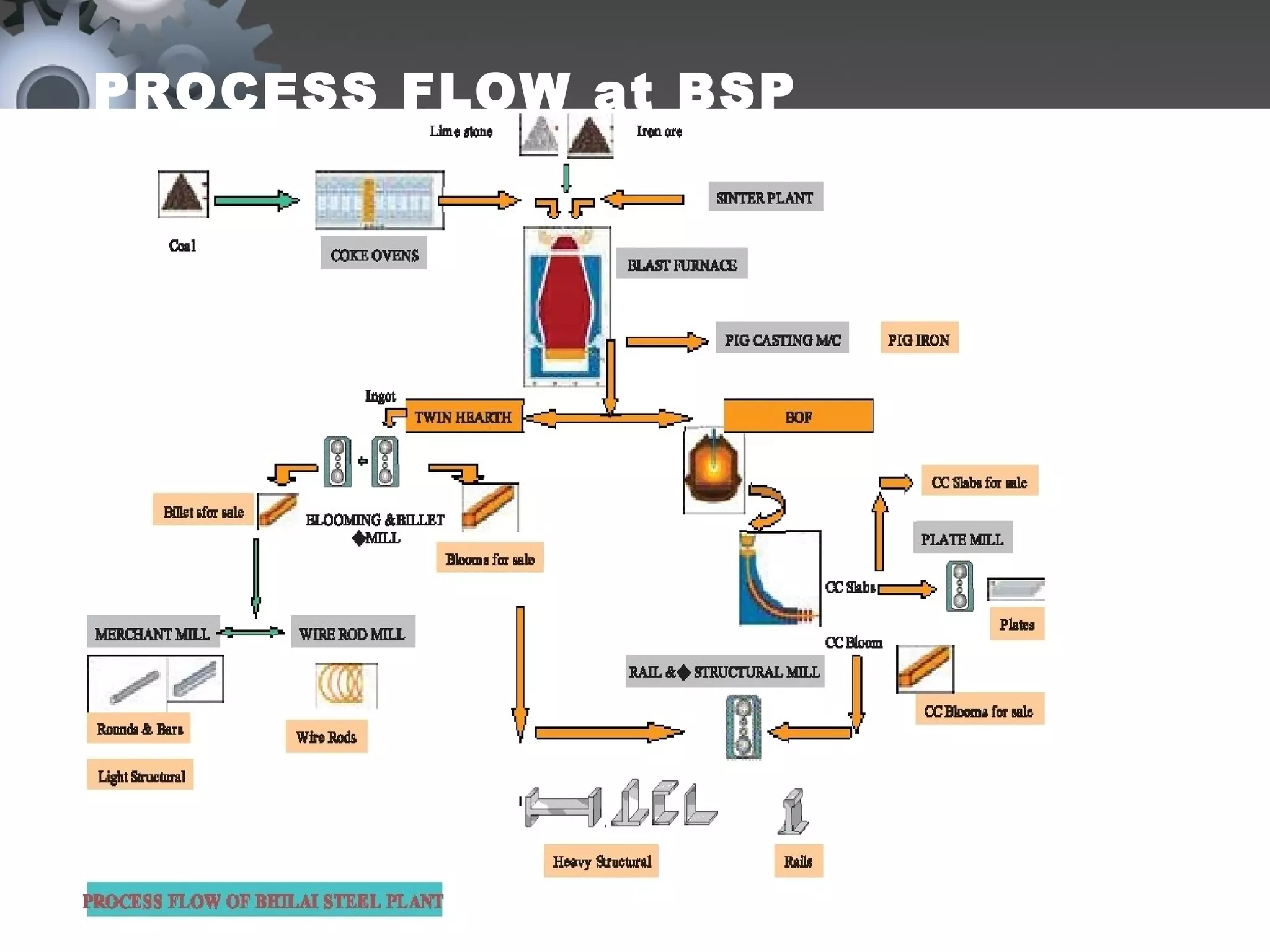

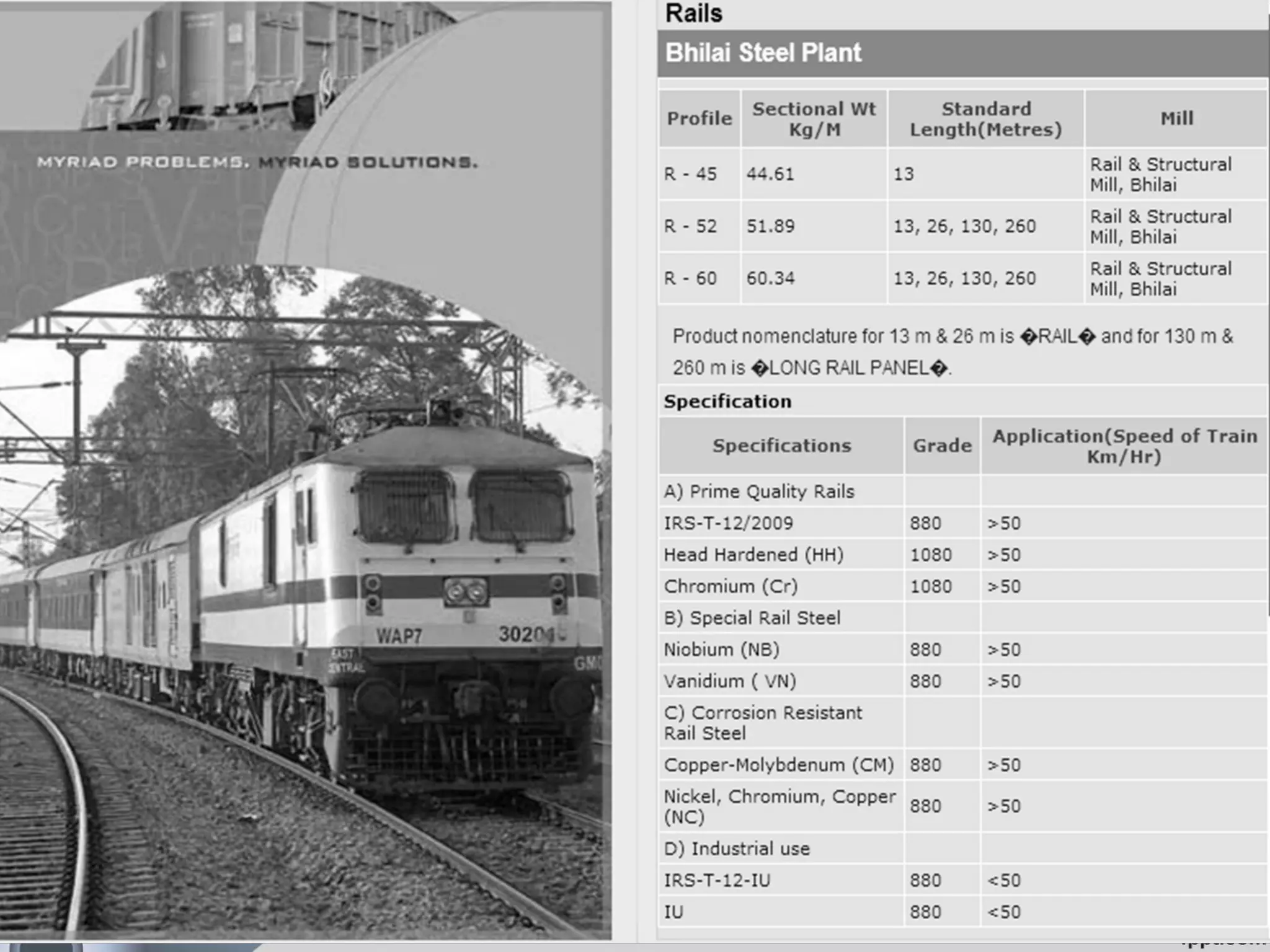

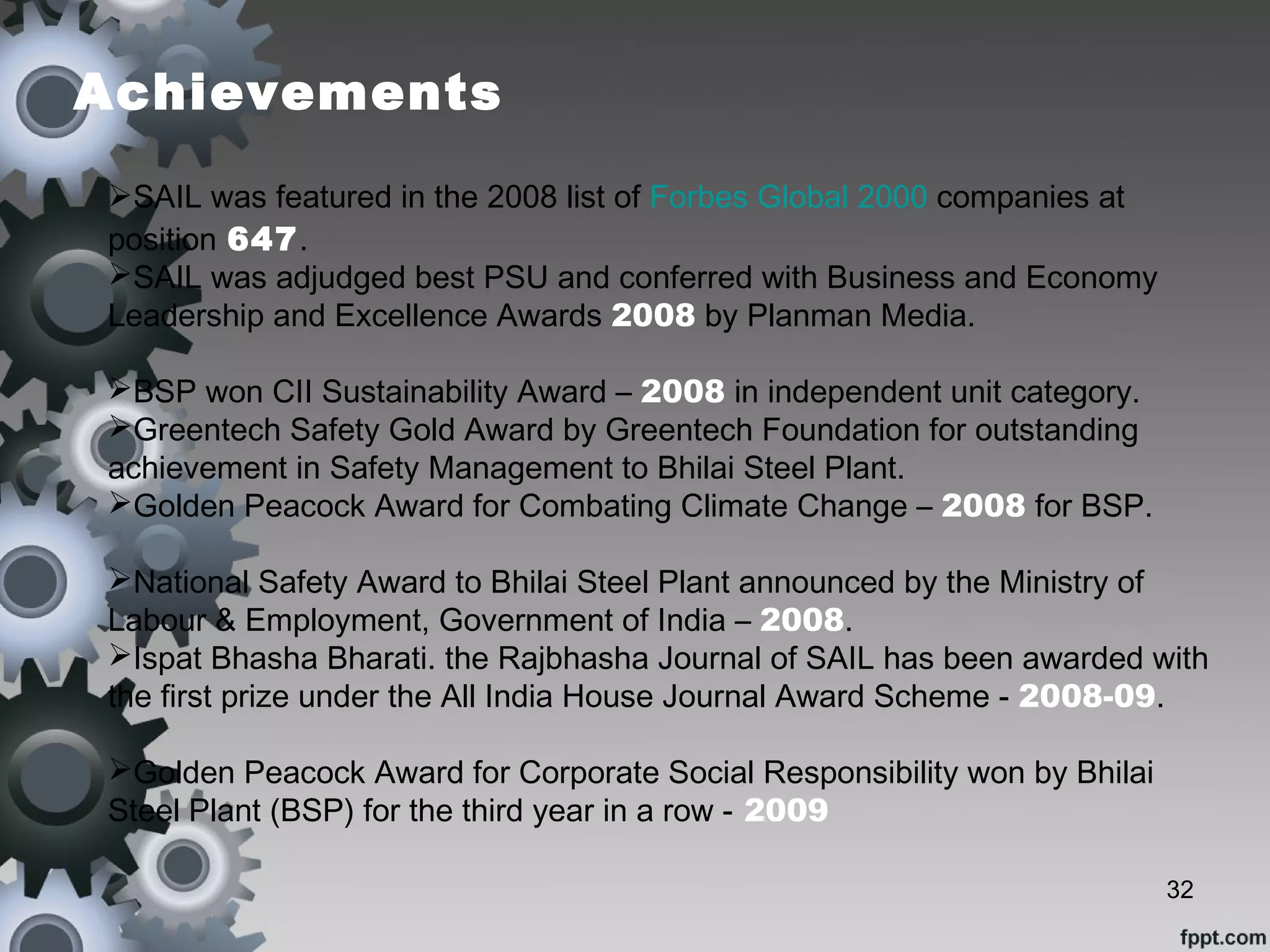

Bhilai Steel Plant (BSP), established in 1959 and operated by Steel Authority of India Limited, is a key public sector steel production unit with an annual capacity of 3.153 million tonnes of saleable steel, specializing in rails and plates. It has garnered multiple awards for its integrated steel production capabilities, achieving high-quality standards and environmentally sustainable practices. BSP is significant for supplying long rail tracks and has a comprehensive product range including structural and wire products, maintaining international certifications for quality and environmental management.