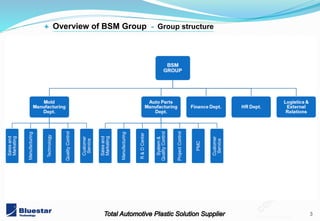

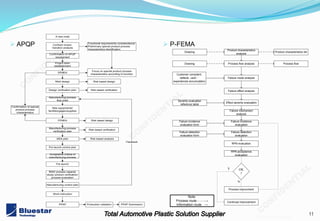

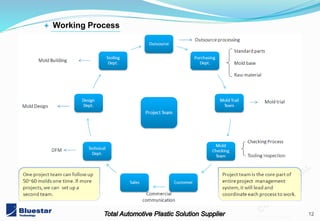

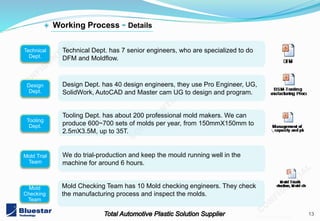

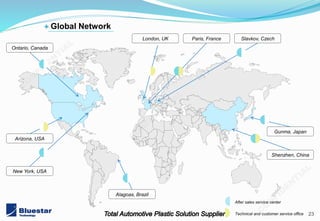

BSM Group, a total automotive plastic solution supplier since 1992, operates globally with 550 employees and reported a turnover of 65 million USD in 2013. The company specializes in tool making, injection molding, and secondary operations, offering a diverse product portfolio mainly focused on automotive components, with major clients across various regions. BSM is committed to quality management, holding certifications including ISO9001, ISO14001, and TS16949, and collaborates closely with research institutions for product development.