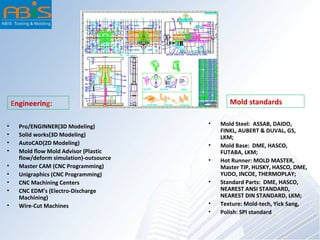

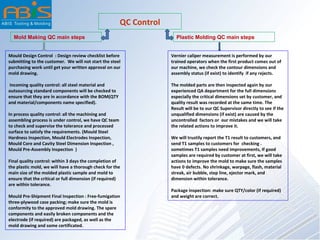

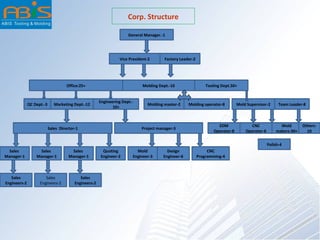

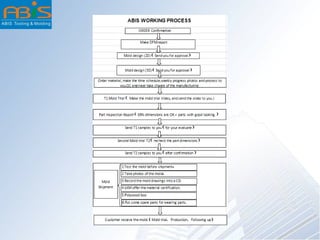

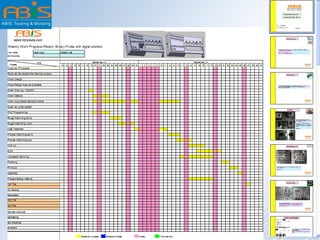

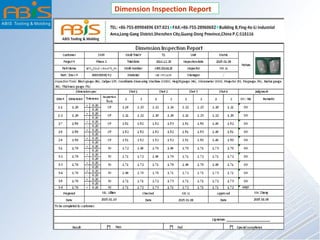

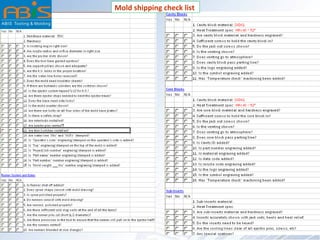

This document provides information about ABIS Mold Technology, including its contact information, company profile, services, facilities, quality control processes, corporate structure, and photos. ABIS Mold was founded in 1996 in Shenzhen, China and focuses on plastic mold manufacturing and molding services. It has advanced equipment and a team of experienced designers and engineers who build molds and provide secondary processing. The company also offers quality control throughout the mold making and molding processes.