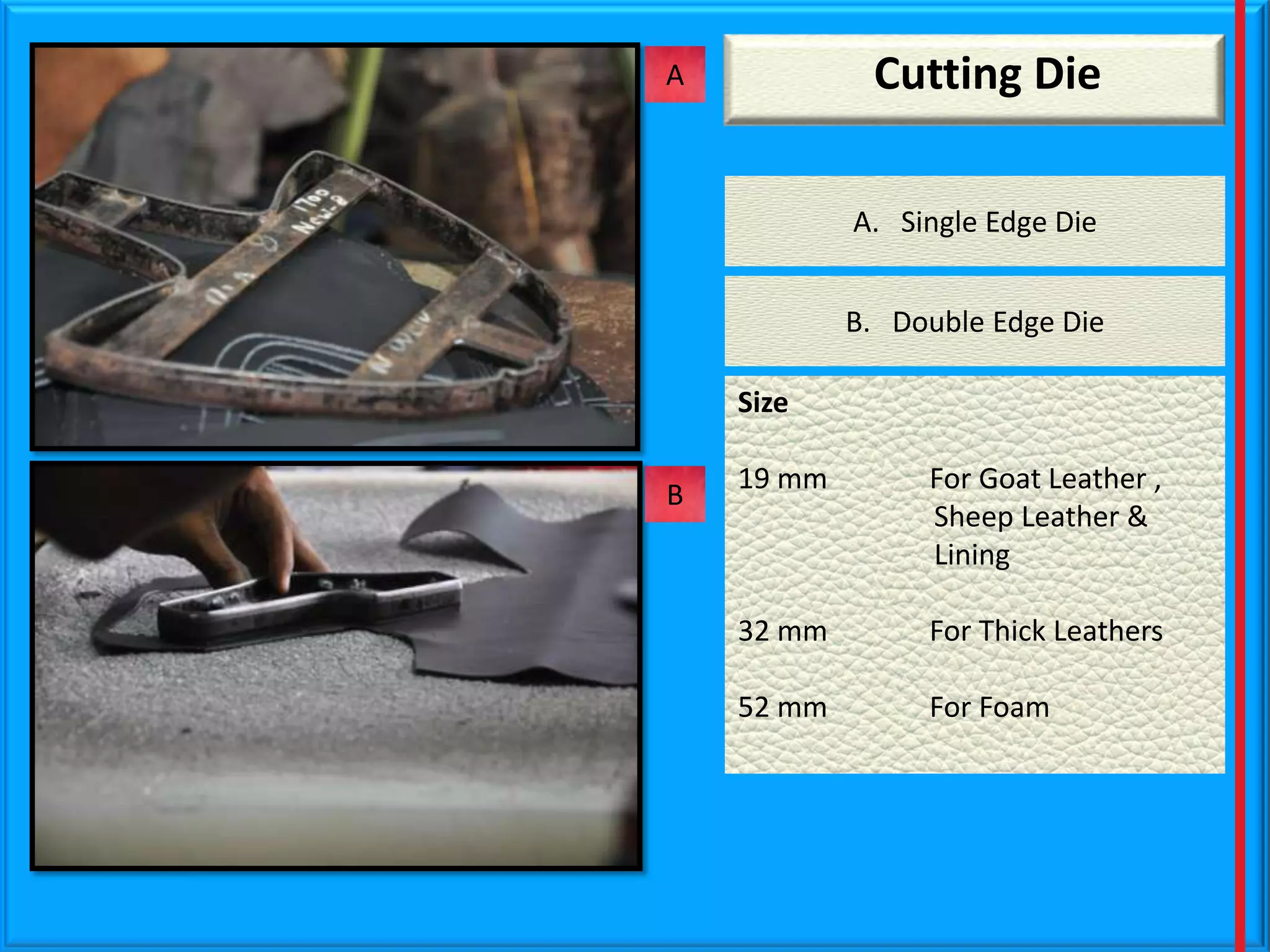

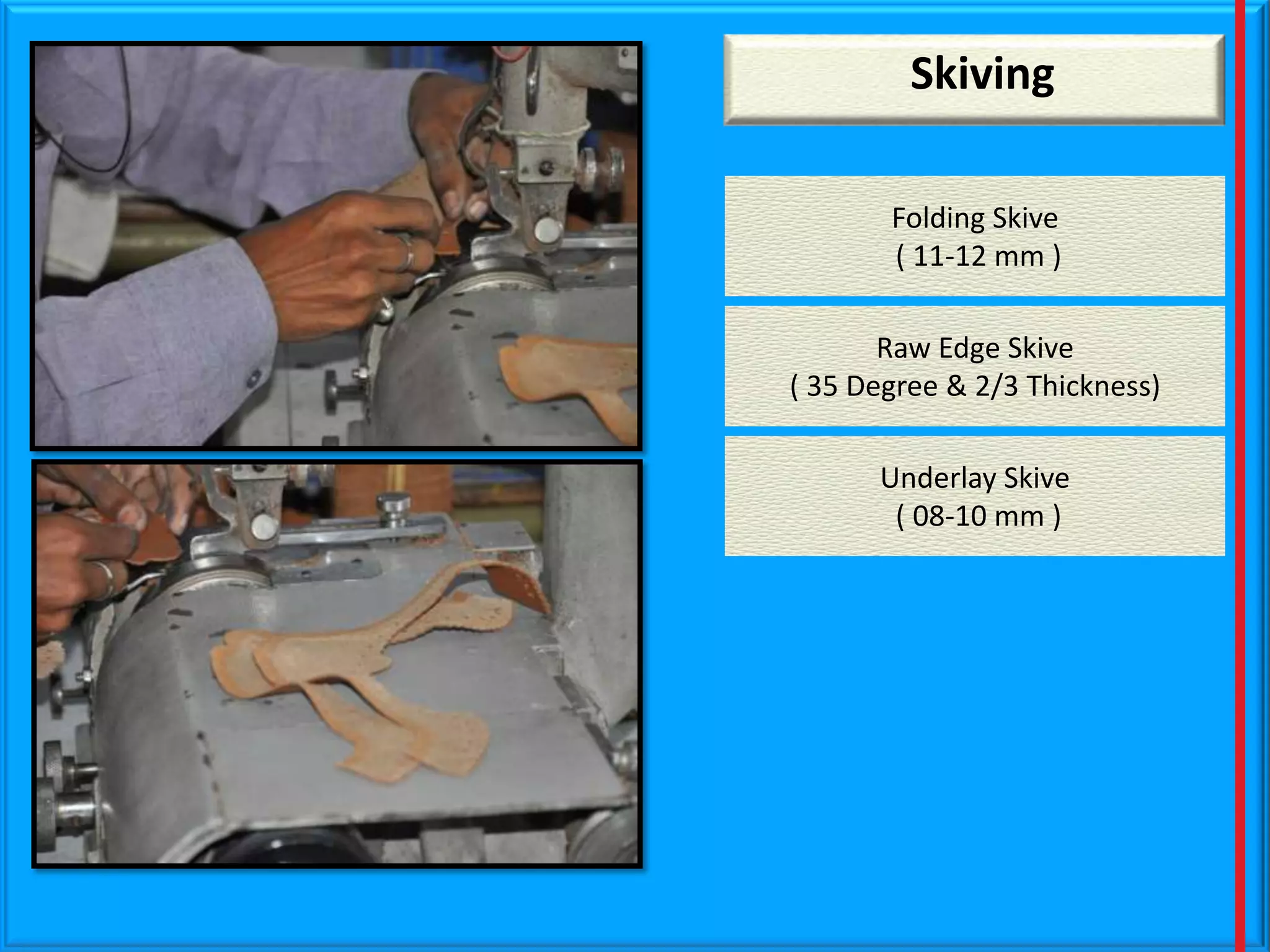

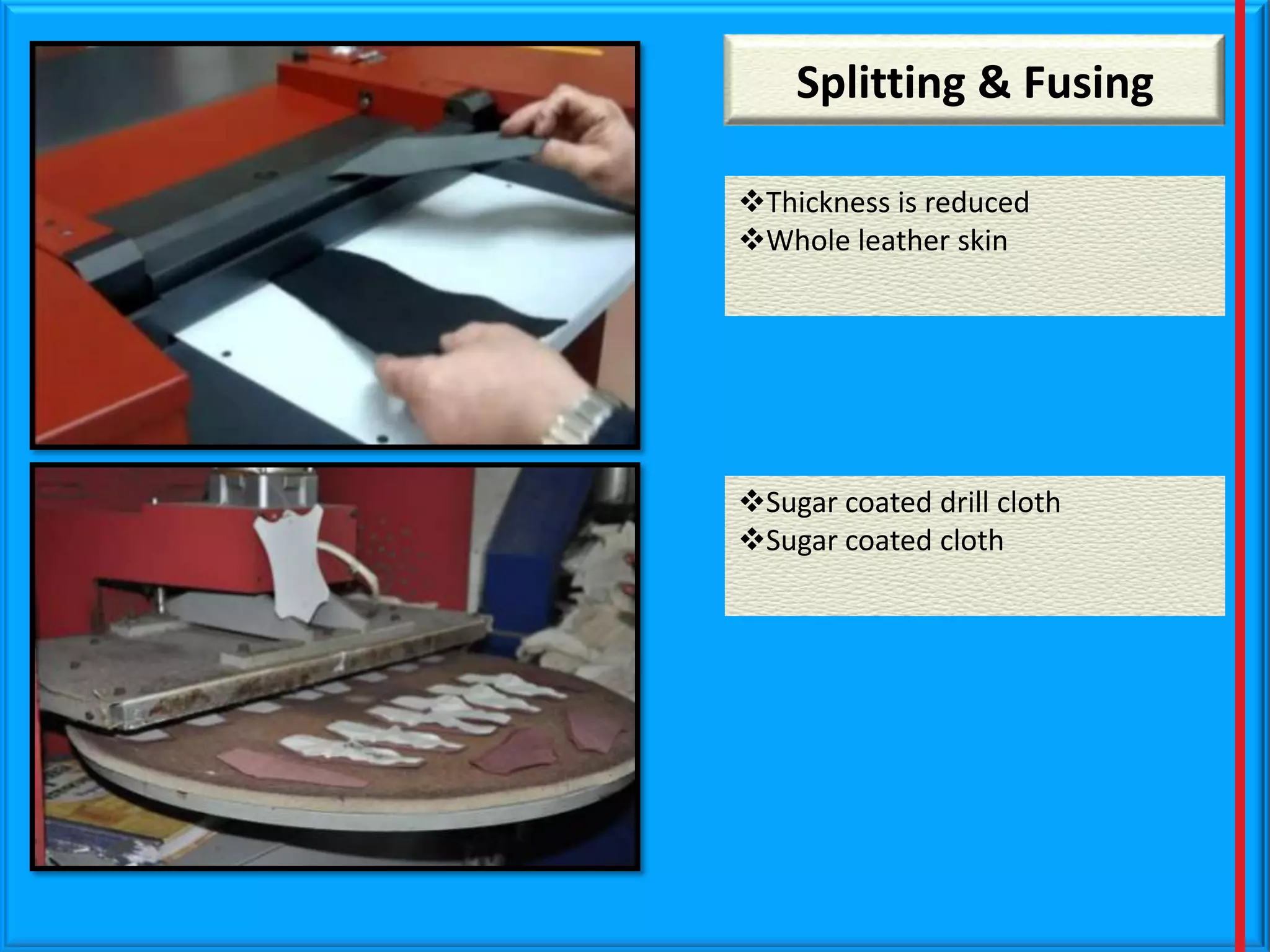

