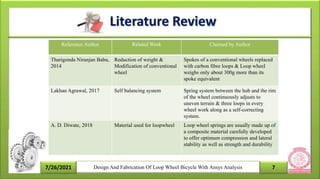

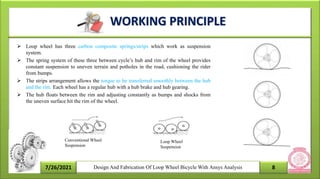

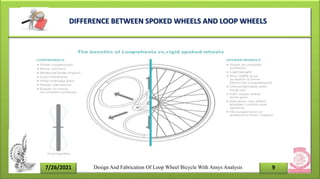

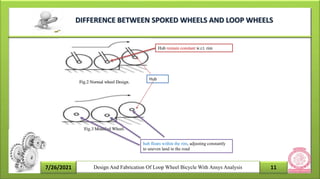

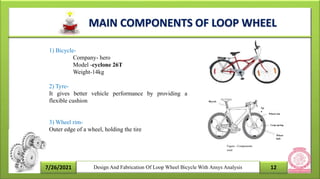

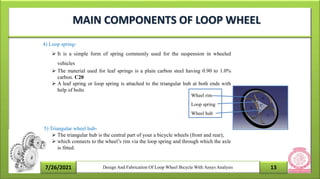

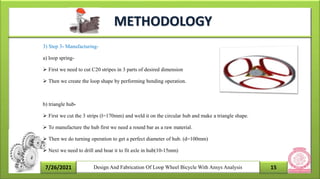

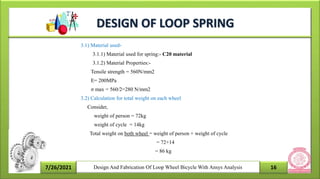

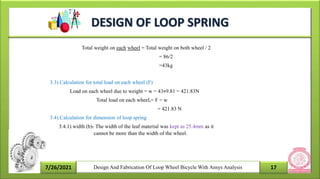

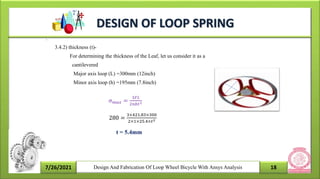

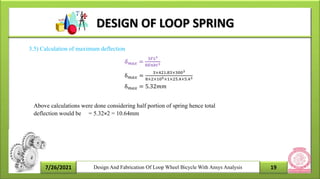

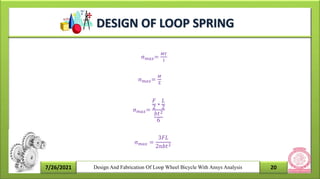

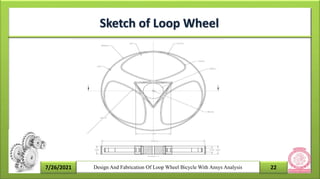

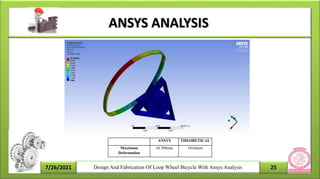

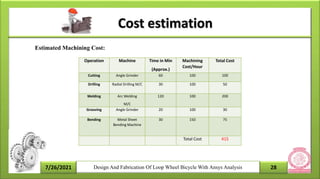

The document details the design and fabrication of a loop wheel bicycle, emphasizing its integral suspension system that enhances ride comfort and performance. It discusses the methodology, including CAD modeling and ANSYS analysis for stress and deformation, as well as the advantages and limitations of loop wheels compared to conventional spoked wheels. Future applications and improvements in cycling and other vehicles are also suggested.