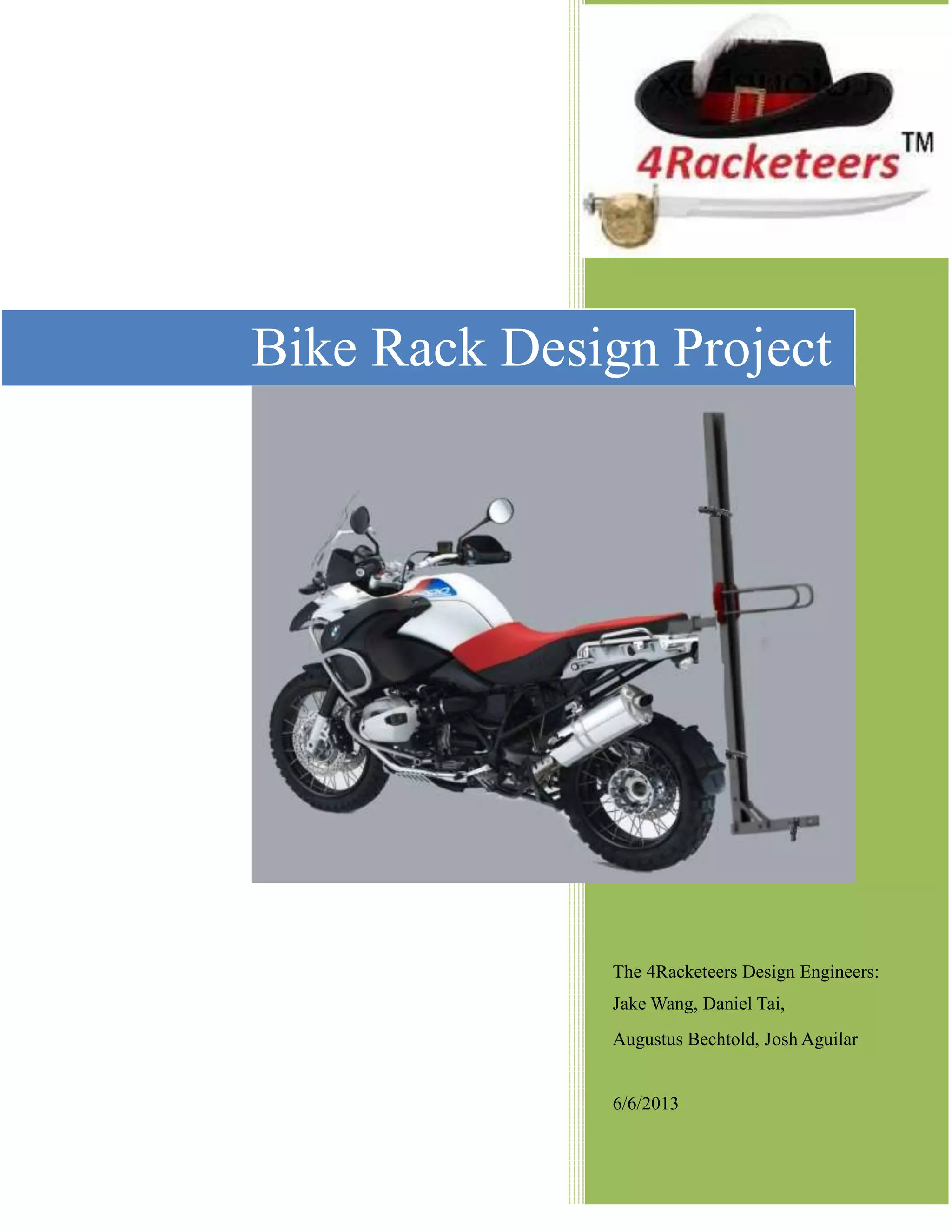

This document presents the design of a bike rack for motorcycles. It includes analyses of the strength, deflection, buckling, and fatigue of the design. The bike rack consists of six parts that are connected to the luggage rack of a BMW GS motorcycle. Analyses were performed on the vertical beam mainframe to verify the design meets requirements for a maximum load of 240 pounds, deflection less than 1 inch, and a lifetime of 10,000 trips. Material properties and dimensions are presented and the analyses show the design is strong enough while being inexpensive and lightweight.

