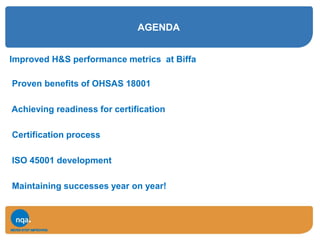

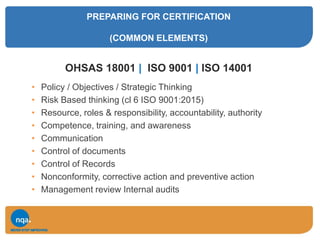

The document discusses the implementation and benefits of OHSAS 18001 in improving health and safety performance metrics at Biffa, highlighting a 35% reduction in serious accidents. It details the certification process, emphasizing systematic approaches, risk management, and continuous improvement. The content also covers the transition from OHSAS 18001 to ISO 45001 and offers resources for staying updated on legal and regulatory requirements.