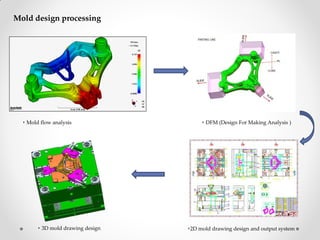

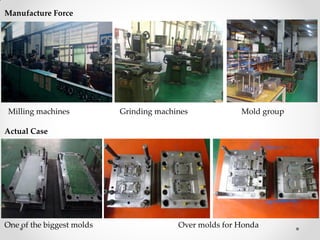

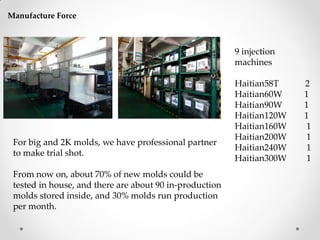

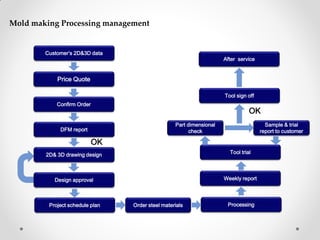

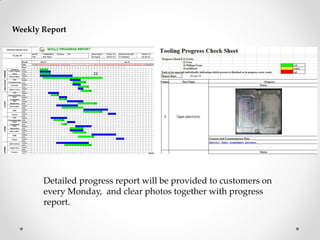

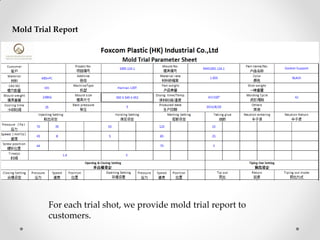

This document summarizes information about a Shenzhen, China-based mold maker called Foxcom Plastic Industrial Company. It was founded in 2008 and focuses on precision injection molds, rapid molds, and other mold types for automotive, electronics, medical, and other industries. The company has over 5400 square meters of space and a team of skilled engineers and CNC/EDM machines to design and manufacture molds. It aims to deliver high-quality molds at competitive prices and provides services from design and prototyping to mass production and after-sales support.