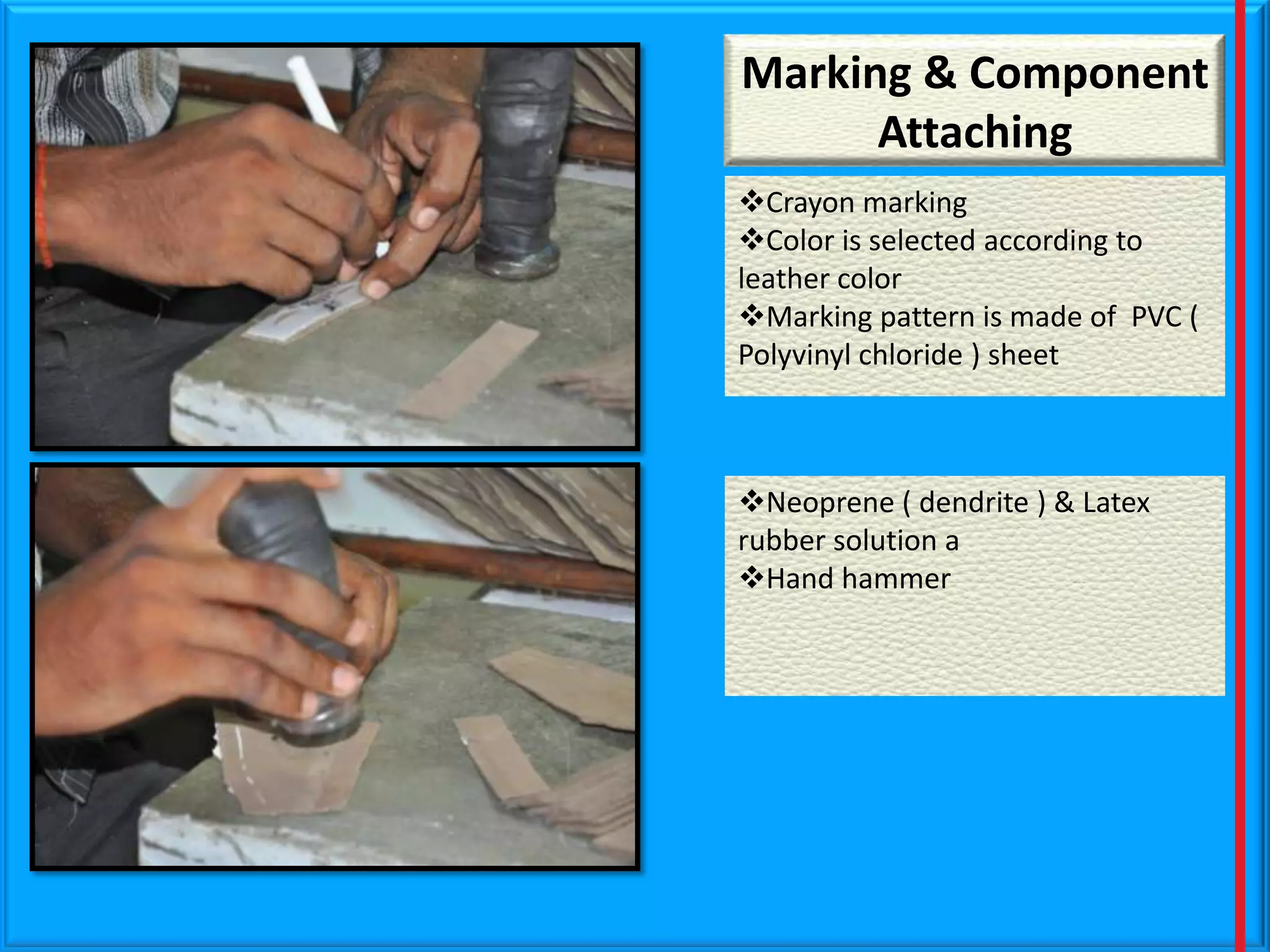

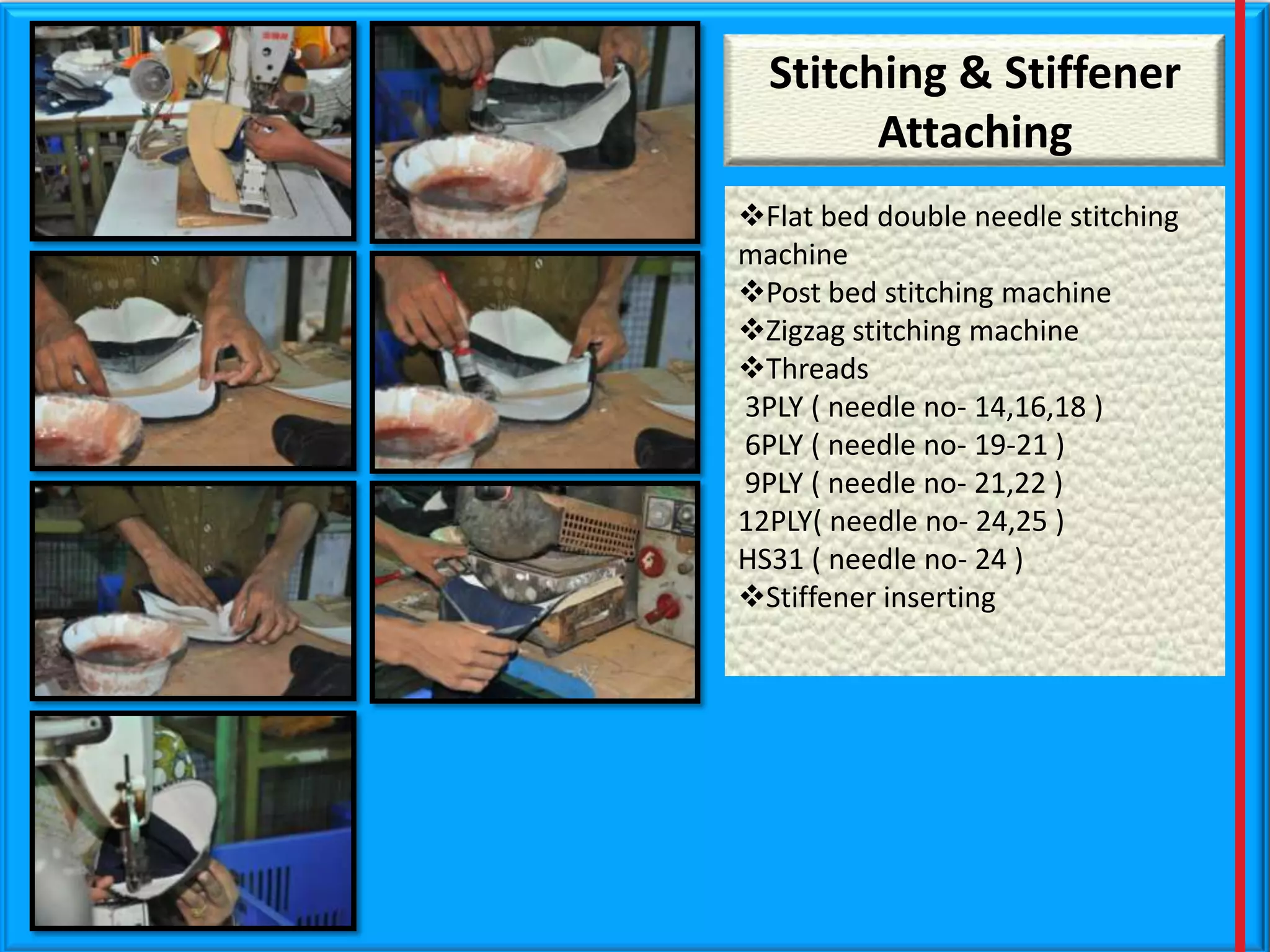

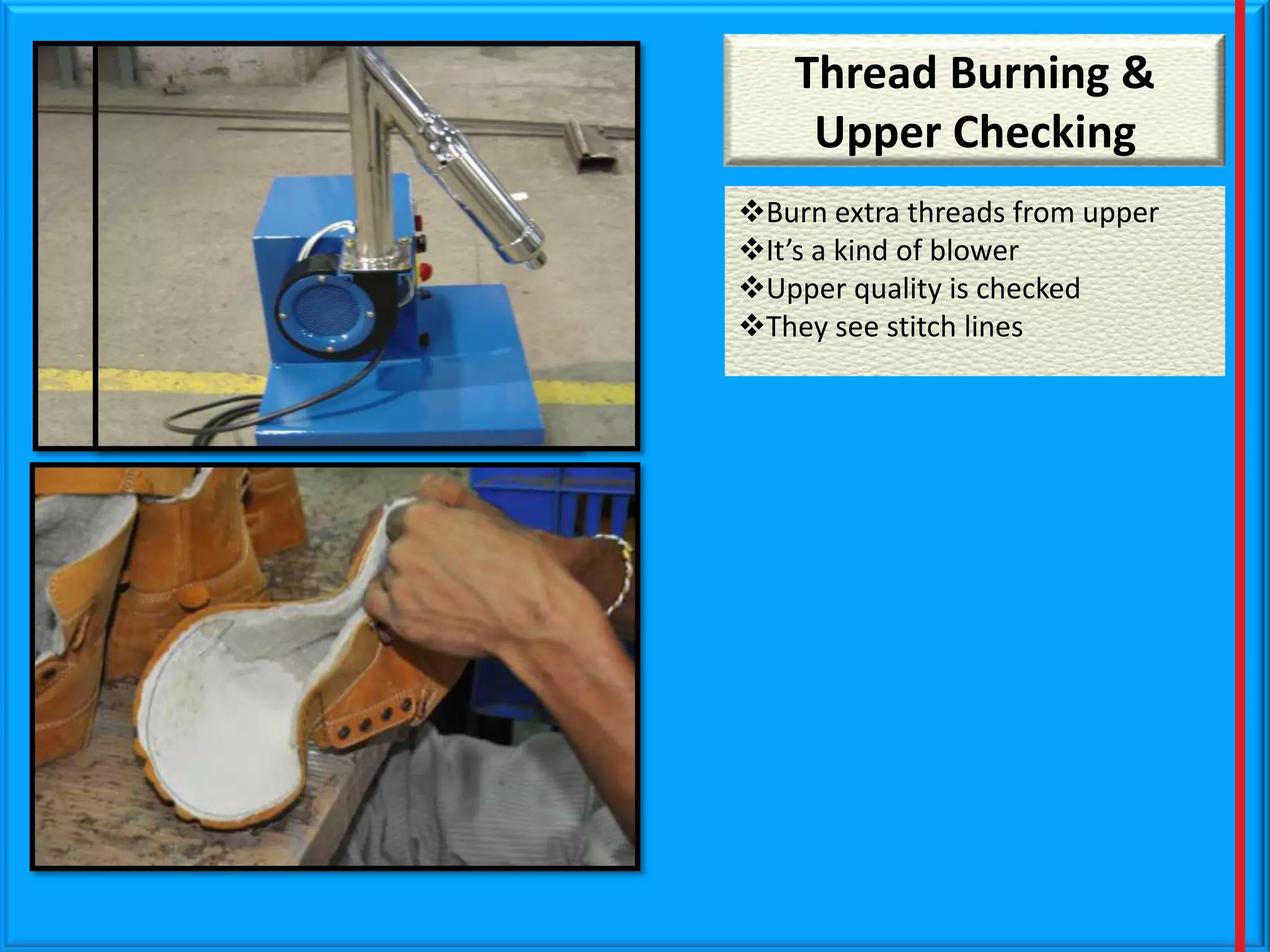

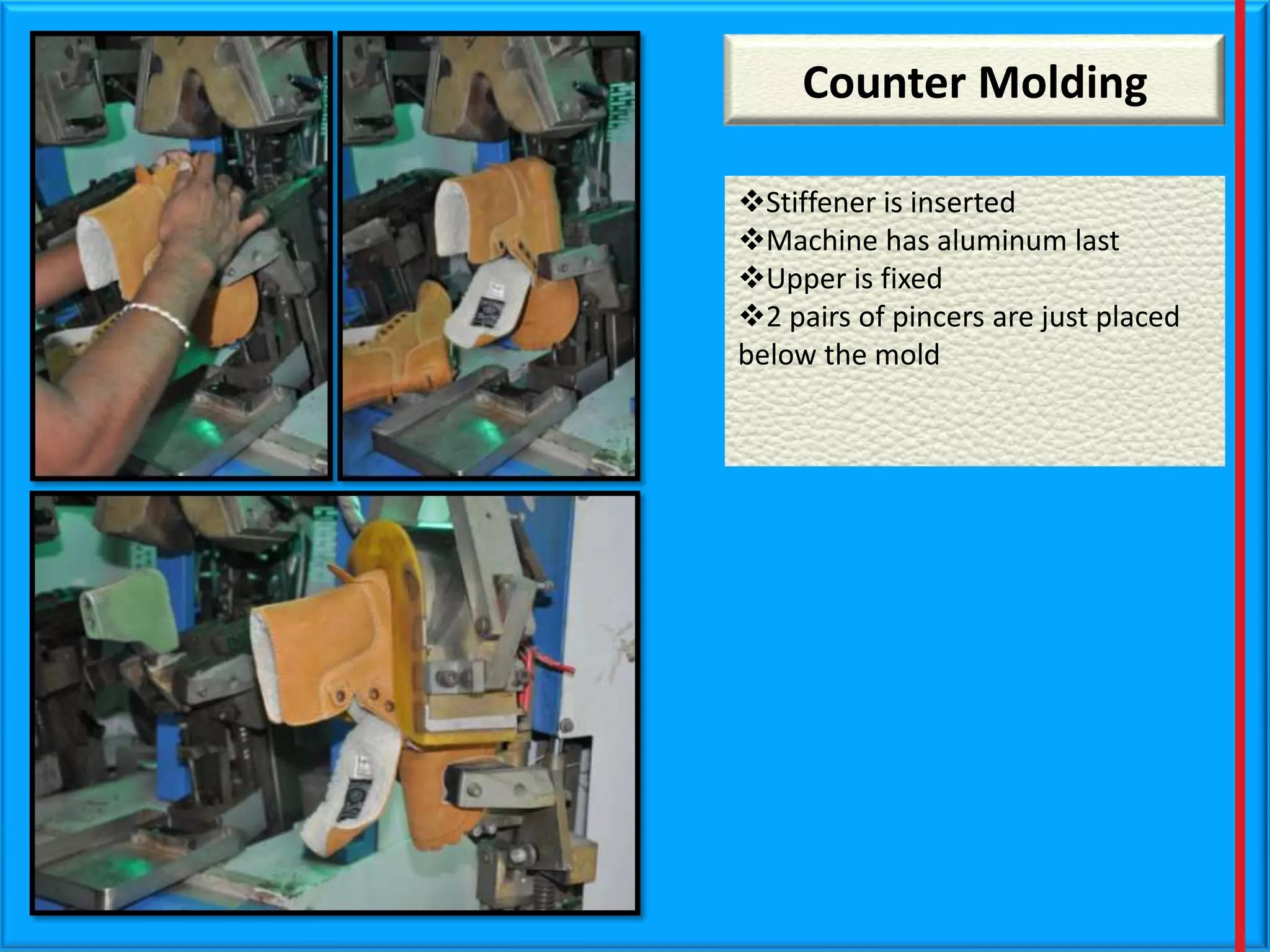