![COPYRIGHT © 2013 JAKE WANG

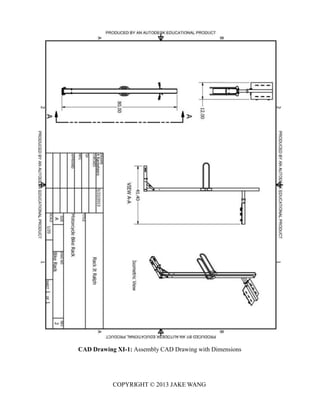

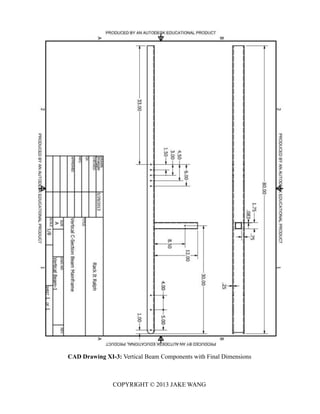

Table XI-1: Vertical Beam Mainframe Final Dimensions/Weight/Cost

Vertical Beam: Design Parameters

Material: A36

Sets H

[inches]

W

[inches]

L

[inches]

t [inches]

3 3 1 1/2 80 1/4

Welded Square Tube: Design Parameters

Material: A513

Sets H

[inches]

W

[inches]

L

[inches]

t [inches]

3 1 1/2 1 1/2 10 3/4

Subtotal Weight [lbs.] 49.25

Subtotal Cost [$] 118.88

Subtotal Deflections

[in]

0.018472](https://image.slidesharecdn.com/jakewangbikerackdesignproject-140430134306-phpapp01/85/Bike-Rack-Design-Project-10-320.jpg)

![3)Table A1-2: Material Properties for Design Parts

Table A-1: Material Properties for our Steel Square Tubing

Table A-2: Material Properties for our Bolt Options

Table A-3:SAE1045 Steel Fatigue S-N Curve

COPYRIGHT © 2013 JAKE WANG

Major Design Component

Steel Tubing

Material/Grade ASTM A500

Steel*

ASTM A513 Steel*

Density (p) 0.284

[lbf/in^3]

Elastic Modulus

(E)

20300 [kpsi] 30000 [kpsi]*

Poisson's ratio (v) 0.292

Yield Strength

(Sy)

45700 [psi] 72000 [psi]

Ultimate Strength

(Su)

58000 [psi] 87000 [psi]

* Assume 30000. No data

found.

Bolt Component

Material/Grade Low Carbon Bolt

**

Grade 2 5 8

Yield Strength (Sy) 57000 [psi] 92000 [psi] 130000

[psi]

Ultimate Strength

(Su)

74000 [psi] 120000[psi] 150000[psi]

Proof Load 55000 [psi] 85000 [psi] 120000[psi]

(low carbon steel)](https://image.slidesharecdn.com/jakewangbikerackdesignproject-140430134306-phpapp01/85/Bike-Rack-Design-Project-22-320.jpg)

![COPYRIGHT © 2013 JAKE WANG

A.5) Detailed Analysis Comparison

i) Table A-: Strength Analysis

Table A-3: Complete Table of Available Dimensions Welded Square Tube Analysis

Welded Square Tube: Design Parameters

Dimensions

Sets H [inches] W [inches] L [inches] t [inches]

1 1 1/4 1 1/4 10 3/16

2 1 1/2 1 1/2 10 1/4

3 1 1/2 1 1/2 10 3/4

Parts Design Parameters

Area Calculations

Sets A [inches^2]

1 2/3

2 1 1/4

3 2 1/4

Parts Design Parameters

Moment of Inertia Calculations

Sets I [inches^4]

