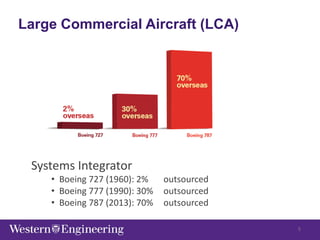

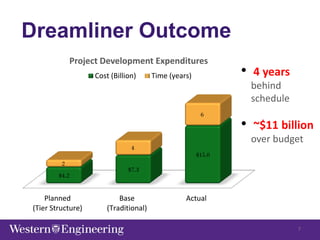

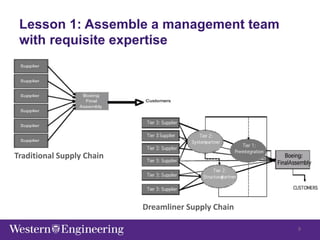

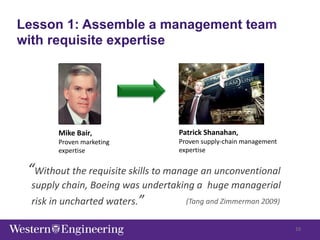

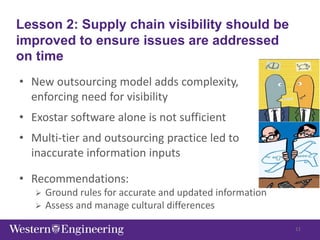

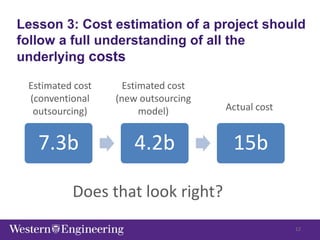

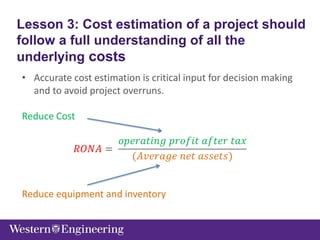

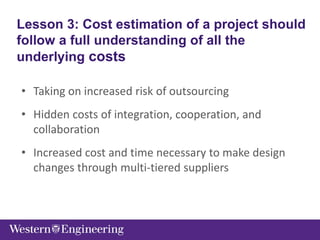

The document provides a case study on the lessons learned from Boeing's 787 Dreamliner project. It summarizes that Boeing aimed to cut costs and development time through an unconventional supply chain model where 70% of the work was outsourced. However, this resulted in the project being over budget by $11 billion and 4 years delayed. Key lessons identified include: assembling a management team with supply chain expertise, improving supply chain visibility, fully understanding all underlying project costs before estimating, improving supplier training and selection processes, proactively managing labor unions, and implementing risk-sharing contracts with incentives and penalties for partners.