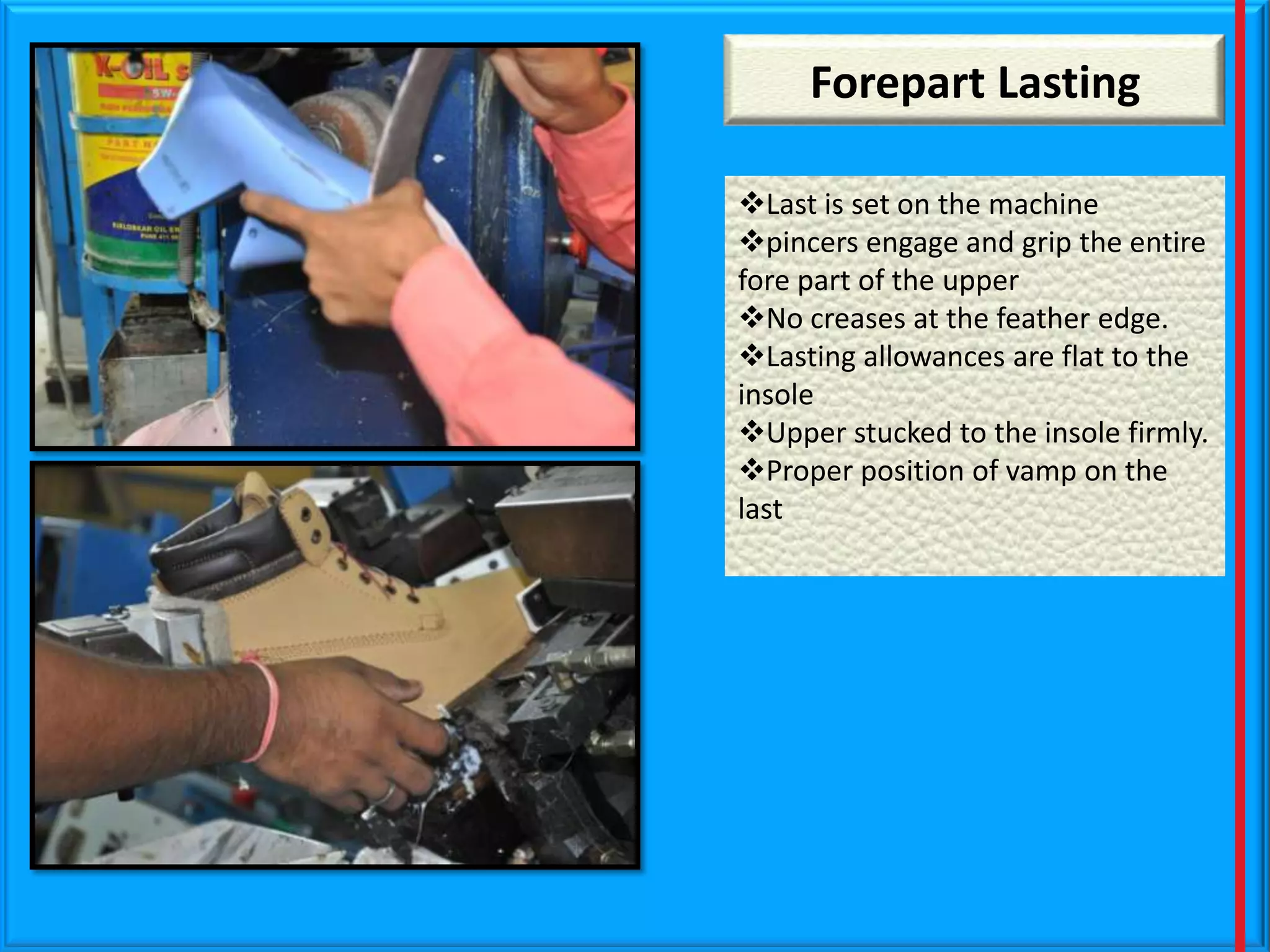

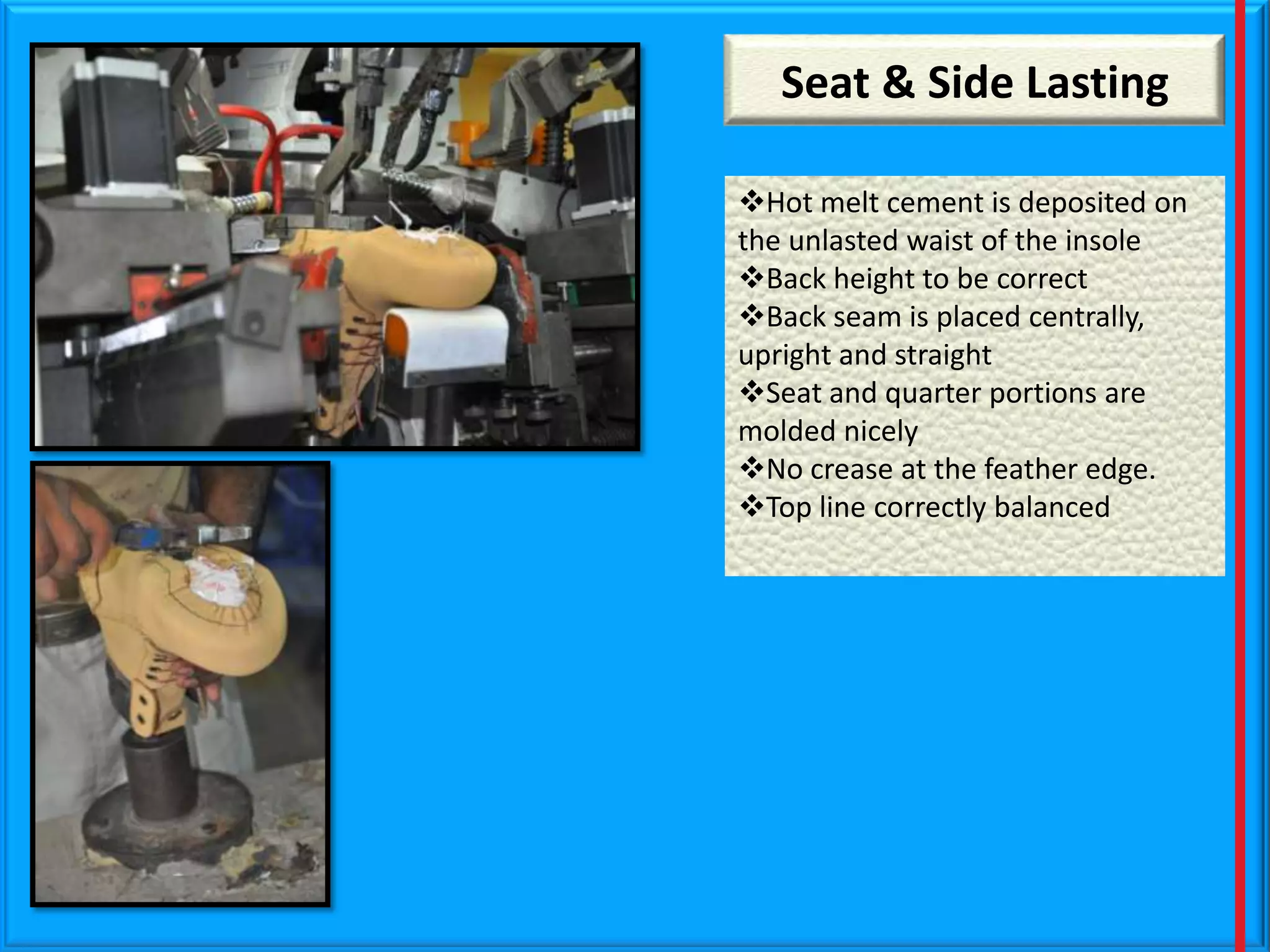

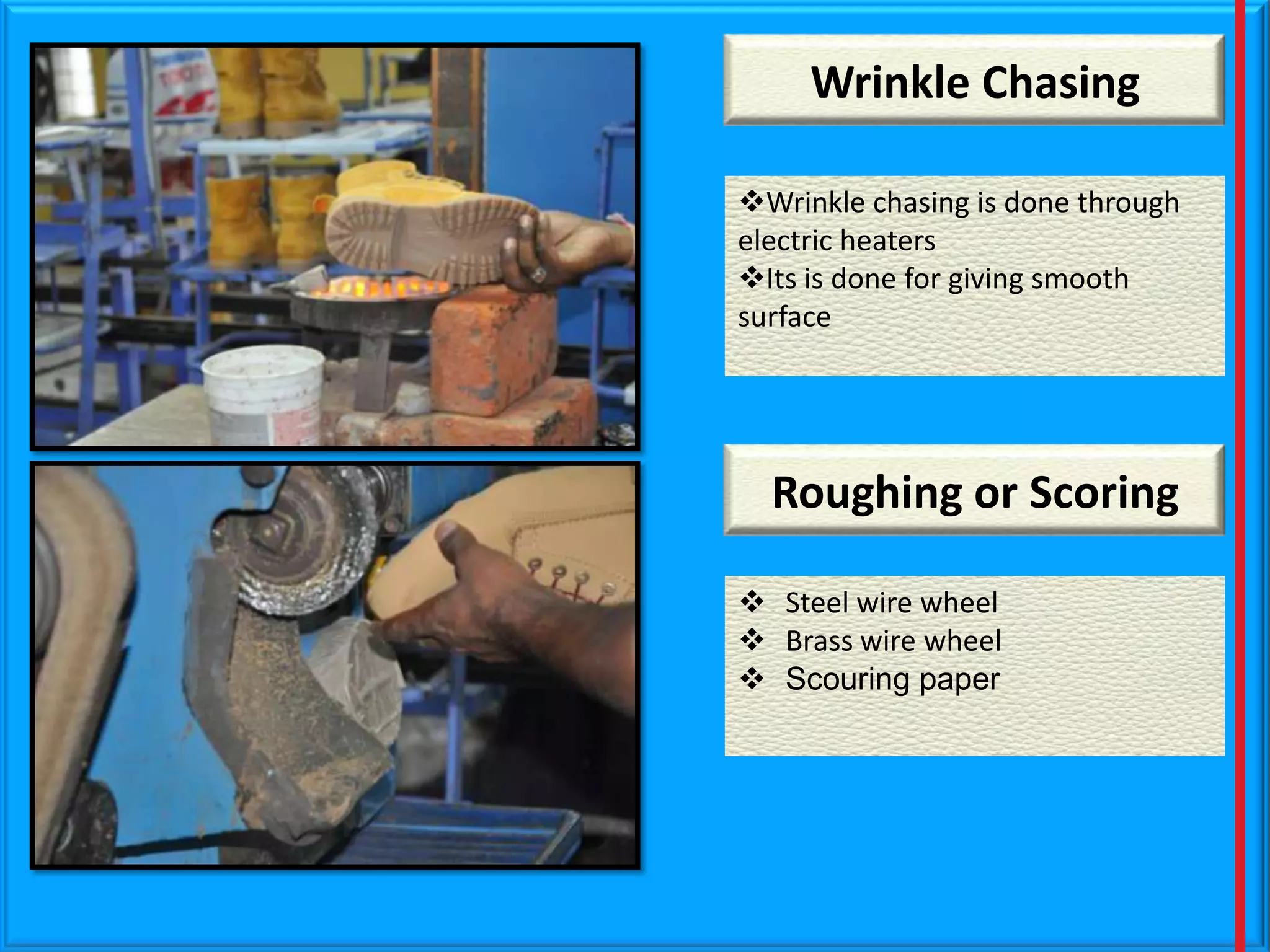

