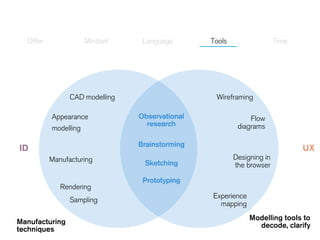

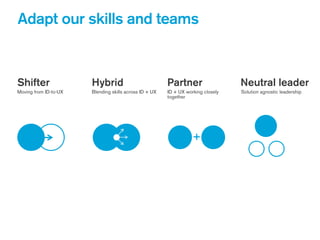

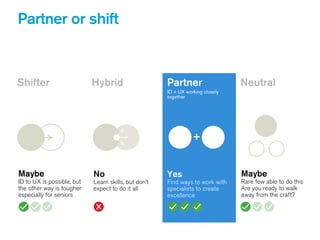

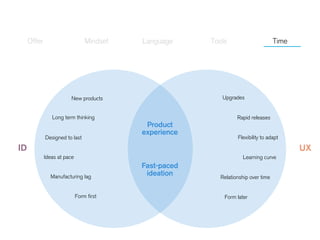

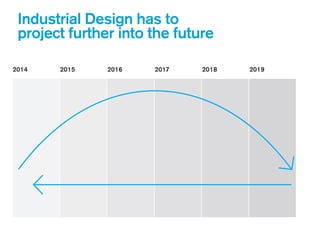

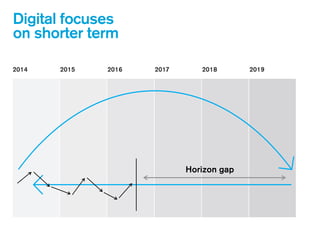

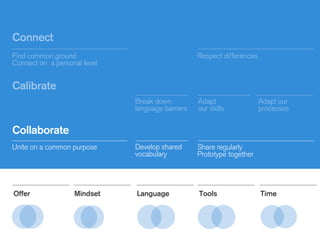

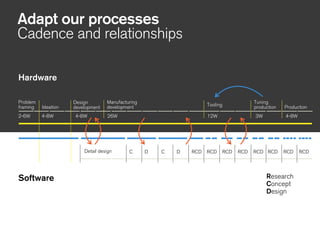

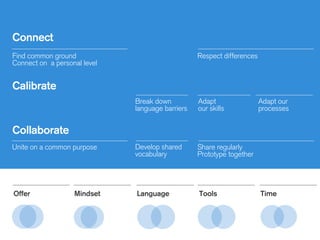

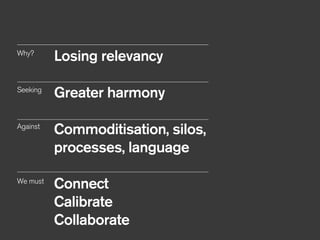

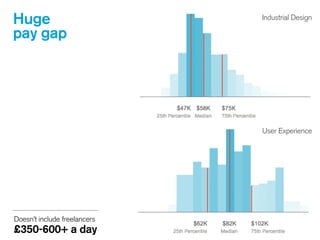

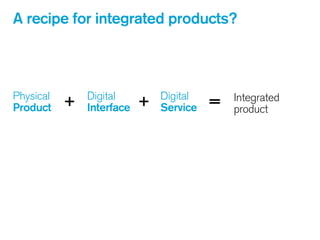

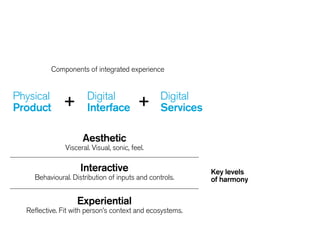

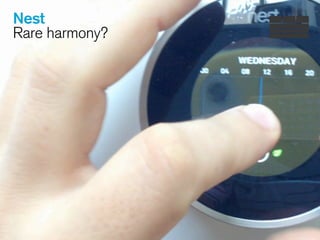

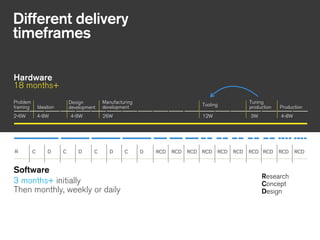

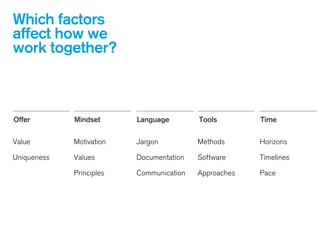

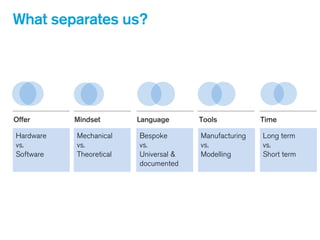

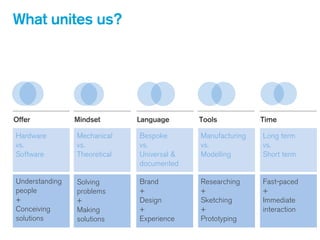

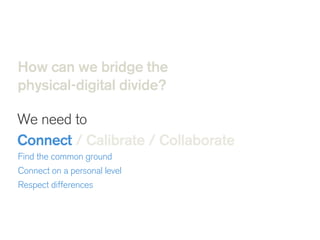

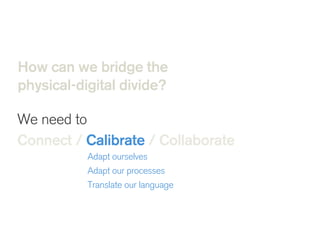

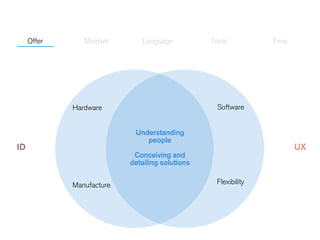

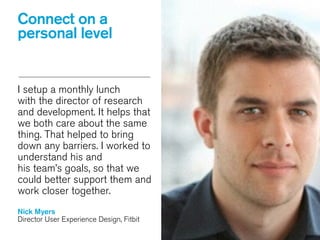

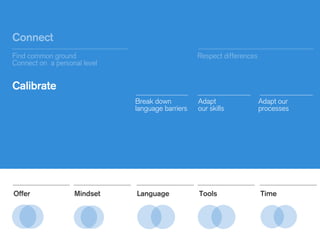

The document discusses the need for integration between industrial design and user experience (UX) to create harmonious physical-digital products. It highlights challenges such as commoditization, delivery differences, and separation of teams, which hinder collaboration. To bridge the gap, it advocates for connecting, calibrating, and collaborating across disciplines to foster better product development and innovation.

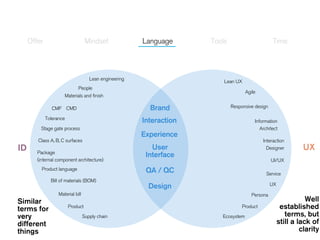

![Language

IDers often say they don’t

understand [UX], but shifting

perspective and language

helps them realise when

they are doing it. As a way to

bridge the gap, I'd often look

at their past work, point to

the solutions that worked

well and relate it to [UX].

!

Kim Lenox

Former User Experience Director, Lunar](https://image.slidesharecdn.com/bridgingthephysical-digitaldividejasonmesut-140729101244-phpapp02/85/Bridging-the-Physical-Digital-Divide-Jason-Mesut-106-320.jpg)