This document presents a study analyzing the structural optimization of car wheel rims. Researchers modeled wheel rims from Renault and Volkswagen vehicles using CATIA and analyzed them using ANSYS under an inflation pressure load. Various materials including steel alloy, aluminum alloy, magnesium alloy, titanium alloy, and a carbon composite were considered. The optimized models showed lower stresses and deformations compared to the actual models. Titanium alloy performed best but is not affordable; the study suggests carbon composite as a lighter, stronger alternative material for wheel rims.

![Jtasr.com Case Study

J. Technological Advances and Scientific Res./eISSN- 2454-1788, pISSN- 2395-5600/ Vol. 2/ Issue 02/ Apr-June 2016 Page 105

MODEL OPTIMIZATION AND STRUCTURAL ANALYSIS OF CAR RIM

K. N. D. Malleswara Rao1, M. N. V. Stalin Babu2, V. Sai Narayana3, V. Vineeth Kumar4

1Assistant Professor, Department of Mechanical Engineering, Andhra Loyola Institute of Engineering and Technology.

2B. Tech. Student, Department of Mechanical Engineering, Andhra Loyola Institute of Engineering and Technology.

3B. Tech. Student, Department of Mechanical Engineering, Andhra Loyola Institute of Engineering and Technology.

4B. Tech. Student, Department of Mechanical Engineering, Andhra Loyola Institute of Engineering and Technology.

ABSTRACT

Automotive organizations are paying their major interest in the weight reduction of components to minimize fuel cost. This

weight can be reduced by introducing new materials and manufacturing processes with optimization of design.[1] In this paper, an

attempt is made to minimize the stress and deformation of the wheel by replacing the aluminium alloy with other alloy materials

and composites. This gave a new approach in the field of optimization of car wheel rim. In this work, the modelling is done by using

CATIA V5 R20 and analysis is made by using ANSYS 14.5.[2] The analysis also shows that after the optimization, the stresses generated

from the wheel rim will be below the yield stress.

KEYWORDS

ANSYS, CATIA, Pressure Load, Renault, Volkswagen.

HOW TO CITE THIS ARTICLE: Rao KNDM, Babu MNVS, Narayana VS, et al. Model optimization and structural analysis of car rim. J.

Technological Advances and Scientific Res. 2016;2(2):105-114, DOI: 10.14260/jtasr/2016/17

1. INTRODUCTION

The rim of a wheel is the outer circular design of the metal on

which the inside edge of the tire is mounted on vehicles such

as automobiles.

1.1 Types of Rims

1. Wire spoke wheel

2. Steel disc wheel

3. Light alloy wheel

a. Aluminium alloy wheel

b. Magnesium alloy wheel

c. Titanium alloy wheel

d. Composite material wheel

Different materials have different effects on the strength,

stability and life of the wheel rim. Similarly, even changing the

thickness of the wheel by a few inches can drastically affect the

properties of the wheel rim.[3] In this paper, we have analysed

a wheel rim by varying the thickness of the wheel and also by

applying different materials.

1.2 Materials and their Characteristics

Steel has an excellent feature of high fatigue strength. It

can withstand to maximum number of cyclic loads.[4] But

due to its weight, the fuel consumption is more.

Aluminium alloy is a metal with features of excellent

lightness, thermal conductivity, physical characteristics of

casting, low heat, machine processing and reutilizing,

etc.[5] This metal’s main advantage is decreased weight,

high precision and design choices of the wheel.

Magnesium alloy is about 30% lighter than aluminium

and also admirable as for size stability and impact

resistance.[6] However, its use is mainly restricted to

racing, which needs the features of weightlessness and

high strength.

Financial or Other, Competing Interest: None.

Submission 12-03-2016, Peer Review 21-03-2016,

Acceptance 10-04-2016, Published 11-04-2016.

Corresponding Author:

K. N. D. Malleswara Rao,

D. No. 61-24-16,

Tagore St. RL Nagar,

Vijayawada-520013.

E-mail: nottymalli@gmail.com

DOI: 10.14260/jtasr/2016/17

Titanium is an admirable metal for corrosion resistance

and strength about 2.5 times compared with aluminium,

but it is inferior due to machine processing, designing and

more cost.[7]

Composite material wheel is different from the light alloy

wheel and it is developed mainly for low weight. However,

this wheel has inadequate consistency against heat and for

best strength.[8] For analysis in this paper, polyether ether

ketone is taken as polymer matrix composite and

reinforced with 30% carbon.

2. MODELLING OF RIM USING CATIA VR20

Sl.

No.

Specification Value

1 Rim Width 230 mm

2 Wheel Diameter 470 mm

3 Offset 20 mm

4 Number of spokes 5

5 Rim thickness 3 mm

6 Bolt diameter 16 mm

7 Number of bolt holes 5

Table 1: Renault Rim Specifications

Sl.

No.