1 1/6

2 1/3

3 3/7

Parts Design Parameters

Distance from the edge to Bolt

(e)

Sets e [inches]

1 1

1 1 1/2

1 2

2 1

2 1 1/2

2 2

3 1

3 1 1/2

3 2](https://image.slidesharecdn.com/jakewangbikerackdesignproject-140430134306-phpapp01/85/Bike-Rack-Design-Project-27-320.jpg)

![COPYRIGHT © 2013 JAKE WANG

ii) Table A-: Deflection Analysis

Parts Material

Strength Set A500 Von

Mises

<Sy A513 Von

Mises

<Sy Best Set

Ranking

Tensile Stress [psi] 1 16493 14400 Yes 3709 3138 Yes 3

24/25 1/11 6/13

2 9038 7253 Yes 2448 1360 Yes 2

10/13 1/3

3 7253 7253 Yes 1360 1360 Yes 1

1/3 1/3

Compressive Stress 1 -16493 - Yes -3138 -3138 Yes 3

[psi] 24/25 14400 6/13 6/13

(Note: A500: 2 -9038 -7253 Yes -1360 -1360 Yes 2

Sy=45700 [psi]) 10/13 1/3

(Note: A513: 3 -7253 -7253 Yes -1360 -1360 Yes 1

Sy=72000 [psi]) 1/3 1/3

Best Material

Ranking

1 2

Parts Material

Deflections Set A500 A513

Vertical Deflection [in.] 1 19/400 9/280

(Note: E=20300 [kpsi]) 1 21/131 32/295

1 19/50 9/35

2 19/800 9/560

2 21/262 16/295

2 19/100 9/70

3 15/812 1/80

3 25/401 17/403

3 103/697 1/10

Deflections for design part

[in.]

1 19/400 9/280

2 19/800 9/560

3 15/812 1/80 Deflection

Difference

Min Deflections for design

part [in.]

Set

3

15/812 1/80 2/335](https://image.slidesharecdn.com/jakewangbikerackdesignproject-140430134306-phpapp01/85/Bike-Rack-Design-Project-28-320.jpg)

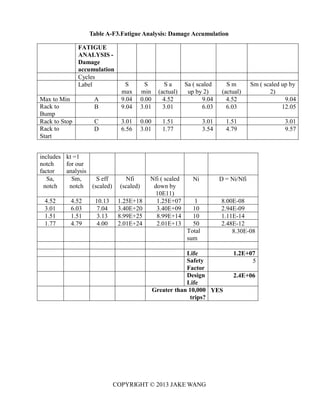

![COPYRIGHT © 2013 JAKE WANG

iii) Table A-Buckling Analysis

iv) Table A-Fatigue Analysis

Table A-F1.Fatigue Analysis

Parts Material

Buckling Set A500 <Sy [Yes/No] A513 <Sy [Yes/No]

Tensile Stress [psi] 1 0 0 0 0

2 0 0 0 0

3 0 0 0 0

Compressive Stress [psi] 1 0 0 0 0

2 0 0 0 0

3 0 0 0 0

(Comments: Due to no compressive force acting on the vertical beam, the beam would not

buckle.)

Vertical Beam Welded Tube Fatigue Analysis:

GEOMETRY MATERIAL A1045 Steel

D 0.85 inch Sy 105 ksi

Su 84 ksi

I 0.3385 inch^4 A 152 ksi, (for fully

reversed loading)

A N/A inch^2 b -0.065

c 0.7500 inch

Kt, notch 1.0000 (unnotched)

LOADING

Maneuver Fx [lbs] Fy [lbs] P [lbs] V [lbs] M

[lb*in]

Stress @ Welded Tube

(Mc/I) [ksi]

