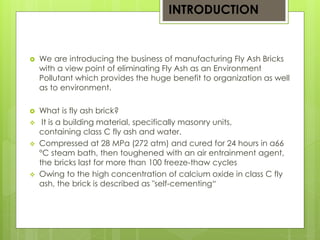

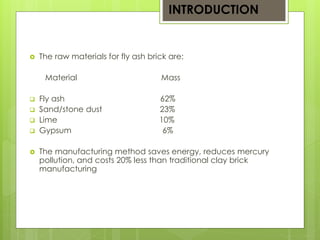

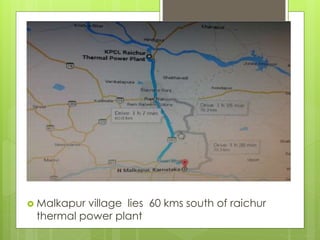

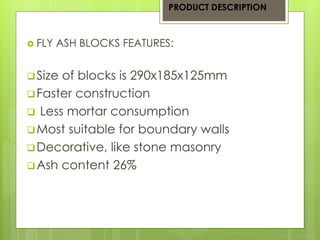

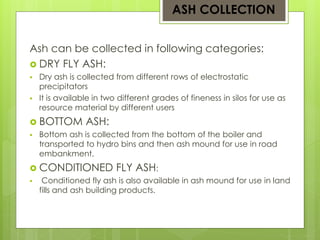

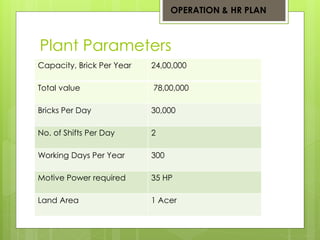

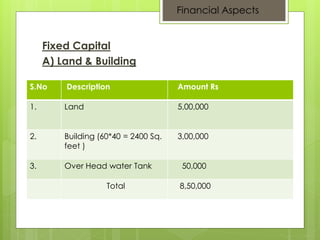

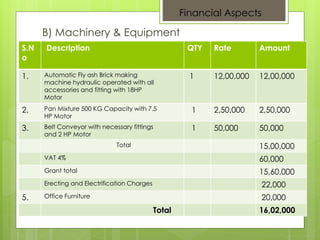

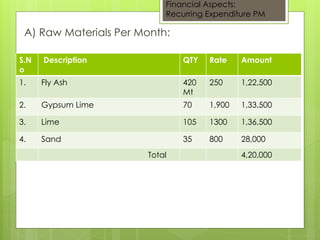

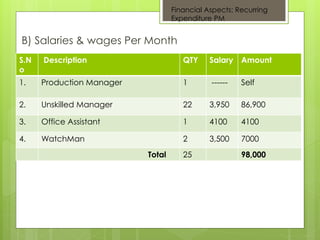

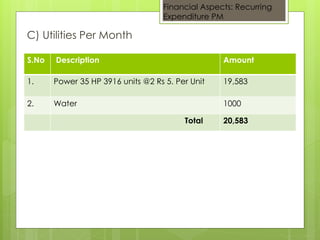

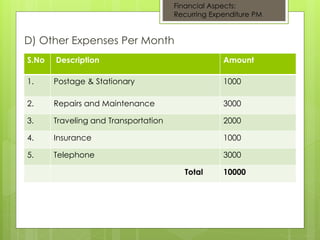

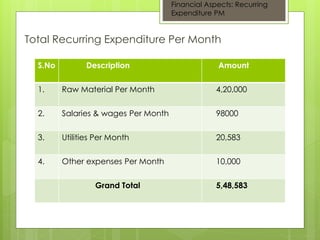

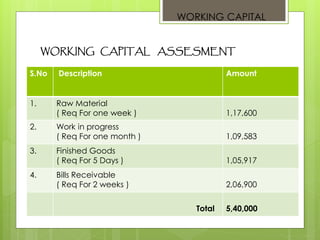

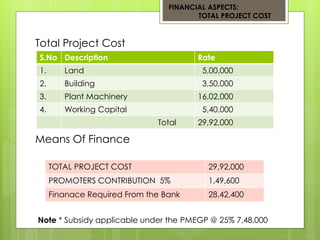

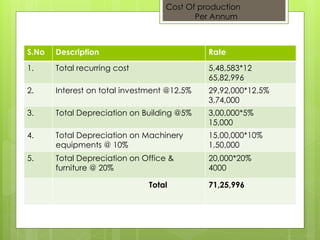

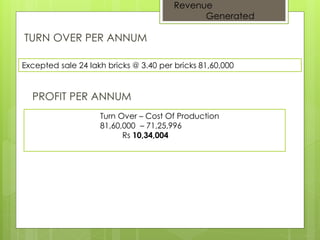

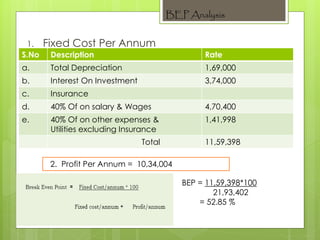

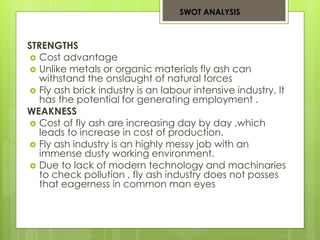

This business plan proposes establishing a fly ash brick manufacturing plant. Fly ash is a byproduct of coal combustion in thermal power plants and currently causes environmental issues. The plan's promoters have MBA and engineering backgrounds. The plant will be located in Raichur district, Karnataka near a thermal power plant and water source. It will employ local villagers and have an annual production capacity of 24 million bricks. The total project cost is approximately 30 lakh rupees to be financed through a bank loan. The plant is expected to be profitable with annual revenues of over 81 lakh rupees and profits of over 10 lakh rupees after covering costs of raw materials, wages, utilities, and depreciation.