The document provides an analysis of the fire protection system at Heriot Watt University in Malaysia. It describes both active and passive fire protection systems. The active system includes smoke detectors, heat detectors, fire alarms, sprinklers and fire extinguishers. The passive system includes fire rated doors, emergency exits, smoke curtains and fire stairs. The document also discusses mechanical ventilation, air conditioning and elevator systems at the university.

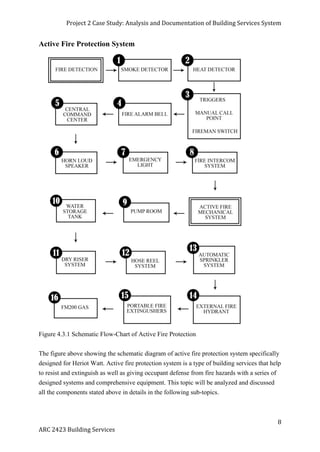

![Project 2 Case Study: Analysis and Documentation of Building Services System

90

ARC 2423 Building Services

7.3 TYPE OF ELEVATOR

Electric elevator [Machine-room-less (MRL) traction]

Figure 7.3.1 Photos of Elevators in Heriot Watt University, Malaysia.

The Machine Room-Less (MRL) elevator is now available because advanced motor

technology has reduced the size of electric motors used with traction equipment. These newly

designed permanent magnet motors (PMM) allow the manufacturers to locate the machines

in the hoistway overhead, thus eliminating the need for a machine room, typically over the

hoistway. A typical traction elevator requires a sheave-to-rope ratio of 40:1 – in other words,

a sheave 40 times the diameter of the hoist rope. Smaller ratios such as 16:1 might be

achieved with the MRL hoisting methods. When these types of smaller ratios are achieved, a

flexible high strength hoist rope is used to provide the smaller 16:1 ratio. The grooves are

shaped to grip the hoist ropes.](https://image.slidesharecdn.com/bservicereport2-151213202145/85/Bservice-report-91-320.jpg)