Load Bike 0 0 0 0 0 0.00

On rack 0 80 0 80 1360 3.01

Start 40 80 40 80 2960 6.56

Bump 0 240 0 240 4080 9.04

Stop -60 80 -60 80 -1040 -2.30

On rack 0 80 0 80 1360 3.01

Unload

Bike

0 0 0 0 0 0](https://image.slidesharecdn.com/jakewangbikerackdesignproject-140430134306-phpapp01/85/Bike-Rack-Design-Project-29-320.jpg)

![COPYRIGHT © 2013 JAKE WANG

Table A-W1.Vertical Beam and Welded Tube Weight Analysis

Table A-C1.Vertical Beam and Welded Tube Cost Analysis

Components Weight

Sets Vertical Beam [lb] Welded Tube [lb] Bolts

[lb]

Total Weight [lb] Selection

Ranking

1 34 2 1/4 36 18/61 1

2 45 1/2 3 5/9 1/4 49 9/35 2

3 42 3/5 6 2/5 1/4 49 9/35 2

Vertical Beam and Welded Tube Cost

Analysis

Material: C

Channel

A-36

Steel

Welded

Tube

A500

Steel

Components Costs

Sets Vertical

Beam [$]

Welded

Tube [$]

Bolts

[$]

Material

Cost [$]

Labor

Cost

[$]

Total

Cost

[$]

Selection

Ranking

1 40.96 21.66 2 64.62 69.30 133.92 1

2 52.00 13.32 2 67.32 69.53 136.85 2

3 51.84 18.00 2 71.84 69.91 141.75 3

Vertical Beam and Welded Tube Cost

Analysis

Material: C

Channel

A-36

Steel

Welded

Tube

A513

Steel

Components Costs

Sets Vertical

Beam [$]

Welded

Tube [$]

Bolts

[$]

Material

Cost [$]

Labor

Cost

[$]

Total

Cost

[$]

Selection

Ranking

1 40.96 6.62 2 49.58 69.30 118.88 1

2 52.00 6.24 2 60.24 69.53 129.77 2

3 51.84 7.82 2 61.66 69.91 131.57 3](https://image.slidesharecdn.com/jakewangbikerackdesignproject-140430134306-phpapp01/85/Bike-Rack-Design-Project-32-320.jpg)

![COPYRIGHT © 2013 JAKE WANG

Table A-L: Vertical Beam and Welded Tube Labor Cost Analysis

Vertical Beam and Welded Tube Labor Cost Analysis

Material: C

Channel

A-36

Steel

Welded

Tube

A500 or

513 Steel

Sets 1 2 3

Processes Unit Cost

[$]

# of Units

or Length

[cm]

Subtotal

Cost [$]

Unit

Cost

[$]

# of Units

or Length

[cm]

Subtotal

Cost [$]

Unit

Cost

[$]

# of Units

or Length

[cm]

Subtotal

Cost [$]

Vertical

Tube

Drilled $ 5 $ $ 5 $ $ 5 $

holes <

25.4 mm

dia. 0.35 1.75 0.35 1.75 0.35 1.75

Saw or $ 40.54 $ $ 40.54 $ $ 40.54 $

tubing cuts 0.40 16.22 0.40 16.22 0.40 16.22

Welded

Tube

Tube end $ 1 $ $ 1 $ $ 1 $

preparation

for

welding 0.75 0.75 0.75 0.75 0.75 0.75

Weld $ 1.69 $ $ 3.18 $ $ 5.72 $

0.15 0.25 0.15 0.48 0.15 0.86

Tube cut $ 35.56 $ $ 35.56 $ $ 35.56 $

0.15 5.33 0.15 5.33 0.15 5.33

Assembly

Assemble, $ 12 $ $ 12 $ $ 12 $

>20 kg,

Line-on-

Line 3.75 45.00 3.75 45.00 3.75 45.00

Total $ Total $ Total $

Labor Labor Labor

Cost 69.30 Cost 69.53 Cost 69.91

Ranking (Least to

Highest Price)

1 2 3](https://image.slidesharecdn.com/jakewangbikerackdesignproject-140430134306-phpapp01/85/Bike-Rack-Design-Project-33-320.jpg)