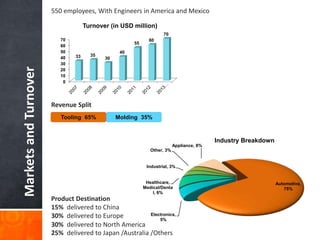

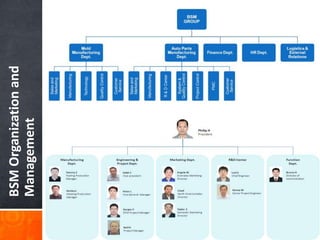

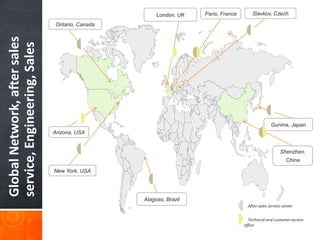

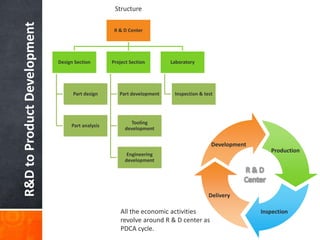

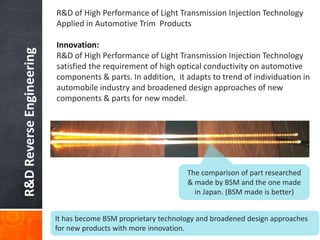

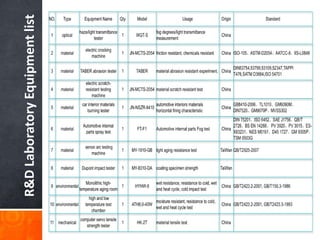

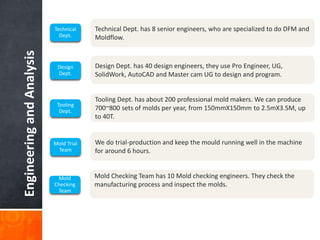

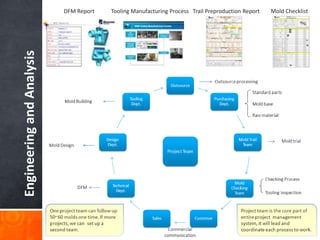

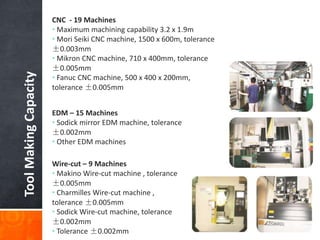

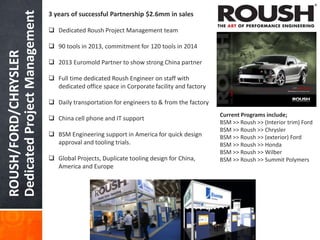

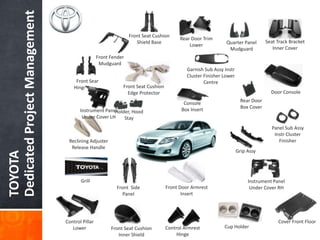

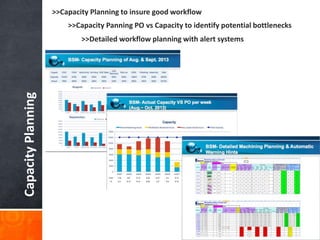

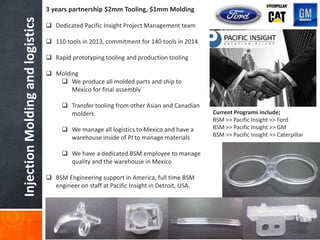

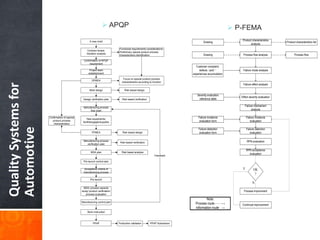

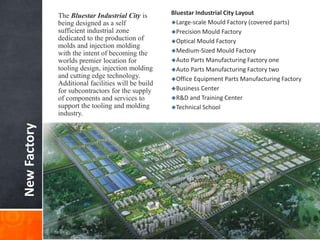

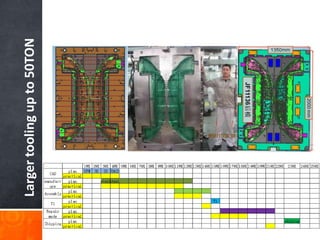

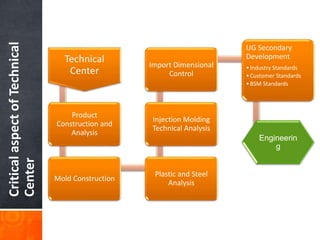

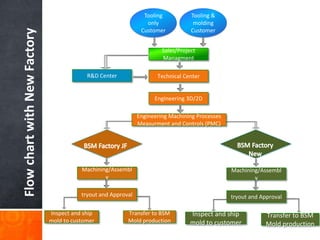

BSM Group, a global manufacturing company, specializes in tooling and injection molding with operations spanning multiple countries and a diverse product portfolio. They focus on R&D for automotive components, utilizing advanced technologies and maintaining rigorous quality and management systems. Future expansions include a new industrial city dedicated to enhancing molding capabilities and automation.