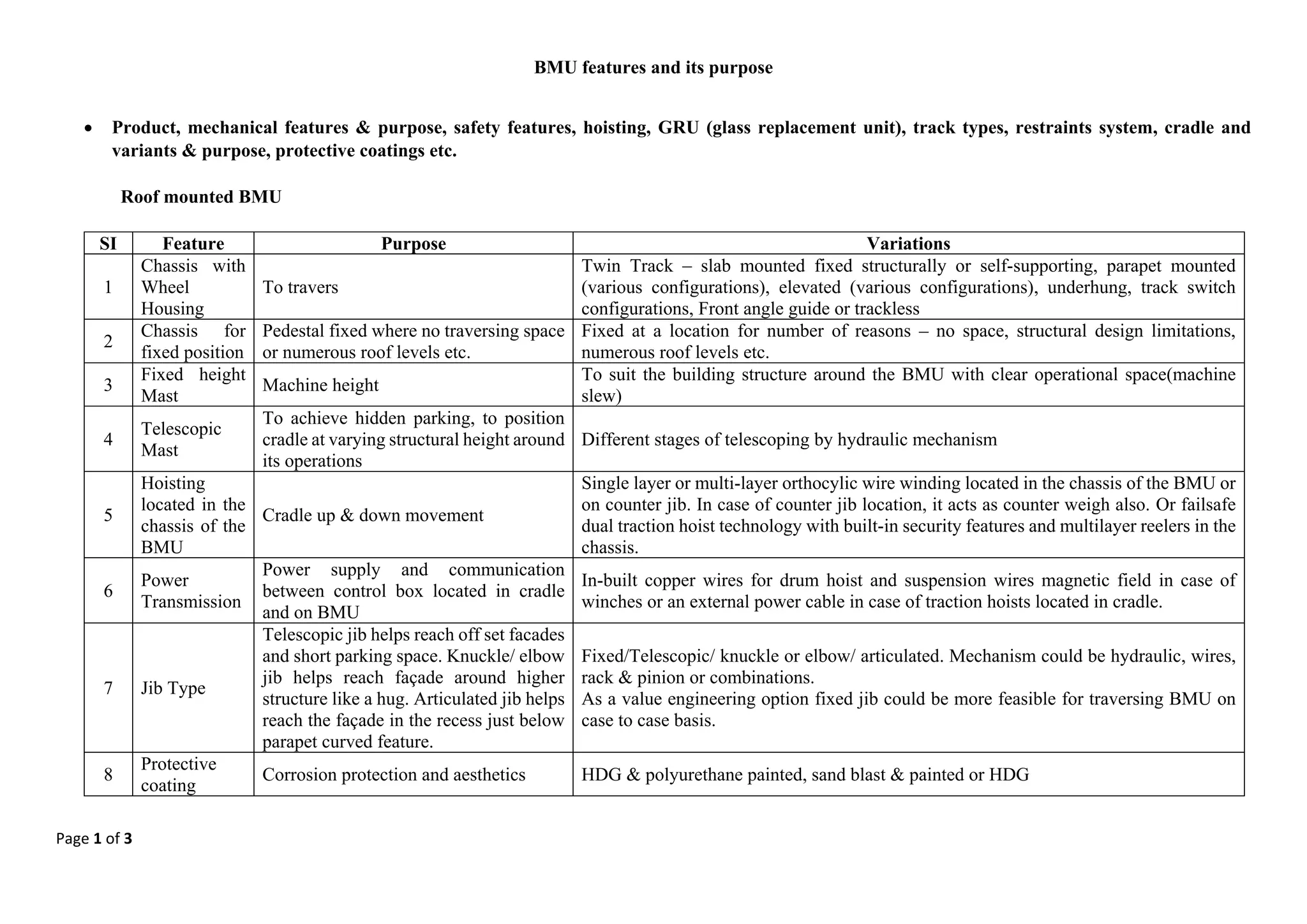

This document describes various features and options for building maintenance units (BMUs). It discusses chassis, mast, hoisting, power transmission, jib, cradle, restraint, and safety features. Variations include track types for the chassis, fixed or telescopic masts, single or multi-layer wire winding for hoisting, copper wires or winches for power transmission, fixed or articulating jibs, and conventional or soft rope restraints. The document also briefly mentions other facade access solutions like monorail systems, davits, gantries, and abseiling.