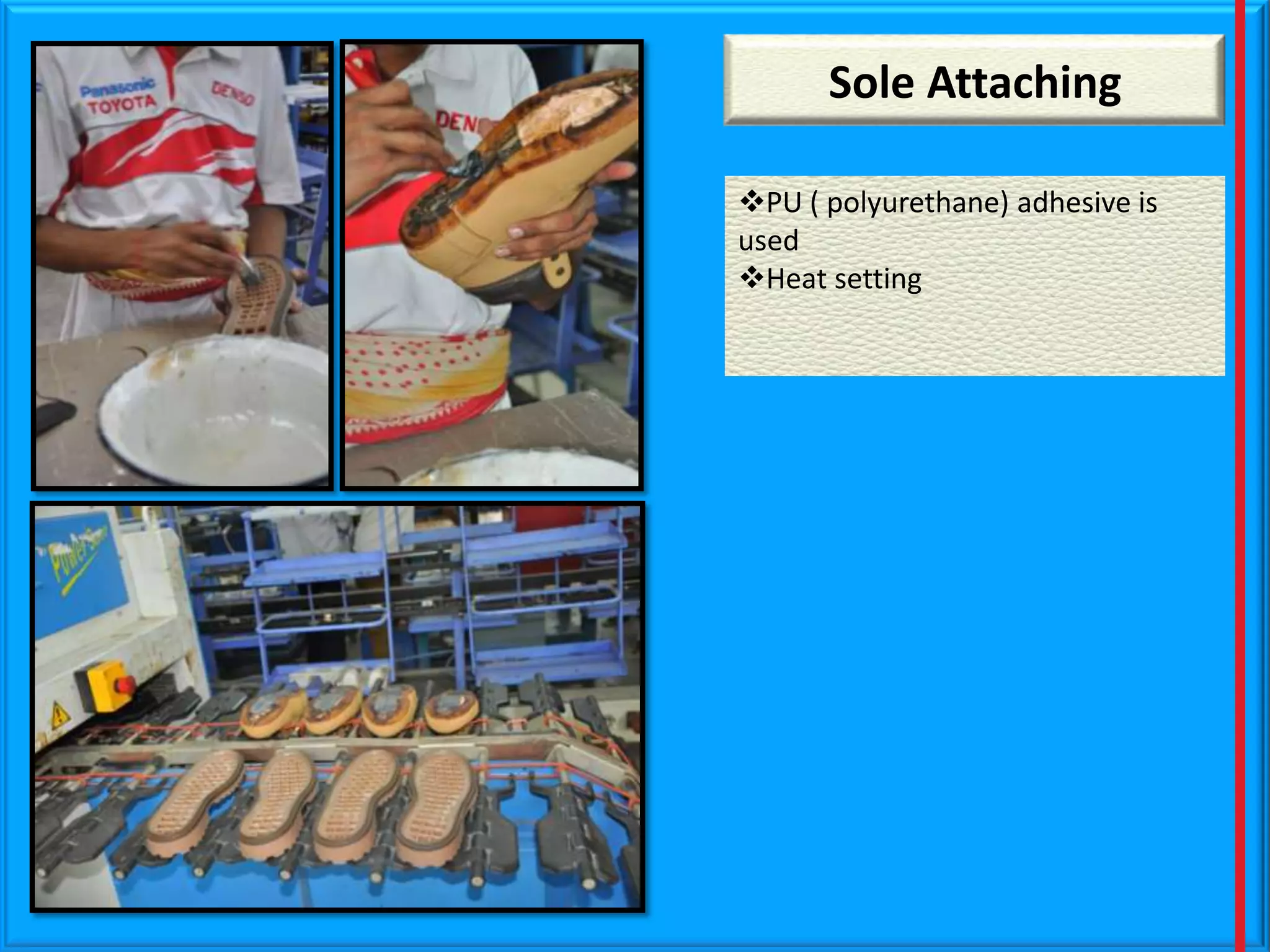

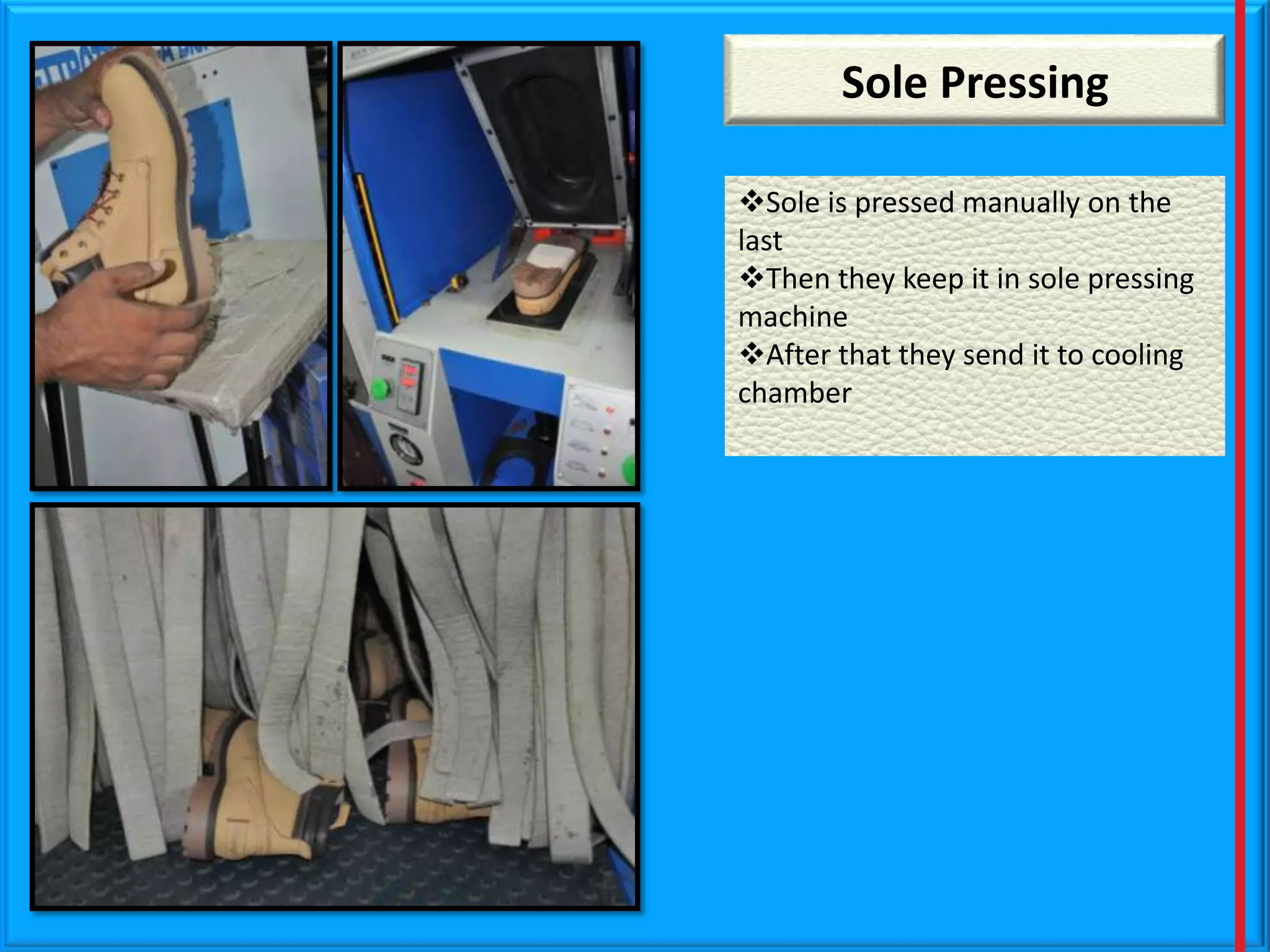

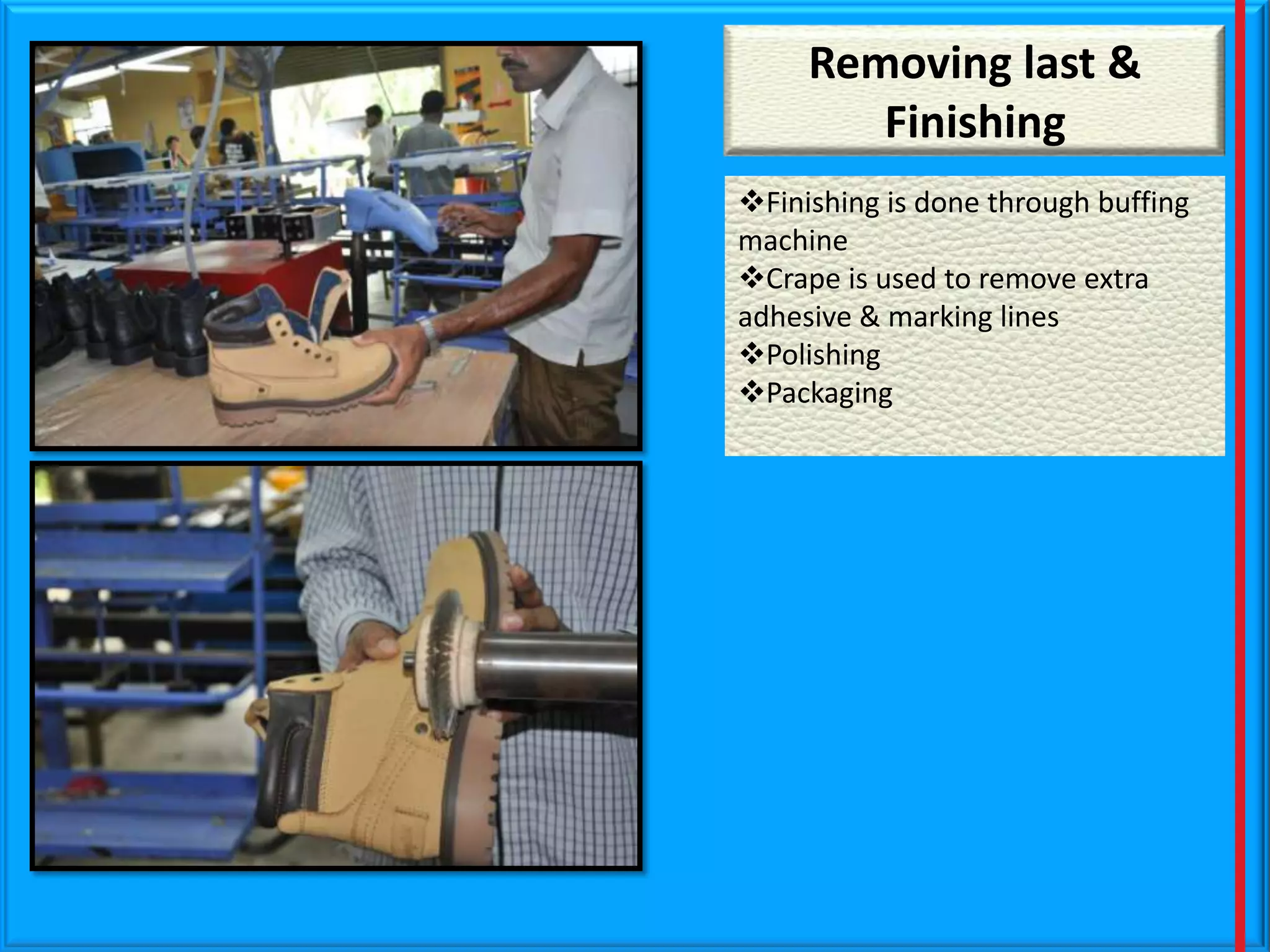

The document provides details about the process of making leather shoes from start to finish at Red Chief, a shoe manufacturing company. It involves many steps: sampling, cutting materials, closing, lasting, sole attaching, finishing. Key processes include cutting leather and other materials using different machines, marking patterns, stitching and attaching stiffeners, molding the upper to the last, attaching the sole, and final polishing and packaging. The student concludes they gained valuable exposure to and understanding of the basics of shoe making through their industrial orientation at Red Chief.