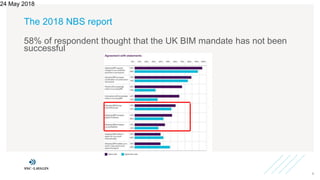

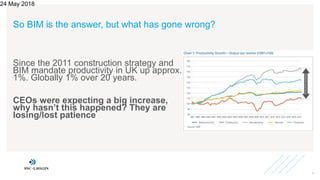

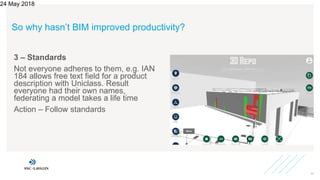

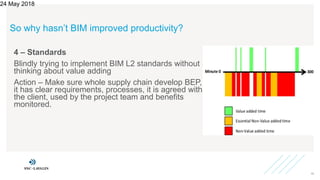

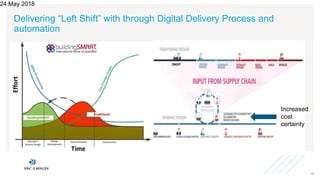

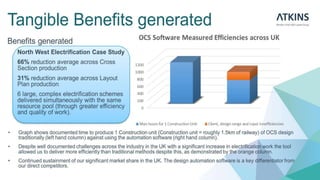

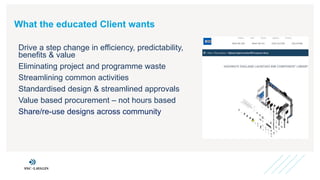

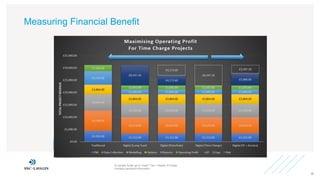

The document discusses the challenges of improving productivity in construction through BIM (Building Information Modeling), highlighting that 30-40% of costs are due to rework. Several reasons for the lack of productivity gains are identified, including unclear information requirements from clients, disconnects in contract structures, and non-adherence to standards. The document emphasizes the necessity for better information management, automation, and standardized workflows to realize potential productivity improvements of up to 20%.