Specification Value

1 Rim Width 250 mm

2 Wheel Diameter 450 mm

3 Offset 25 mm

4 Number of spokes 10

5 Rim thickness 5 mm

6 Bolt diameter 20 mm

7 Number of bolt holes 5

Table 2: Volkswagen Rim Specifications](https://image.slidesharecdn.com/bc8b8d65-ea26-4d39-8a99-6090377db742-160411101149/75/Model-Optimization-and-structural-Analysis-of-a-Car-Rim-1-2048.jpg)

![Jtasr.com Case Study

J. Technological Advances and Scientific Res./eISSN- 2454-1788, pISSN- 2395-5600/ Vol. 2/ Issue 02/ Apr-June 2016 Page 106

Fig. 1: Volkswagen Actual Model

Fig. 2: Renault Actual Model

Fig. 3: Volkswagen Optimized Model

Fig. 4: Renault Optimized Model

3. ANALYSIS OF WHEEL RIM

Auto mesh is done in ANSYS workbench to solve the

differential equations, which are a combination of structured

and unstructured mesh.[9] The imported file geometry

undergoes meshing, after which boundary conditions are

applied to the physical domain. Wheel rim is considered as it

is in static condition and the boundary conditions like

pressures are applied. As the problem is taken in statics, the

entire load on the wheel rim will be distributed throughout the

rim because of the air.

Fig. 5: Imported Model in ANSYS

Fig. 6: Meshed Model

Fig. 7: Imported Model in ANSYS](https://image.slidesharecdn.com/bc8b8d65-ea26-4d39-8a99-6090377db742-160411101149/85/Model-Optimization-and-structural-Analysis-of-a-Car-Rim-2-320.jpg)

![Jtasr.com Case Study

J. Technological Advances and Scientific Res./eISSN- 2454-1788, pISSN- 2395-5600/ Vol. 2/ Issue 02/ Apr-June 2016 Page 107

Fig. 8: Meshed Model

3.1 Boundary Conditions and Loading:

Displacements

A. Translation in x, y, z directions is zero.

B. Rotation in x, y, z direction is zero.

These conditions are applied on the five holes provided on

the rim.

Loading

After constraining the meshed model, the model is subjected

to an inflation pressure of 0.24131 MPa. Later the solution is

done in the SOLVER module.[10] Next solution results such as

stress, displacement are calculated for all the materials.

Fig. 9: Displacement

Fig. 10: Load Applied

3.2 Material Properties

MATERIAL/

PROPERTIES

YOUNG’S

MODULUS

POISSON’S

RATIO

DENSITY

[11]STEEL ALLOY 2e+11 pa 0.3

7850

kg/m^3

ALUMINIUM

ALLOY

7.1e+10 pa 0.33

2700

kg/m^3

MAGNESIUM

ALLOY

4.5e+10 pa 0.35

1800

kg/m^3

[12] TITANIUM

ALLOY

9.6e+10 pa 0.36

4620

kg/m^3

CARBON

COMPOSITE

MATERIAL

2.23e+11

pa

0.44

2200

kg/m^3

Table 3: Material Properties

4. RESULTS AND DISCUSSION

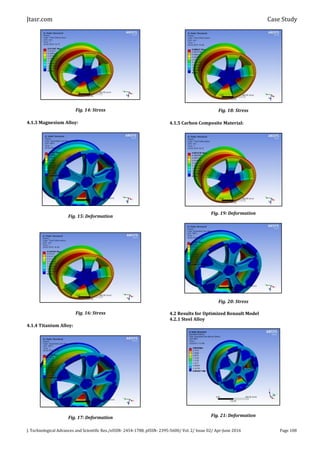

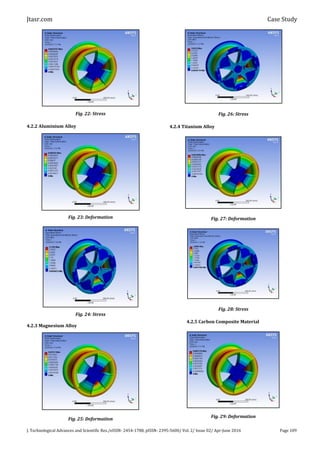

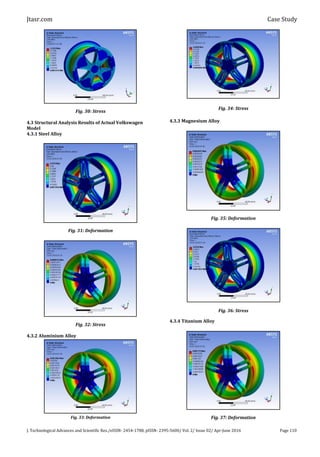

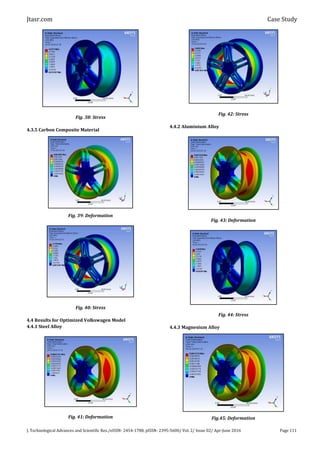

4.1 Structural Analysis Results for Actual Renault Model

4.1.1 Steel Alloy:

Fig. 11: Deformation

Fig. 12: Stress

4.1.2 Aluminium Alloy

Fig. 13: Deformation](https://image.slidesharecdn.com/bc8b8d65-ea26-4d39-8a99-6090377db742-160411101149/85/Model-Optimization-and-structural-Analysis-of-a-Car-Rim-3-320.jpg)