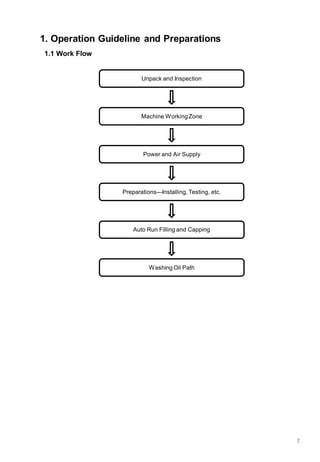

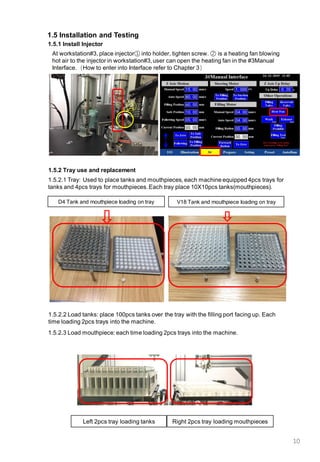

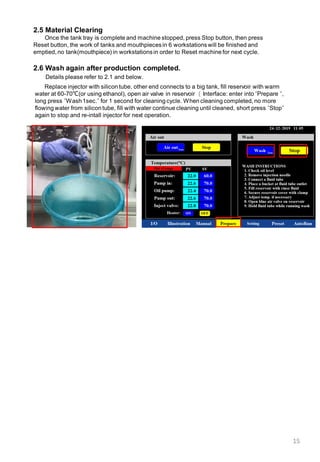

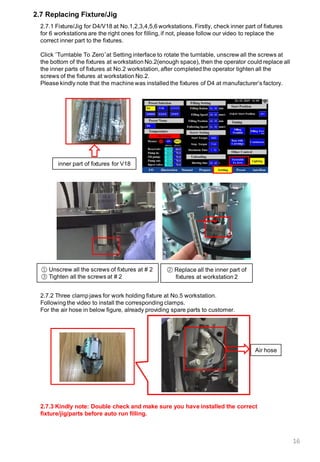

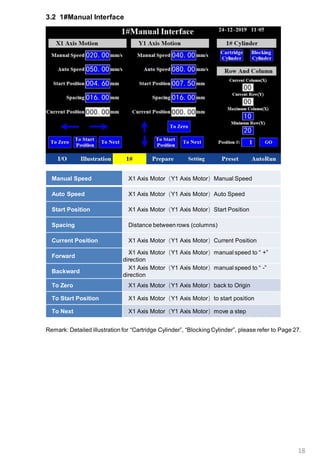

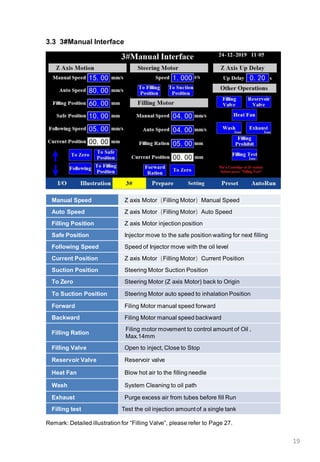

The document provides technical specifications and operation guidelines for a full-auto filling and capping machine, including dimensions, weight, output capacity, and safety precautions. It details setup procedures, operation instructions, maintenance, and troubleshooting measures necessary for safe and efficient machine use. The manual emphasizes adhering to safety standards to prevent potential hazards during operation.