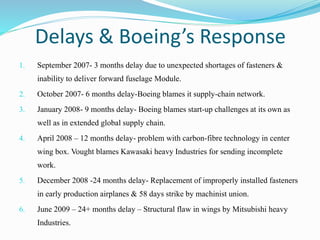

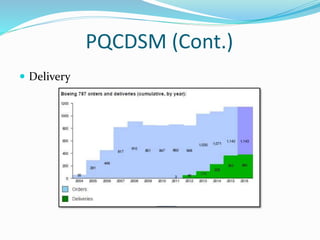

Boeing founded in 1916 is the world's largest aerospace company with two main businesses of commercial airplanes and defense. In the late 1990s/early 2000s, Boeing merged with competitors and unveiled a new vision. It announced the 787 Dreamliner in 2003 to compete with Airbus' A380 superjumbo, which saw delays until first delivery in 2011 due to issues with suppliers and new composite materials. Boeing responded by promoting collaboration with partners and developing new monitoring tools to better integrate production globally.